400 MPa stage reinforcing steel bar and manufacturing method thereof

A manufacturing method and 400mpa technology, applied in the field of metallurgy, can solve the problems of reducing alloy content, limitation, and high niobium alloy element content, and achieve the effects of improving processing and application performance, reducing alloy costs, and flexible combination methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be described in detail below, obviously, the described embodiments are only some of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

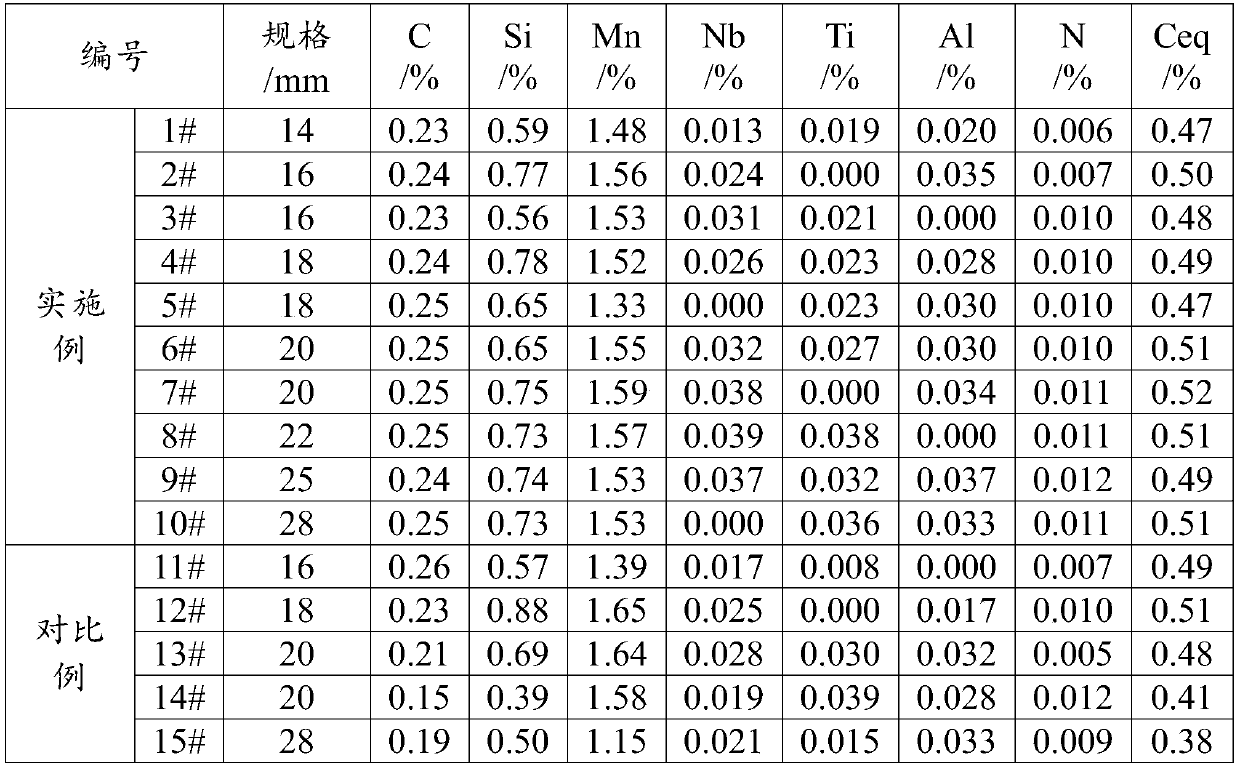

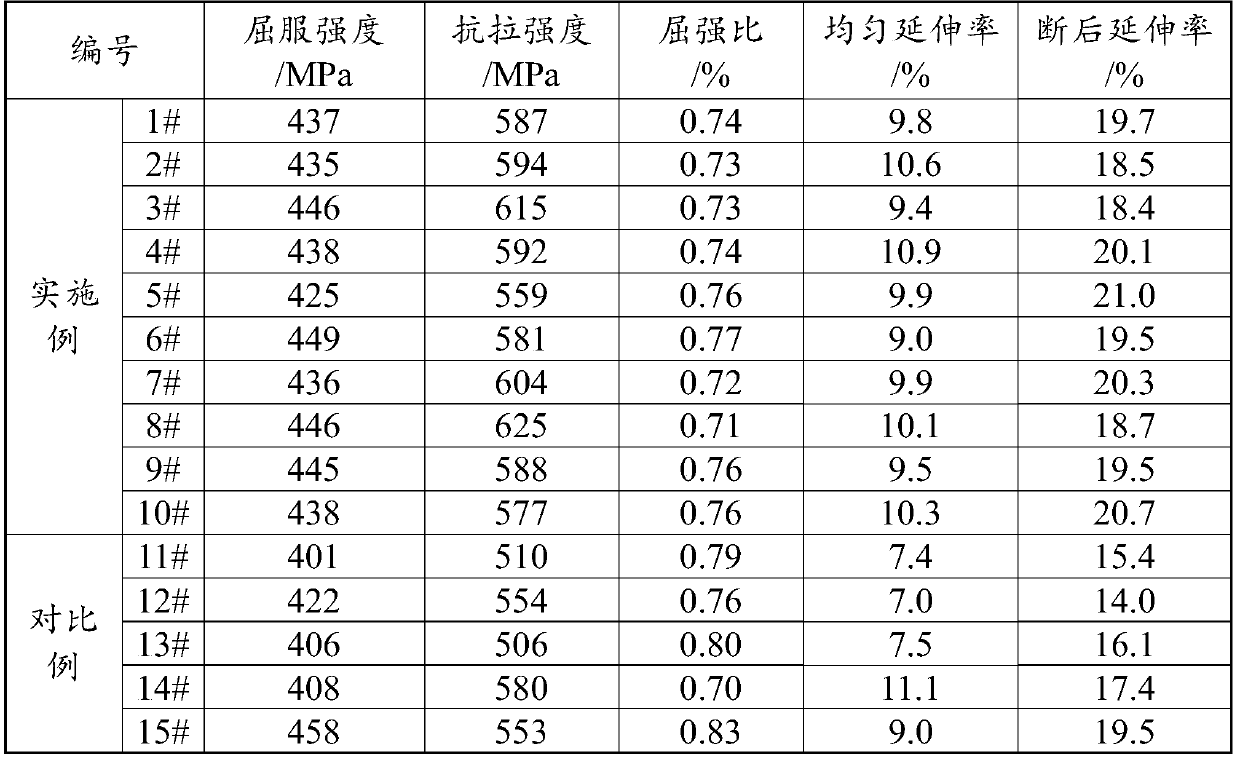

[0024] In the following, examples 1-10 using the 400MPa steel bar manufacturing technology of the present invention and comparative examples 11-15 of the conventional process route will be compared and implemented.

[0025] Examples 1-10 and Comparative Examples 11-15 all adopt the technological route of converter smelting-billet continuous casting-steel bar rolling-cooling bed cooling.

[0026] In Examples 1-10, in the manufacturing method of 400MPa grade steel bars, 0.3kg / t silicon manganese nitride is added to the ladle when the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com