Pharmaceutical salt refining technology

A medicinal salt and process technology, applied in the field of medicinal salt refining technology, can solve problems such as increasing processing cost, and achieve the effect of avoiding cost pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

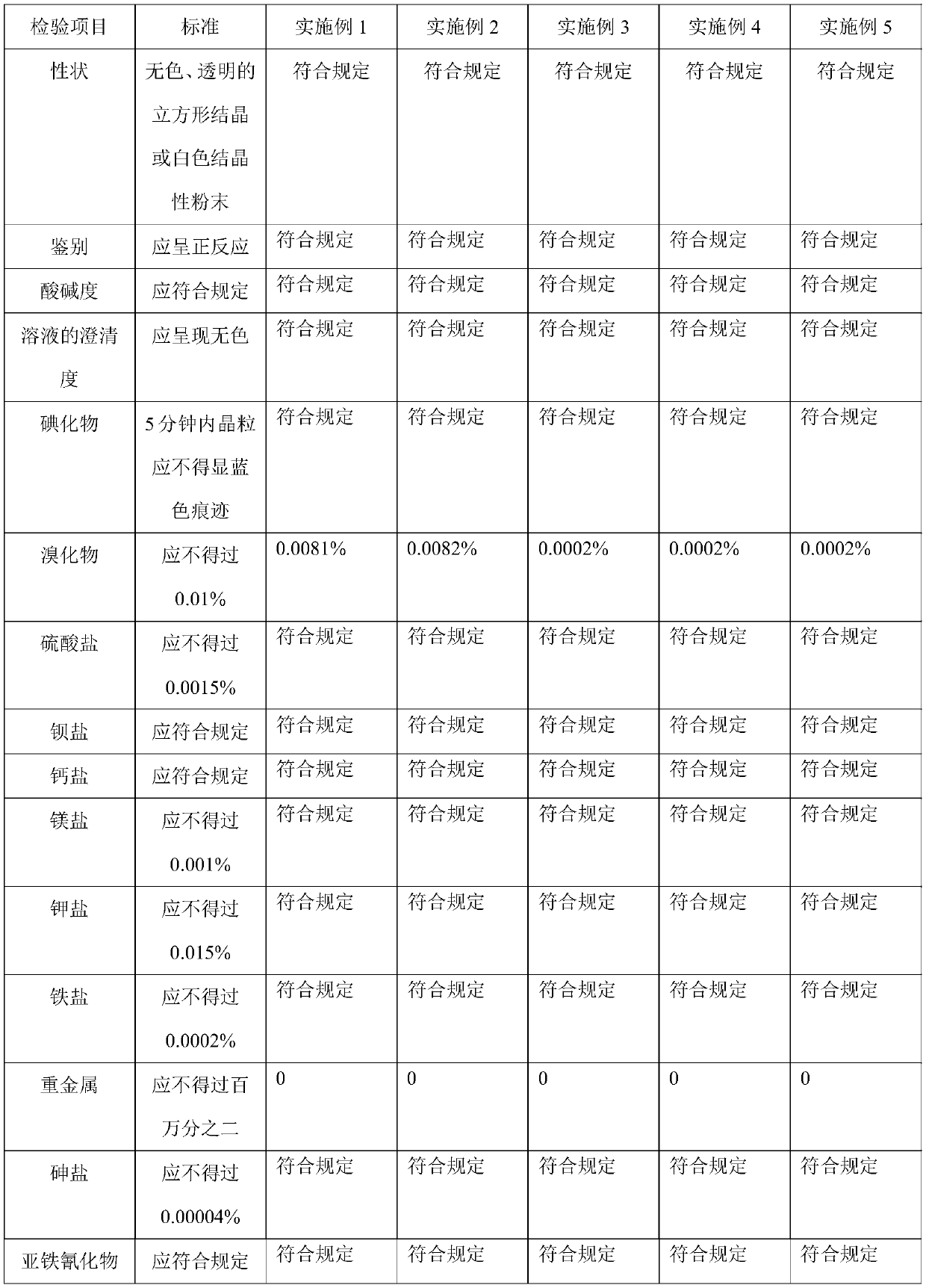

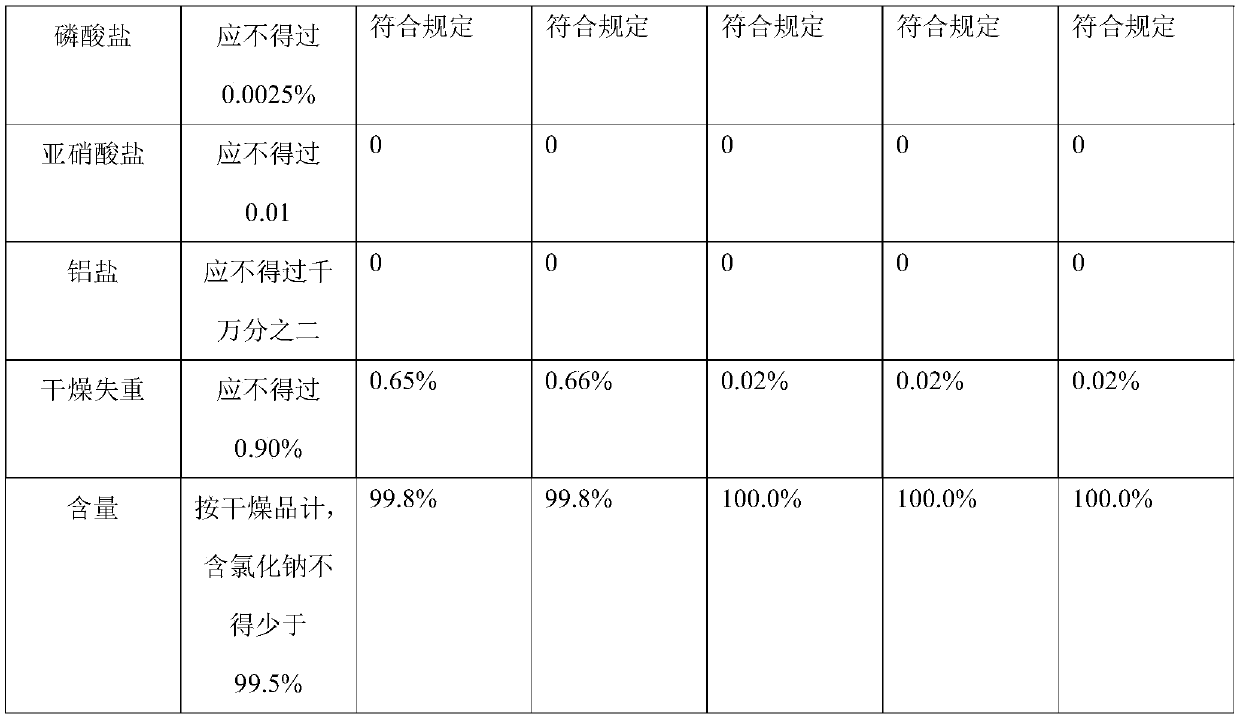

Embodiment 1

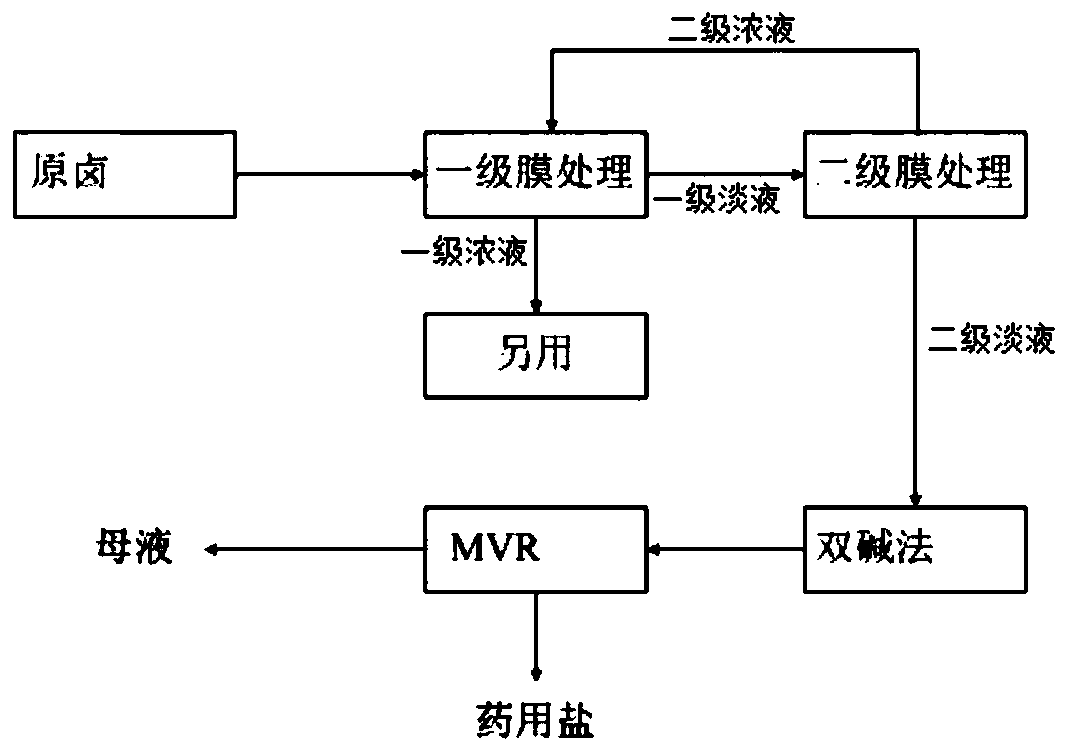

[0042] A medicinal salt refining process, the specific method is: after the natural brine is treated with a primary membrane and a secondary membrane, it is treated with a double alkali method, and finally evaporated and concentrated to obtain a refined pharmaceutical salt.

[0043] The natural brine is treated with the first-level membrane to obtain the first-level concentrated liquid and the first-level light liquid. The former is used separately, and the latter enters the second-level membrane for treatment to obtain the second-level concentrated liquid and the second-level light liquid. The former returns to the first-level membrane for treatment, and the latter Enter the double-alkali treatment step, and then obtain refined pharmaceutical salt through evaporation and concentration. "Other use" means that it can be used in other chemical fields to realize waste utilization.

