High-strength wear-resistant aluminum alloy material and preparation method thereof

An aluminum alloy material and aluminum alloy technology, applied in the field of aluminum alloy materials, can solve the problems of insufficient strength and low wear resistance, and achieve the effects of low production cost, good wear resistance and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

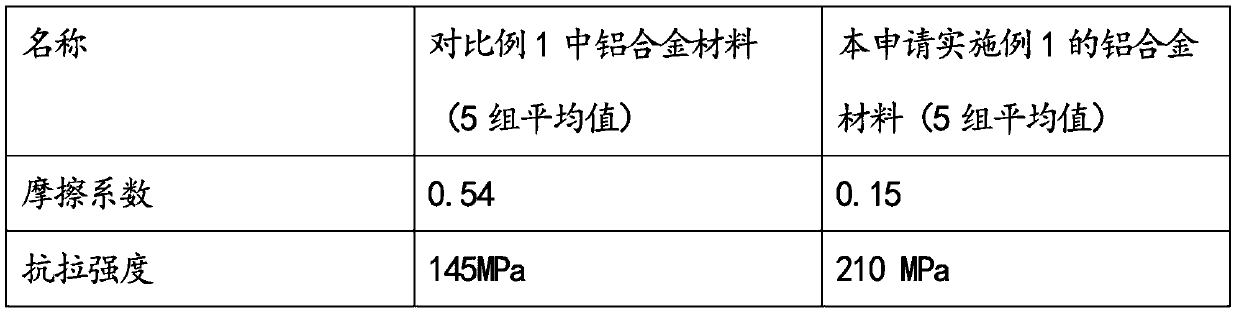

Embodiment 1

[0025] A high-strength and wear-resistant aluminum alloy material includes an aluminum alloy substrate and phosphide and nickel compounds attached to the aluminum alloy substrate by electroless plating.

[0026] The preparation method comprises the following steps:

[0027] (1) Melting: add the aluminum source into the melting furnace in proportion to melt to 740°C, then add the silicon source, titanium source, and manganese source in proportion, continue to keep warm at 750°C, and obtain the aluminum alloy solution after all the alloying elements are melted;

[0028] (2) Refining: the temperature of the aluminum alloy solution in the step (1) is 740° C., and nitrogen gas is introduced for refining treatment to obtain a refined product;

[0029] (3) Standing: the refined product obtained in step (2) is left standing, so that the temperature of the aluminum alloy solution is stabilized at 740° C.;

[0030] (4) Casting: casting the aluminum alloy solution after standing in step...

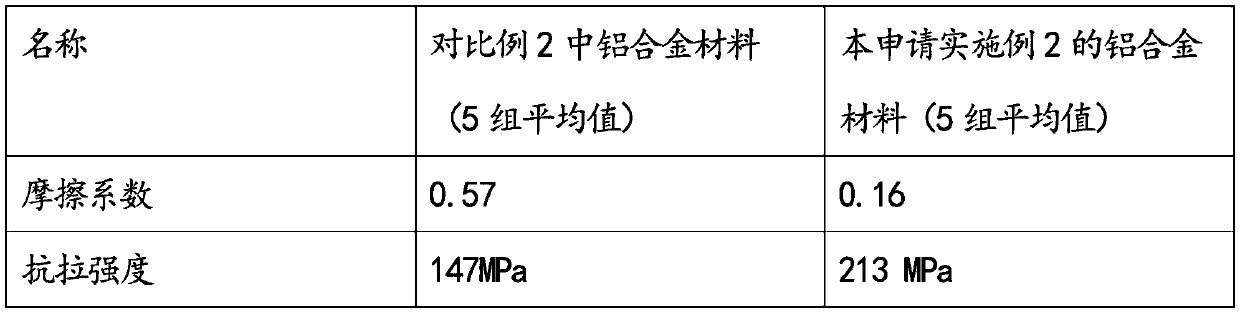

Embodiment 2

[0046] A high-strength and wear-resistant aluminum alloy material includes an aluminum alloy substrate and phosphide and nickel compounds attached to the aluminum alloy substrate by electroless plating.

[0047] The preparation method comprises the following steps:

[0048](1) Melting: add the aluminum source into the melting furnace in proportion to melt to 750°C, then add the silicon source, titanium source, and manganese source in proportion, continue to keep warm at 760°C, and obtain the aluminum alloy solution after all the alloying elements are melted;

[0049] (2) Refining: the temperature of the aluminum alloy solution in the step (1) is 750° C., and nitrogen gas is introduced for refining treatment to obtain a refined product;

[0050] (3) Standing: the refined product obtained in step (2) is left standing, so that the temperature of the aluminum alloy solution is stabilized at 750° C.;

[0051] (4) Casting: casting the aluminum alloy solution after standing in step ...

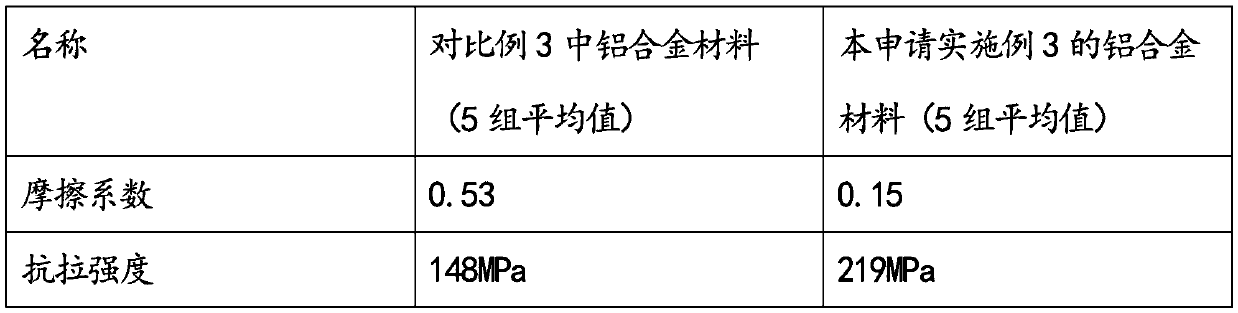

Embodiment 3

[0067] A high-strength and wear-resistant aluminum alloy material includes an aluminum alloy substrate and phosphide and nickel compounds attached to the aluminum alloy substrate by electroless plating.

[0068] The preparation method comprises the following steps:

[0069] (1) Melting: add the aluminum source into the melting furnace in proportion to melt to 740°C, then add the silicon source, titanium source, and manganese source in proportion, continue to keep warm at 750°C, and obtain the aluminum alloy solution after all the alloying elements are melted;

[0070] (2) Refining: the temperature of the aluminum alloy solution in the step (1) is 740° C., and nitrogen gas is introduced for refining treatment to obtain a refined product;

[0071] (3) Standing: the refined product obtained in step (2) is left standing, so that the temperature of the aluminum alloy solution is stabilized at 740° C.;

[0072] (4) Casting: casting the aluminum alloy solution after standing in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com