A kind of substrate coated with composite film and its preparation method and application

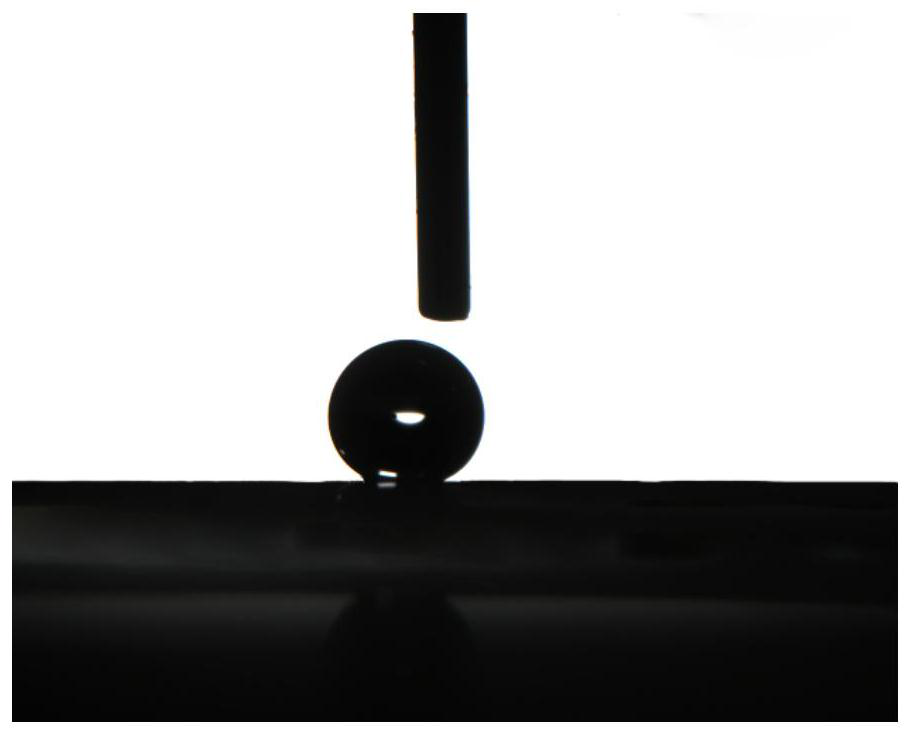

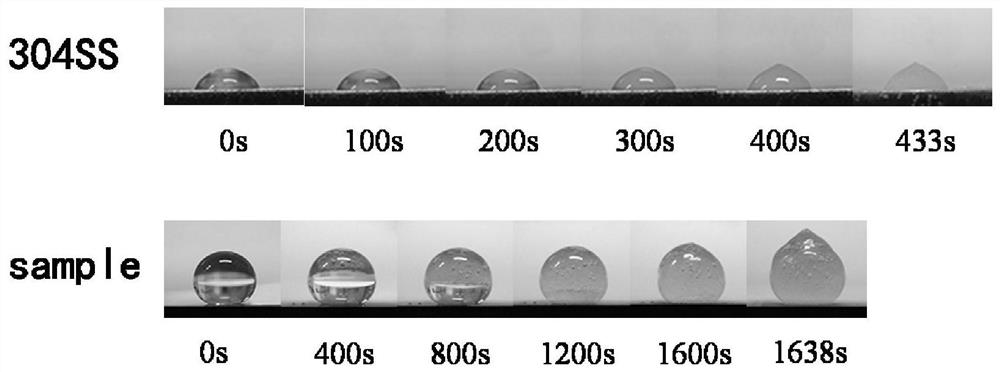

A composite film and surface coating technology, applied in the field of hydrogen energy, can solve the problems of gas transmission battery self-start failure, poor conductivity passivation film, bipolar plate flow channel blockage, etc., to prolong the anti-icing time, and the method is simple , Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

