Preparation method of 4,4'-(hexafluoroisopropylene)diphthalic anhydride

A technology of hexafluoroisopropene and diphthalic anhydride, which is applied in the field of material preparation, can solve the problems of high energy consumption in the reaction process, difficult separation of metal ions, cumbersome reaction steps, etc., to avoid the use of metal ions, fewer synthesis steps, and high selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

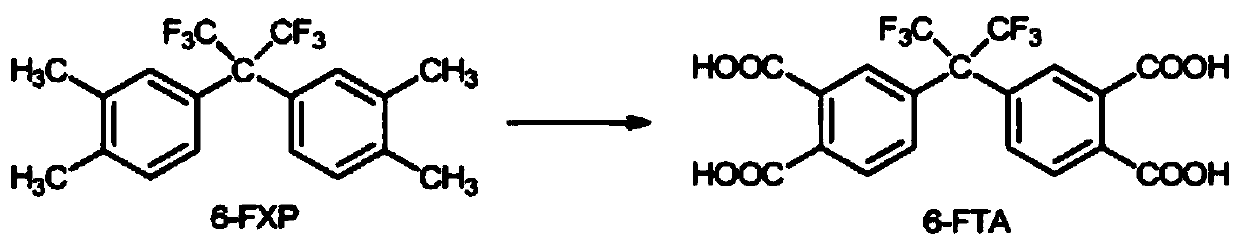

[0040] A kind of preparation method of 4,4'-(hexafluoroisopropylene) diphthalic anhydride, it comprises the following steps:

[0041] First, 100g of granular 4,4'-(hexafluoroisopropenyl)-di-o-xylene (6-FXP) is pulverized and dispersed with 20g of water in a wet nano-grinding disperser; the power of the nano-wet pulverizer is 12KW , The fineness of the crushed material is about 80nm.

