A kind of purification separation method of sucrose fatty acid ester

A technology of sucrose fatty acid ester and separation method, which is applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of causing environmental pressure and increasing solid waste, so as to reduce environmental pressure and facilitate industrial production , The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

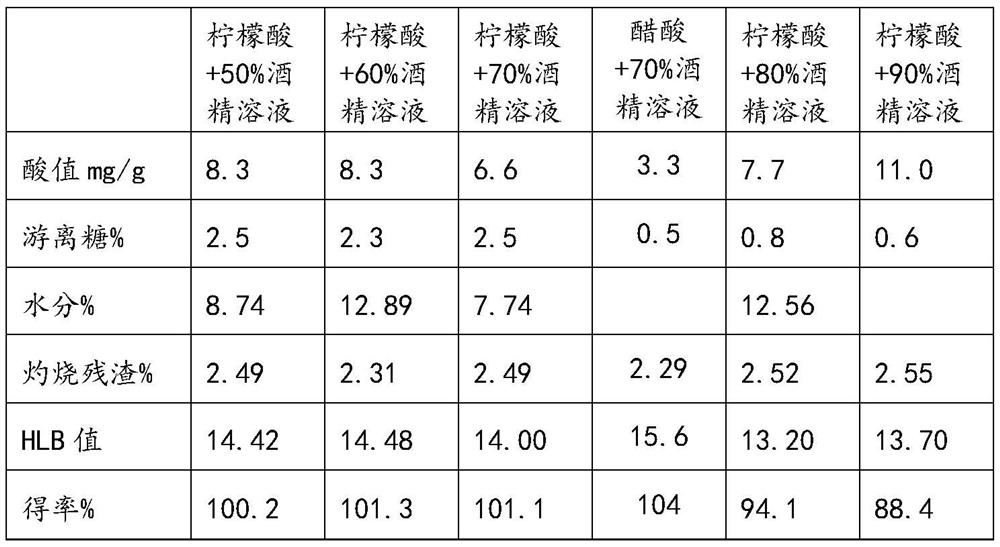

Examples

Embodiment 1

[0032] Primary extraction of crude sucrose fatty acid ester: Weigh about 20 g crude sucrose fatty acid ester (accurate to 0.0001 g), place it in a 250ml beaker, add 100ml of 70% alcohol solution (V / V), heat and stir in a water bath at 70°C Dissolve, adjust the pH between 2 and 4 with citric acid (adjust until obvious stratification can be seen), and discharge the water layer (lower layer);

[0033] Secondary extraction of crude sucrose fatty acid ester: add 12% NaCl+NaHCO to the upper organic phase 3 (1:1), stir with an electric stirrer for 15 minutes at 70 °C, cool to 5 °C to generate a coprecipitate containing sucrose fatty acid ester and salt, then add 20 ml of water, heat and dissolve in a 65 °C water bath, and discharge the water layer ( lower layer) to obtain sucrose fatty acid ester, air-dried at 35°C, and sealed for storage.

Embodiment 2

[0035] Primary extraction of crude sucrose fatty acid ester: Weigh about 20 g crude sucrose fatty acid ester (accurate to 0.0001 g), place it in a 250ml beaker, add 100ml of 70% alcohol solution (V / V), heat and stir in a water bath at 70°C Dissolve, adjust the pH between 2 and 4 with citric acid (adjust until obvious stratification can be seen), and discharge the water layer (lower layer);

[0036] Secondary extraction of crude sucrose fatty acid ester: add 13% NaCl+NaHCO to the upper organic phase 3 (1:1), stir with an electric stirrer for 15 minutes at 70 °C, cool to 5 °C to generate a coprecipitate containing sucrose fatty acid ester and salt, then add 20 ml of water, heat and dissolve in a 65 °C water bath, and discharge the water layer ( lower layer) to obtain sucrose fatty acid ester, air-dried at 35°C, and sealed for storage.

Embodiment 3

[0038] Primary extraction of crude sucrose fatty acid ester: Weigh about 20 g crude sucrose fatty acid ester (accurate to 0.0001 g), place it in a 250ml beaker, add 100ml of 70% alcohol solution (V / V), heat and stir in a water bath at 70°C Dissolve, adjust the pH between 2 and 4 with citric acid (adjust until obvious stratification can be seen), and discharge the water layer (lower layer);

[0039] Secondary extraction of crude sucrose fatty acid ester: add 14% NaCl+NaHCO to the upper organic phase 3 (1:1), stir with an electric stirrer for 15 minutes at 70 °C, cool to 5 °C to generate a coprecipitate containing sucrose fatty acid ester and salt, then add 20 ml of water, heat and dissolve in a 65 °C water bath, and discharge the water layer ( lower layer) to obtain sucrose fatty acid ester, air-dried at 35°C, and sealed for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com