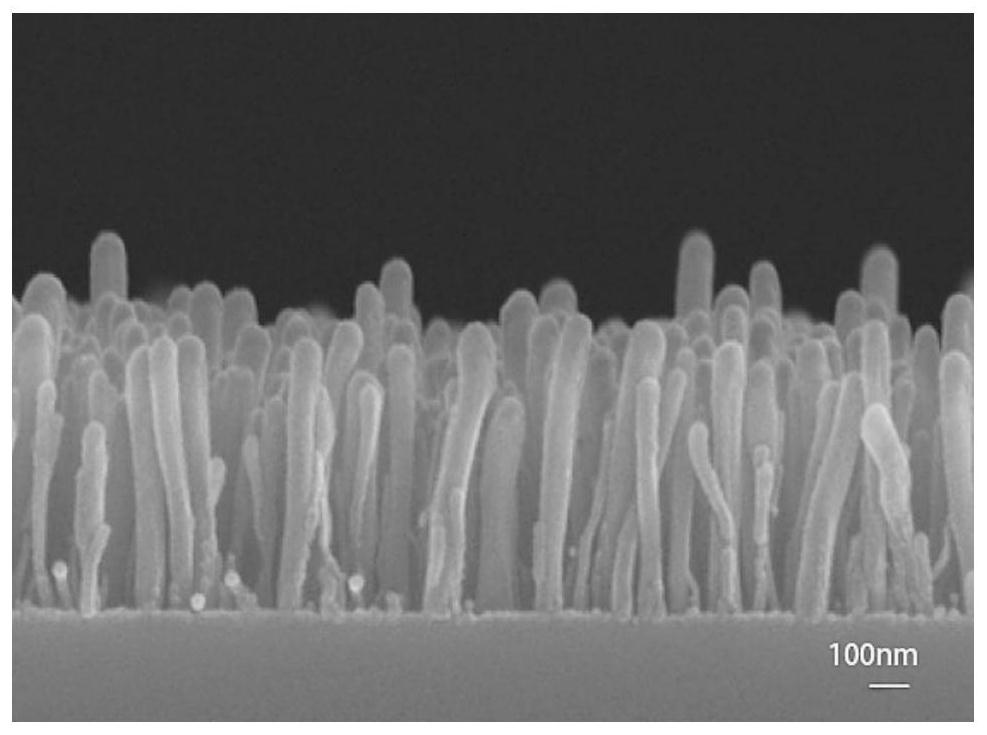

[0030] A method for preparing a substrate with a surface-coated diamond-like vertical carbon nanotube composite film, based on plasma-enhanced chemical vapor deposition equipment, said method comprising the steps of:

[0031] S1. Select 304 stainless steel as the substrate, polish it with sandpaper, and then ultrasonically pre-clean it with acetone, ethanol and deionized water for 10 minutes;

[0032] S2. Put the cleaned substrate into the reaction chamber of the plasma-enhanced chemical vapor deposition equipment, evacuate the reaction chamber to a pressure of 50 mT, and feed hydrogen gas with a flow rate of 10 sccm to maintain the pressure in the reaction chamber at 100 mT. Turn on the radio frequency, and the radio frequency The power is 200W, generating hydrogen plasma to clean the surface of the substrate, and the cleaning time is 15min;

[0033] S3. Turn off the radio frequency after cleaning the substrate, maintain the flow rate of hydrogen gas at 10 sccm, and raise the...

Embodiment 2

[0040] A method for preparing a substrate with a surface-coated diamond-like vertical carbon nanotube composite film, based on plasma-enhanced chemical vapor deposition equipment, said method comprising the steps of:

[0041] S1. Select 304 stainless steel as the substrate, polish it with sandpaper, and then ultrasonically pre-clean it with acetone, ethanol and deionized water for 8 minutes;

[0042] S2. Put the cleaned substrate into the reaction chamber of the plasma-enhanced chemical vapor deposition equipment, evacuate the reaction chamber to a pressure of 80mT, and feed hydrogen gas with a flow rate of 10sccm to maintain the pressure in the reaction chamber at 100mT. Turn on the radio frequency, radio frequency The power is 180W, and the hydrogen plasma is generated to clean the surface of the substrate again, and the cleaning time is 10 minutes;

[0043] S3. Turn off the radio frequency after the substrate cleaning is completed, maintain the flow rate of hydrogen gas at ...

Embodiment 3

[0047] A method for preparing a substrate with a surface-coated diamond-like vertical carbon nanotube composite film, based on plasma-enhanced chemical vapor deposition equipment, said method comprising the steps of:

[0048] S1. Select 304 stainless steel as the substrate, polish it with sandpaper, and then ultrasonically pre-clean it with acetone, ethanol and deionized water for 15 minutes;

[0049] S2. Put the cleaned substrate into the reaction chamber of the plasma-enhanced chemical vapor deposition equipment, evacuate the reaction chamber to a pressure of 100mT, feed hydrogen gas with a flow rate of 10 sccm, turn on the radio frequency, and the power of the radio frequency is 220W to generate hydrogen plasma Clean the substrate surface again for 10 minutes;

[0050] S3. After cleaning the substrate, turn off the radio frequency, maintain the flow rate of hydrogen gas at 10 sccm, and at the same time raise the temperature to the growth temperature of diamond-like carbon a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com