Process for preparing rubidium-doped titanium dioxide photocatalytic material by virtue of spray drying method

A technology of photocatalytic material and spray drying method, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst activation/preparation, etc. Coarse particle size distribution of colloidal particles, high cost of metal ion doping, etc., to achieve the effect of improving photocatalytic efficiency, expanding the range of photoresponse, and improving quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

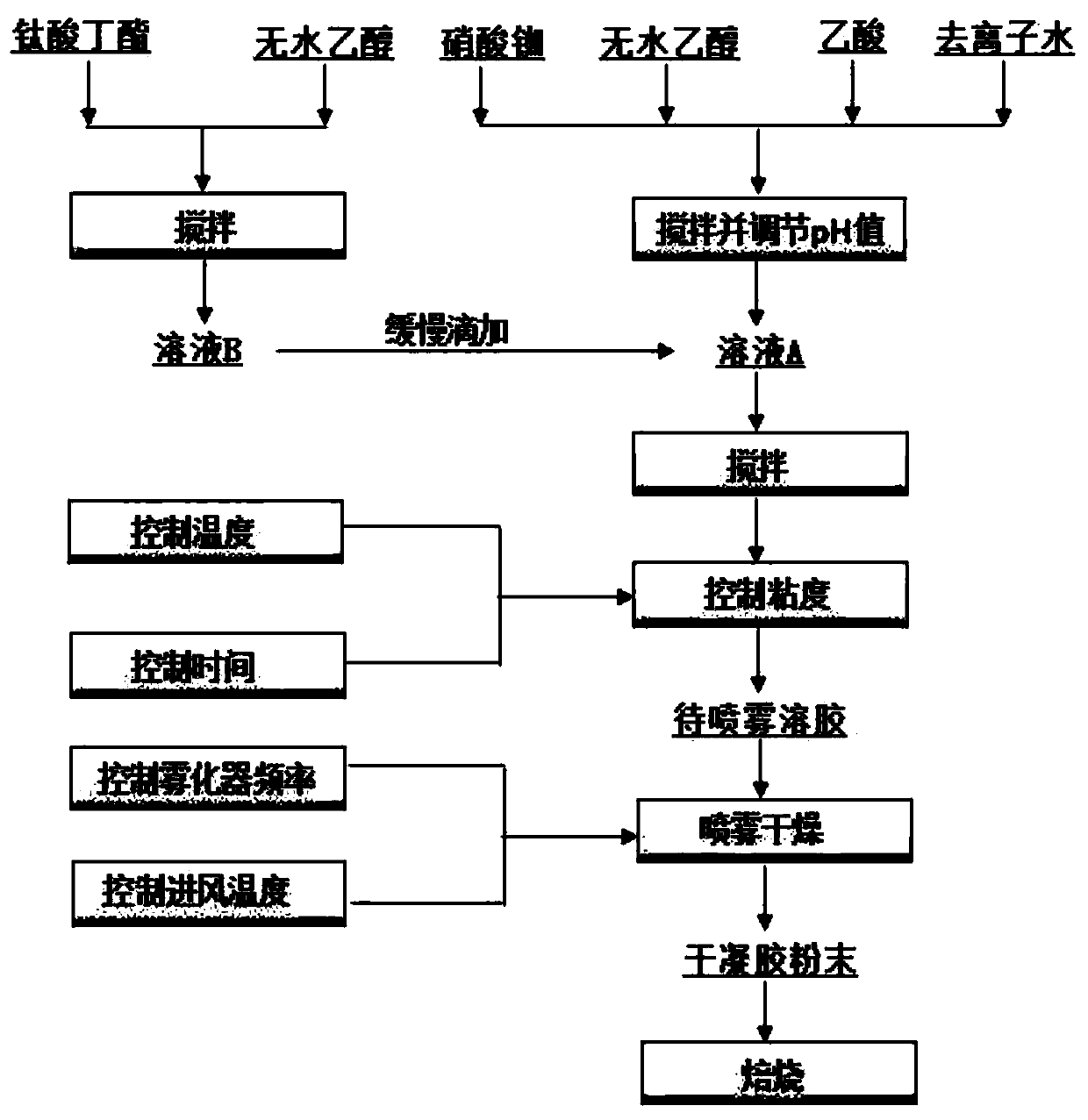

[0039] Such as figure 1 As shown, the specific operation steps of preparing rubidium-doped titanium dioxide photocatalytic material by spray drying method are as follows:

[0040] (1) Prepare solution A

[0041] Use deionized water to prepare a rubidium nitrate solution with a concentration of 0.01mol / L, add absolute ethanol and acetic acid, the volume ratio of the solution to absolute ethanol is 2:7, the volume ratio of acetic acid to absolute ethanol is 1:7, add nitric acid to adjust After the pH is 1.8, stir for 20 min at a stirring speed of 250 rpm to obtain solution A.

[0042] (2) Prepare solution B and prepare sol

[0043] Butyl titanate was added in a molar ratio of 500:1 to rubidium nitrate. Mix absolute ethanol with a volume ratio of 2:7 and butyl titanate, and stir them evenly to form solution B. The solution A was stirred at a stirring speed of 650rmp, and at the same time, the solution B was added into the solution A at a speed of 5mL / min to form a sol.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com