Production method of high-strength steel

A production method and high-strength steel technology, applied in the field of steel rolling, can solve problems such as increased iron sheet adhesion, cold-rolled color difference defects, customer troubles, etc., to achieve the effect of reducing the incidence of color difference defects and improving the surface quality of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

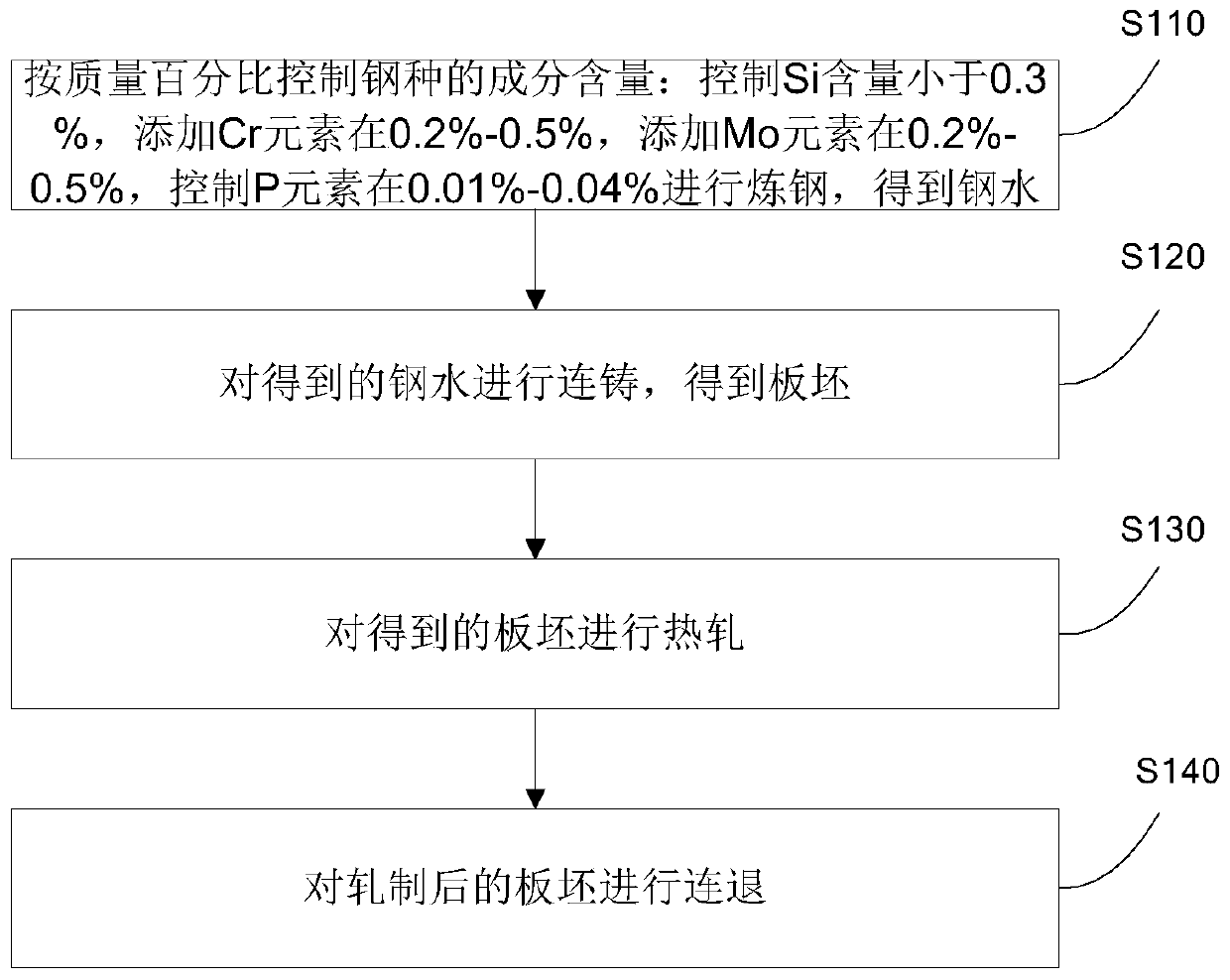

Method used

Image

Examples

Embodiment 1

[0053] The steel composition design is shown in Table 1 below. The composition design only adopts the Si-Cr-Mo composition system. The Si element content is as high as 0.2%, the Cr element is controlled at 0.5%, and the Mo element is controlled at 0.2%. At the same time, an appropriate amount of P element is added to 0.03 %, the formulated hot rolling process route is shown in Table 2 below. The temperature of the hot rolling out of the furnace is controlled at 1180°C, and the time in the furnace is controlled at 170min. The finish rolling adopts double-pass descaling, the finish rolling inlet temperature is 1000°C, and the cooling water ratio between the three stands before the finish rolling is 50%. The opening ratio of roll gap water reaches 80%. At the same time, the rolling lubrication process was put into use, and the final rolling temperature was controlled at 910°C. The coiling adopts the front-end intensive cooling mode, the coiling temperature is controlled at 580°C...

Embodiment 2

[0059] The steel composition design is shown in Table 3 below. The composition design only adopts the Si-Cr-Mo composition system. The Si element content is as high as 0.2%, the Cr element is controlled at 0.2%, and the Mo element is controlled at 0.5%. At the same time, an appropriate amount of P element is added to 0.02 %, the formulated hot rolling process route is shown in Table 4 below. The temperature of the hot rolling out of the furnace is controlled at 1190°C, and the time in the furnace is controlled at 180min. The finishing rolling adopts double-pass descaling, the finishing rolling inlet temperature is 990°C, and the cooling water ratio between the three stands before the finishing rolling is 50%. The opening ratio of roll gap water reaches 80%. At the same time, the rolling lubrication process was put into use, and the final rolling temperature was controlled at 900°C. The coiling adopts the front-end ultra-fast cooling mode, the coiling temperature is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com