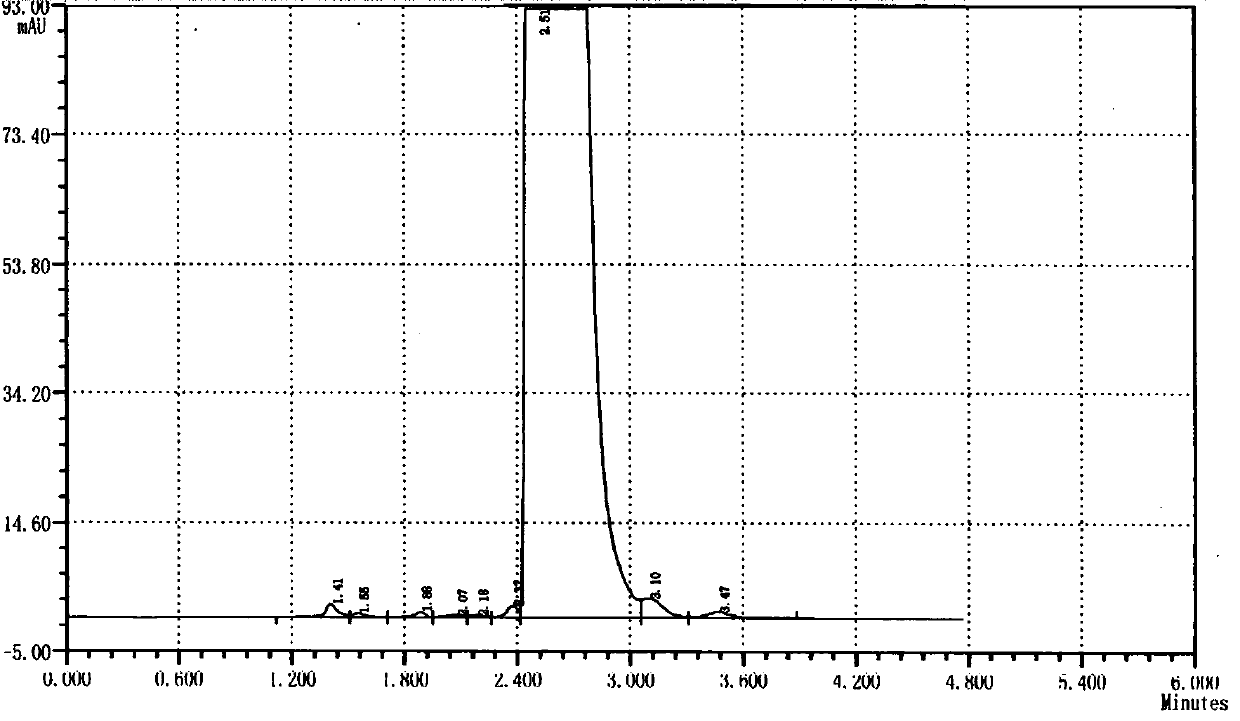

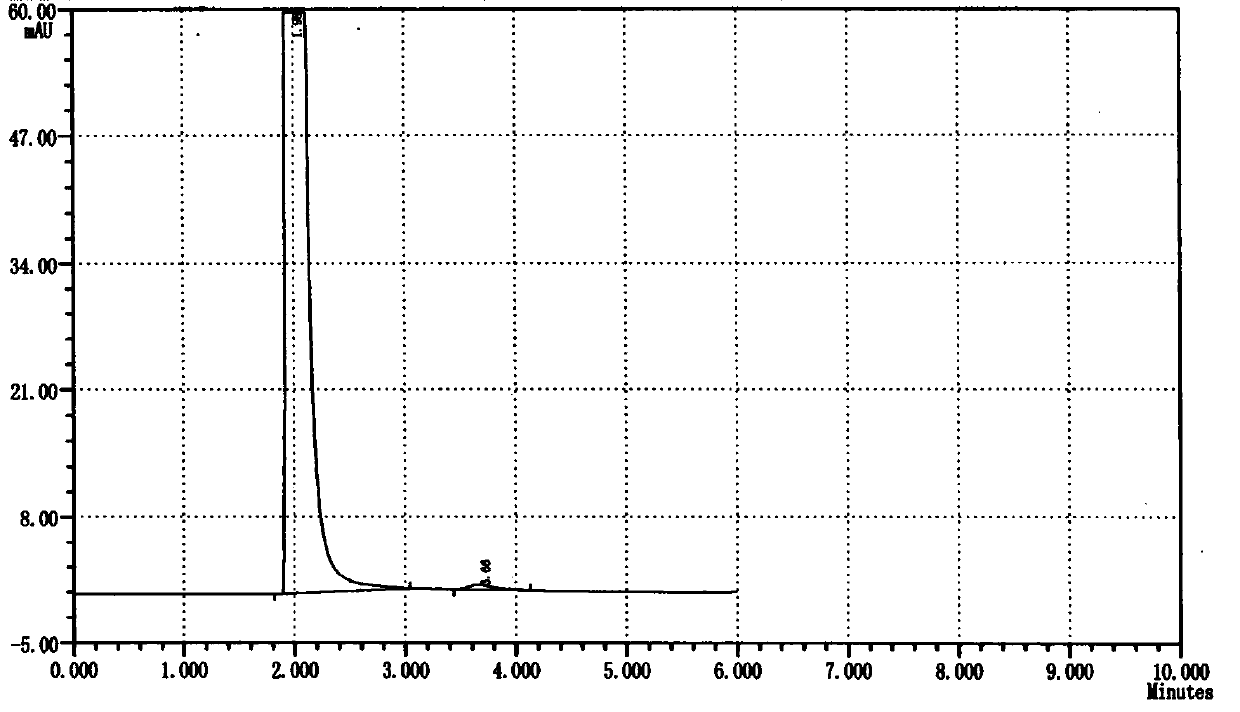

[0042] Take 100g of dispersed nano-scale 4,4'-(hexafluoroisopropenyl)-di-o-xylene (6-FXP) and 120g of aqueous hydrogen peroxide solution with a mass concentration of 80% and add them into the photoreactor for uniform dispersion. Then 10°C, normal pressure, turn on 2Kw LED cold ultraviolet light with a wavelength of 380nm, and the ultraviolet light power ultraviolet light induces the light source to irradiate the reaction solution for 2 hours, then heat to 55°C for 4.2 hours, and then filter the reaction solution with a nano-membrane filter, the pore size of the nano-membrane filter is 12nm, afte...

Embodiment 2

[0047] A kind of preparation method of 4,4'-(hexafluoroisopropylene) diphthalic anhydride, it comprises the following steps:

[0048] First, 100 g of granular 4,4'-(hexafluoroisopropenyl)-di-o-xylene (6-FXP) was pulverized and dispersed with 200 g of water in a wet nano-grinding disperser. The power of the nano wet pulverizer is 12KW, and the fineness of the pulverized material is about 80nm.

[0049] Take 100g of dispersed nano-scale 4,4'-(hexafluoroisopropenyl)-di-o-xylene (6-FXP) and 48g of aqueous hydrogen peroxide solution with a mass concentration of 80% and add them to the photoreactor for uniform dispersion. Then -6°C, normal pressure, turn on 2Kw LED cold ultraviolet light with a wavelength of 320nm, and the ultraviolet light power ultraviolet light induces the light source to irradiate the reaction solution for 2.5h, and then heat to 50°C for 12h oxidation reaction, and the reaction solution is covered with a nano-film Filtrate through a filter, and after cooling to...

Embodiment 3

[0052] A kind of preparation method of 4,4'-(hexafluoroisopropylene) diphthalic anhydride, it comprises the following steps:

[0053] First, 100 g of granular 4,4'-(hexafluoroisopropenyl)-di-o-xylene (6-FXP) was pulverized and dispersed with 200 g of water in a wet nano-grinding disperser. The power of the nano wet pulverizer is 15KW, and the fineness of the pulverized material is about 80nm.

[0054] Take 100g of dispersed nano-scale 4,4'-(hexafluoroisopropenyl)-di-o-xylene (6-FXP) and 77g of 50% aqueous hydrogen peroxide solution in a photoreactor for uniform dispersion, Then at 32°C and normal pressure, turn on 15Kw LED cold ultraviolet light with a wavelength of 400nm, and the ultraviolet light power ultraviolet light induces the light source to irradiate the reaction solution for 1.2h, and then heats to 60°C for 2.4h oxidation reaction, and then the reaction solution is covered with a nano-film Filtrate through a filter, and after cooling to room temperature, obtain 6-FT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com