[0044] The process parameters of the first-stage membrane treatment are: the recovery rate is 54%,...

Embodiment 2

[0051] A medicinal salt refining process, the specific method is: after the natural brine is treated with a primary membrane and a secondary membrane, it is treated with a double alkali method, and finally evaporated and concentrated to obtain a refined pharmaceutical salt.

[0052] The natural brine is treated with the first-level membrane to obtain the first-level concentrated liquid and the first-level light liquid. The former is used separately, and the latter enters the second-level membrane for treatment to obtain the second-level concentrated liquid and the second-level light liquid. The former returns to the first-level membrane for treatment, and the latter Enter the double-alkali treatment step, and then obtain refined pharmaceutical salt through evaporation and concentration. "Other use" means that it can be used in other chemical fields to realize waste utilization.

[0053] The process parameters of the first-stage membrane treatment are: the recovery rate is 70%,...

Embodiment 3

[0060] A medicinal salt refining process, the specific method is: after the natural brine is treated with a primary membrane and a secondary membrane, it is treated with a double alkali method, and finally evaporated and concentrated to obtain a refined pharmaceutical salt.

[0061] Add 2ppm of additives to natural brine and then perform primary membrane treatment and secondary membrane treatment. , Hypromellose acetate succinate mixed at a mass ratio of 1:0.3:0.05:3:0.8. The preparation method of the additive is as follows: acrylic acid-acrylic acid ester-sulfonate terpolymer, ethanolamine and triethylenetetramine are stirred and mixed evenly, and polyglycerol fatty acid ester, hypromellose acetate succinic acid are added while stirring. Esters, ultrasonic vibration treatment for 40 minutes.

[0062] The natural brine is treated with the first-level membrane to obtain the first-level concentrated liquid and the first-level light liquid. The former is used separately, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com