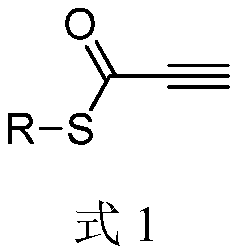

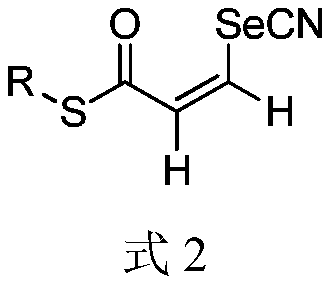

Environment-friendly preparation method of Z-3-thiocyanate thioacrylate compound

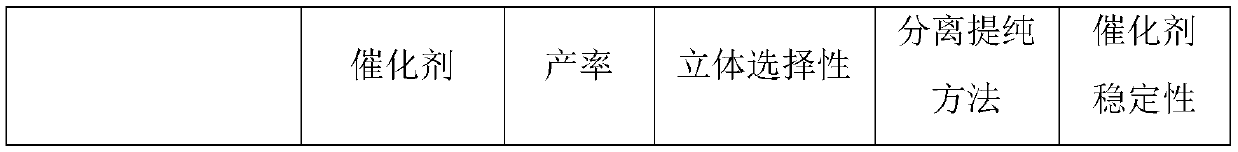

A technology of ester-based thioacrylate, Z-3-, applied in the field of organic intermediate synthesis, can solve the problems of limited practical application, no commercial products, complicated separation process, etc., achieves quantitative raw material conversion rate, low price, The effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0050] Following examples 1~3 all react by following reaction equation:

[0051]

[0052] The specific operation steps are: in a 20mL reaction tube, sequentially add propyne thioacid methyl ester (10mmol), potassium selenocyanate (12mmol, 1.16g), water (10mmol, 0.18g), lactic acid (30mmol, 2.70g) , the resulting mixture was reacted in a 30W / 44KHz ultrasonic reaction device for 30 minutes. After the reaction, 13.5ml of water and lactic acid were added to form an aqueous lactic acid solution. Z-3-selenocyanatopropenylthioate was insoluble in the aqueous lactic acid solution and precipitated, separated, and vacuum-dried to calculate the weight.

Embodiment 1

[0054] raw material: Target product:

[0055] S-(p-tolyl)(Z)-3-selenocyanatoprop-2-enethioate:

[0056] Yield: 95%

[0057] 1 H NMR (400MHz, CDCl 3 )δ7.79(d, J=8.0Hz, 1H), 7.36(d, J=8.0Hz, 2H), 7.29(d, J=8.0Hz, 2H), 7.04(d, J=8.0Hz, 1H) ,2.41(s,3H).

[0058] 13 C NMR (100MHz, CDCl 3 )δ191.3, 140.9, 138.7, 134.3, 130.5, 124.7, 121.9, 105.7, 21.4.

[0059] HRMS Calcd(EI)m / z for C 11 h 9 NOSSe:[M] + 282.9570,found: 282.9574.

Embodiment 2

[0061] raw material: Target product:

[0062] S-phenyl(Z)-3-selenocyanatoprop-2-enethioate:

[0063] Yield: 94%

[0064] 1 H NMR (400MHz, CDCl 3 )δ7.53–7.52(m,2H),7.45–7.42(m,2H),7.38–7.37(m,1H),7.20(d,J=9.6Hz,1H),6.37(d,J=9.6Hz ,1H).

[0065] 13 C NMR (100MHz, CDCl 3 )δ186.1, 148.2, 134.6, 131.0, 129.4, 129.1, 128.4, 118.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com