Preparation method and application method of graphene-nano polytetrafluoroethylene composite modified filler

A polytetrafluoroethylene, compound modification technology, applied in the field of new materials, can solve problems such as difficult to realize industrial production, environmental protection performance to be discussed, efficiency of impurity removal reaction, etc., to achieve improved compatibility, large industrial application prospects, dispersion good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

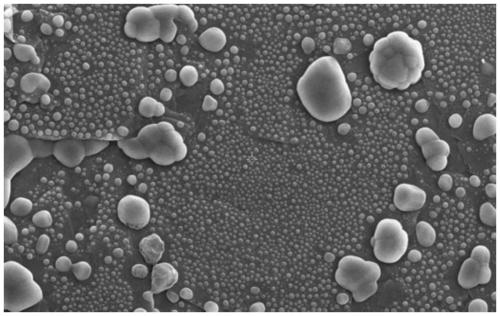

[0026] Example 1, the present invention specifically prepares graphene-nano polytetrafluoroethylene composite modified filler through the following flow process:

[0027] First, take 10 parts by weight of powdered graphene and add it to 800 parts by weight of deionized water, and heat it to 80°C in a water bath and mix and stir to fully dissolve the graphene to obtain solution A; take 2 parts by weight of silane coupling agent 15 parts by weight of ethanol and 1 part by weight of deionized water were mixed and stirred for 30 minutes to obtain solution B, and 5 parts by weight were added to solution A, and then the reaction temperature was kept at 80°C, reacted in a water bath for 3 hours, and then cooled to room temperature , filtered and washed with deionized water to obtain a modified graphene filler M with lipophilic properties. Pretreatment with a coupling agent can prevent the fillers from stacking and agglomerating due to van der Waals force. Carry out batching according...

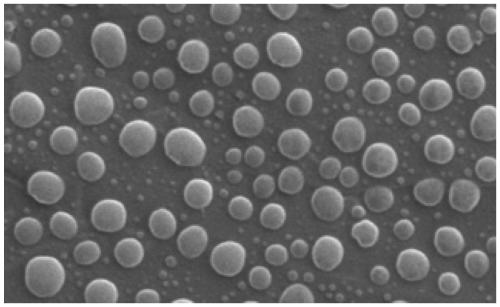

Embodiment 2

[0034] First, take 10 parts by weight of powdered graphene and add it to 800 parts by weight of deionized water, and heat it to 80°C in a water bath and mix and stir to fully dissolve the graphene to obtain solution A; take 2 parts by weight of silane coupling agent 15 parts by weight of ethanol and 1 part by weight of deionized water were mixed and stirred for 30 minutes to obtain solution B, and 5 parts by weight were added to solution A, and then the reaction temperature was kept at 80°C, reacted in a water bath for 3 hours, and then cooled to room temperature , filtered and washed with deionized water to obtain a modified graphene filler M with lipophilic properties. Pretreatment with a coupling agent can prevent the fillers from stacking and agglomerating due to van der Waals force. Carry out batching according to graphene filler M and nano polytetrafluoroethylene weight ratio is 1:5, and add the water-ethanol mixed solution that the mass ratio of adding is 3:2 and stir an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

| Coefficient of friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com