Grease composition and whipped non-dairy cream containing grease composition

An oil and fat composition and oil technology, which are applied in the production/processing of edible oil/fat, edible oil/fat, edible oil/fat composition, etc., can solve the problems of low pasting rate, long pasting time, and poor shape retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

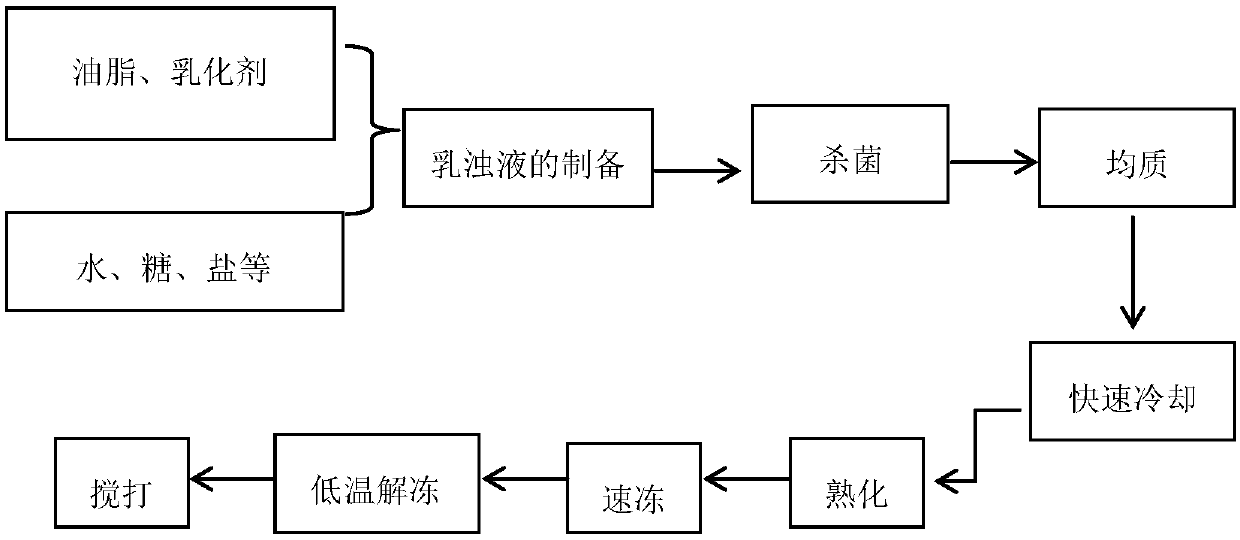

[0061] The preparation of the emulsion usually includes the preparation of the water phase and the oil phase, and the steps of mixing, quenching, aging and the like of the oil phase and the water phase. Usually, the preparation of the oil phase includes heating the oil component to eg 50-70°C, then adding an appropriate amount of emulsifier and stirring to dissolve the emulsifier in the oil. The preparation of the water phase includes dissolving the degreasing agent, the remaining emulsifier and other ingredients in water, and stirring evenly. The water is usually heated to 60 to 75°C.

[0062] When mixing, slowly pour the oil phase into the water phase and stir rapidly at 60 to 70°C to fully mix the two. Water lost during mixing can be replenished. After mixing, the resulting emulsion can be sterilized, for example, heated at 65 to 80° C. for 5 to 10 minutes for pasteurization. Water can be added appropriately during sterilization. The obtained emulsion can be homogenized...

