Electronic method and device fo r drawing wire of elastic alloy

A technology of elastic alloy and alloy wire, which is applied in the direction of metal wire drawing, metal drawing forming tools, metal processing equipment, etc., can solve the problems of uneven structure and wire diameter, increased internal friction of alloy, high degree of texture, etc., to achieve Improve the uniformity and stability, improve the comprehensive mechanical properties, and improve the effect of plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

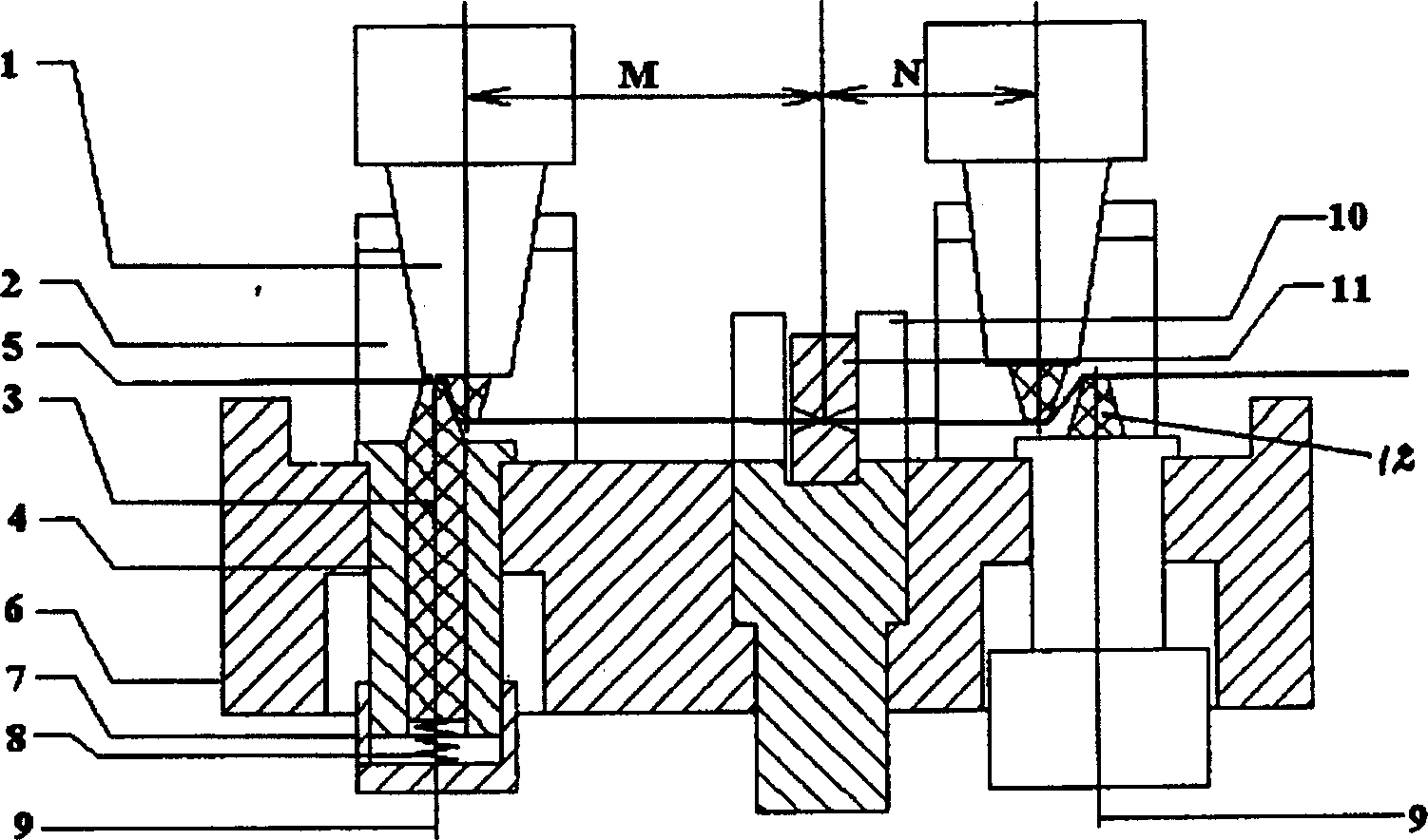

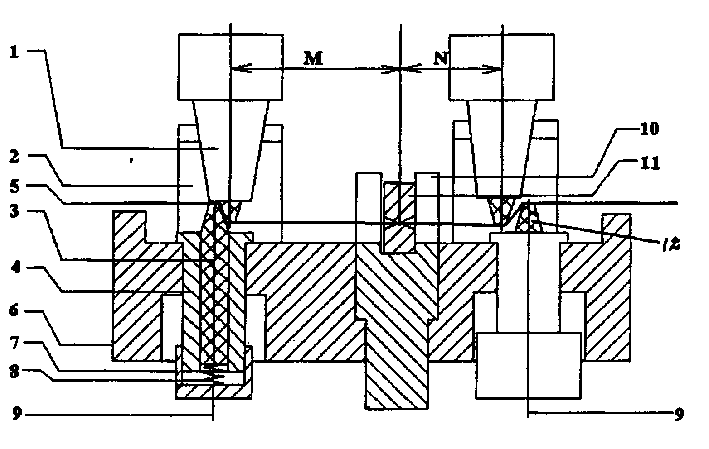

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: 3J53 alloy electronic wire drawing The electronic wire drawing process parameters that can be used for drawing 3J53 alloy wire from φ2.3mm to φ0.66mm are:

[0029] (1) Current density: j=Imax / F=370~1500A / mm 2

[0030] (2) Working voltage: 250V

[0031] (3) Current pulse width tp=80~100μs

[0032] (4) Current pulse frequency f=50~500Hz

[0033] The lowest drawing speed of the alloy is 0.1m / s. Shrinkage rate (deformation rate) ε = 1-(d / d 0 ) 2 = 90%. Compared with traditional wire drawing, the deformation of electronic wire drawing increases, and the drawing force decreases by 30-40%. The intermediate annealing is canceled, and the surface quality is significantly improved (no cracks, high finish).

Embodiment 2

[0034] Embodiment 2: 317L steel wire electronic wire drawing

