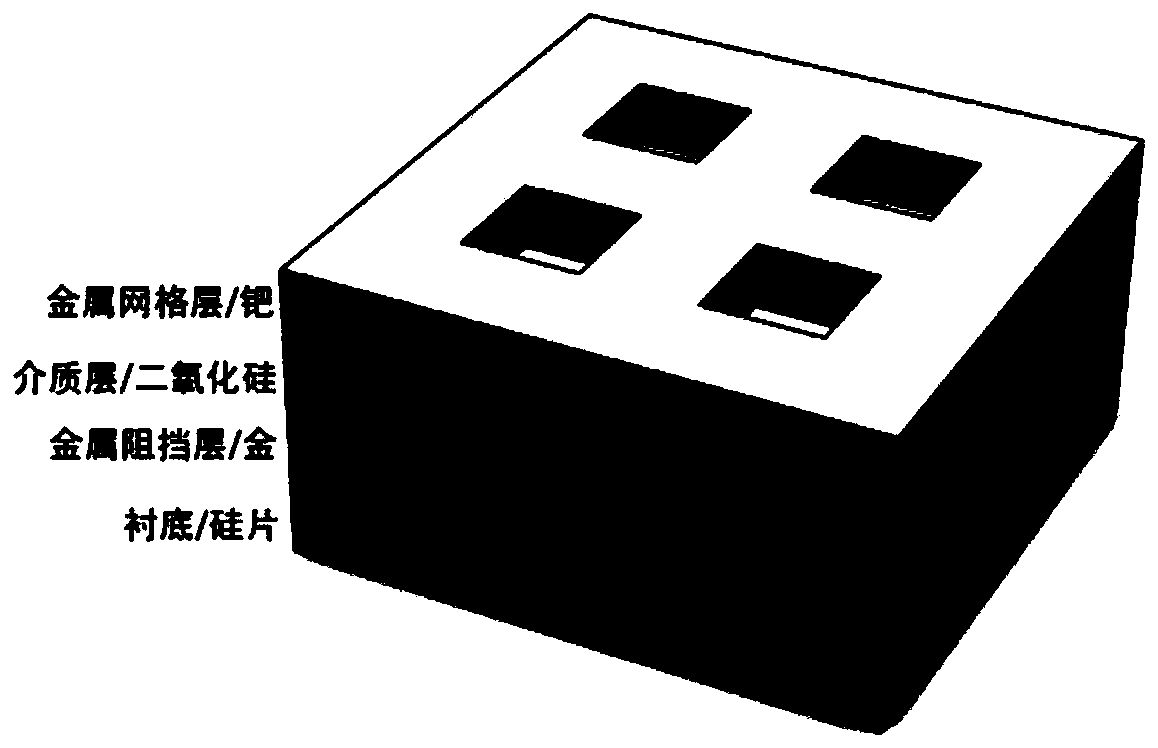

Two-dimensional optical grating-based light absorber and manufacturing method thereof

A two-dimensional grating and manufacturing method technology, applied in optics, instruments, optical components, etc., can solve problems such as difficult graphics, and achieve the effects of suppressing sensitivity, high-efficiency absorption, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A: Place silicon wafers in acetone, absolute ethanol (wt99.99, AR) and deionized water for ultrasonic cleaning for 30 minutes, blow dry with a nitrogen gun, then dry with a drying table higher than 100°C, and cool for 3 minutes;

[0028] B: Use DC sputtering process to sputter a layer of Cr on the silicon wafer as the connecting metal, pump for 6 hours, and the vacuum degree is lower than 5×10 -4 Pa, the sputtering power is 100w, the sputtering pressure is 0.5Pa, the sputtering time is 4s, and then a layer of Au is sputtered by DC sputtering process, and the vacuum is lower than 5×10 -4 Pa, the sputtering power is 100w, the sputtering pressure is 0.5Pa, the sputtering time is 25s, and then a layer of SiO is sputtered by radio frequency sputtering process 2 , pumping for 6h, the vacuum degree is lower than 5×10 -4 Pa, the RF sputtering power is 100w, the sputtering pressure is 0.5Pa, and the sputtering time is 15s;

[0029]C: A layer of MMA is spin-coated on the sputte...

Embodiment 2

[0035] A: Place silicon wafers in acetone, absolute ethanol (wt99.99, AR) and deionized water for ultrasonic cleaning for 30 minutes, blow dry with a nitrogen gun, then dry with a drying table higher than 100°C, and cool for 3 minutes;

[0036] B: Use DC sputtering process to sputter a layer of Cr on the silicon wafer as the connecting metal, pump for 6 hours, and the vacuum degree is lower than 5×10 -4 Pa, the sputtering power is 100w, the sputtering pressure is 0.5Pa, the sputtering time is 4s, and then a layer of Au is sputtered by DC sputtering process, and the vacuum is lower than 5×10 -4 Pa, the sputtering power is 100w, the sputtering pressure is 0.5Pa, the sputtering time is 25s, and then a layer of SiO is sputtered by radio frequency sputtering process 2 , pumping for 6h, the vacuum degree is lower than 5×10 -4 Pa, the RF sputtering power is 100w, the sputtering pressure is 0.5Pa, and the sputtering time is 15s;

[0037] C: A layer of MMA is spin-coated on the sputt...

Embodiment 3

[0043] A: Place silicon wafers in acetone, absolute ethanol (wt99.99, AR) and deionized water for ultrasonic cleaning for 30 minutes, blow dry with a nitrogen gun, then dry with a drying table higher than 100°C, and cool for 3 minutes;

[0044] B: Use DC sputtering process to sputter a layer of Cr on the silicon wafer as the connecting metal, pump for 6 hours, and the vacuum degree is lower than 5×10 -4 Pa, the sputtering power is 100w, the sputtering pressure is 0.5Pa, the sputtering time is 4s, and then a layer of Au is sputtered by DC sputtering process, and the vacuum is lower than 5×10 -4 Pa, the sputtering power is 100w, the sputtering pressure is 0.5Pa, the sputtering time is 25s, and then a layer of SiO is sputtered by radio frequency sputtering process 2 , pumping for 6h, the vacuum degree is lower than 5×10 -4 Pa, the RF sputtering power is 100w, the sputtering pressure is 0.5Pa, and the sputtering time is 15s;

[0045] C: A layer of MMA is spin-coated on the sputt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com