Embodiment 1

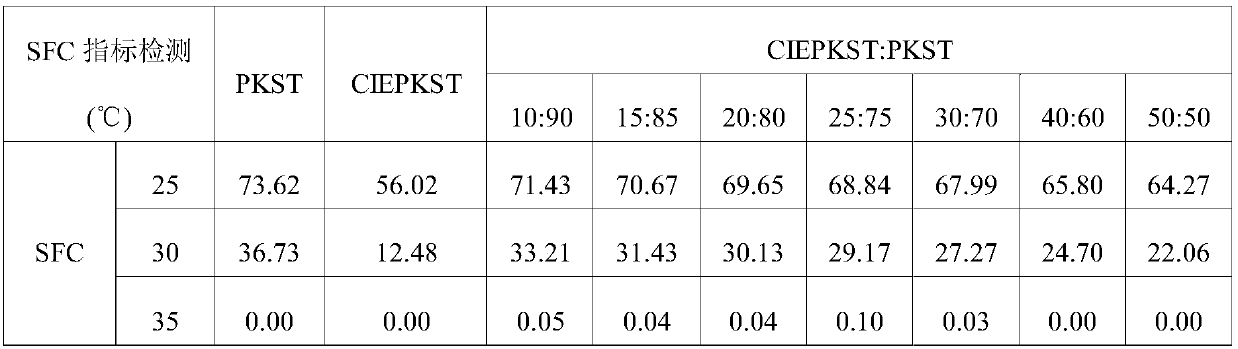

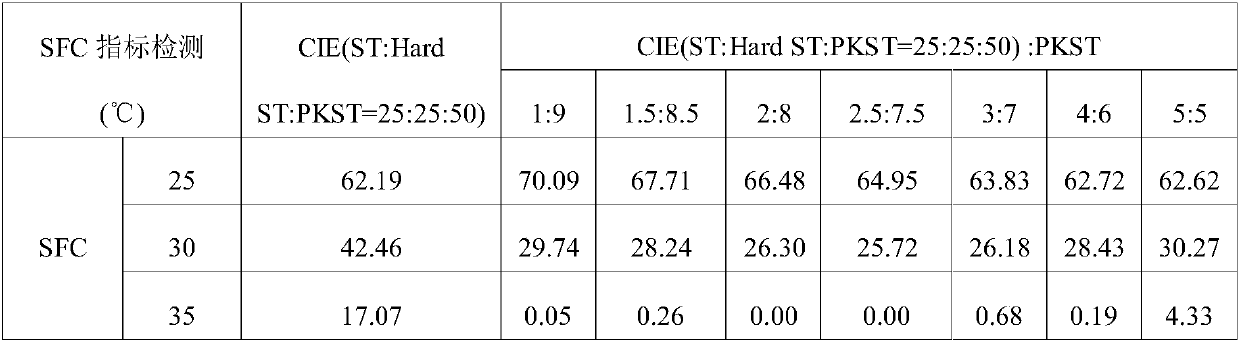

[0089] Weigh raw oils and fats and add them into a three-neck bottle, said raw oils and fats are: 500g of PKST; 125g of ST, 125g of Hard ST and 250g of PKST; or 125g of ST and 375g of PKST. Dehydration at 105°C for 30min under reduced pressure (pressure<100Pa); add 0.4% (calculated based on the mass of mixed oil) sodium methoxide as a catalyst, and react at 105°C under reduced pressure (pressure<100Pa) for 40min; Add citric acid (10% concentration, w / w) twice to terminate the reaction, wash with water until neutral; dehydrate at 105°C for 1-1.5 hours under reduced pressure (pressure <100Pa), add activated clay with an oil weight of 1.5% , continue to stir for 25 minutes to decolorize, then filter with suction at 70°C, and finally deodorize at 240°C under reduced pressure and nitrogen for 2 hours to obtain CIEPKST (ie, the transesterification product of PKST), CIE (ST: Hard ST: PKST = 25:25 :50) (that is, the transesterification product of ST, Hard ST and PKST in the mass ratio...

Embodiment 2

[0110] The whipping cream was prepared according to the formula shown in Table 8.

[0111] Table 8

[0112] Ingredients

content(%)

raw material source

50-65

oil composition

18-35

The fat of embodiment one

Maltose syrup

8-20

Provided by Shengtai

White sugar

8-20

commercially available

Emulsifier:

sodium caseinate

0-2

provided by fonterra

Tween 60

0-2

Provided by Lonza

Mono, Diglycerides of Fatty Acids

0-2

Danisco offers

Span 60

0-2

Provided by Lonza

Thickener:

Hydroxypropylmethylcellulose

0-2

Dow offers

Colloids (xanthan gum, guar gum, etc.)

0-2

Danisco

sodium alginate

0-2

Danisco

Appropriate amount

0-2

Corondo

Salt

0-2

commercially available

total

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com