[0035] 317L steel wire drawn from φ1.60mm to φ0.12 can adopt the electronic wire drawing process parameters as follows:

[0036] (1) Current density: j=Imax / F=500~2000A / mm 2

[0037](2) Working voltage: 250V

[0038] (3) Current pulse width: tp=80~100μs

[0039] (4) Current pulse frequency: f=50~900Hz

[0040] The drawing speed of steel wire is 0.1m / s. Shrinkage rate (deformation degree) ε = 1-(d / d 0 ) 2 = 99.4%. Compared with traditional wire drawing, the deformation of electronic wire drawing is greatly increased, and the wire drawing force is reduced by 30-40%. The strength of the wire is reduced by 10%, the intermediate annealing (2-3 times) is completely canceled, and the surface quality is greatly improved.

Embodiment 3

[0041] Example 3: Cr17Ni6Mn3 steel wire electronic wire drawing

[0042] Cr17Ni6Mn3 steel wire drawn from φ2.00mm to φ0.226 can adopt electronic wire drawing process parameters as follows:

[0043] (1) Current density: j=Imax / F=350~1500A / mm 2

[0044] (2) Working voltage: 250V

[0045] (3) Current pulse width tp=80~100μs

[0046] (4) Current pulse frequency f=50~600Hz

[0047] The drawing speed of steel is 0.1-1m / s. Shrinkage rate (deformation degree) ε = 1-(d / d 0 ) 2 = 98.2%. Compared with traditional wire drawing, the deformation of electronic wire drawing increases, and the drawing force decreases by 20-40%. The internal stress in the wire is reduced by 5-6%, the strength is reduced by ~10%, and the surface quality is obviously improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com