Construction method of in-tube grouting, extrusion and expansion root-fixed pile

A construction method and a technology of grouting in pipes, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of reducing vertical bearing capacity, crushing of pile foundations, and consuming more concrete, etc., to improve the soil layer at pile ends Bearing capacity, improvement of pile tip bearing capacity, and wide range of soil applicability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

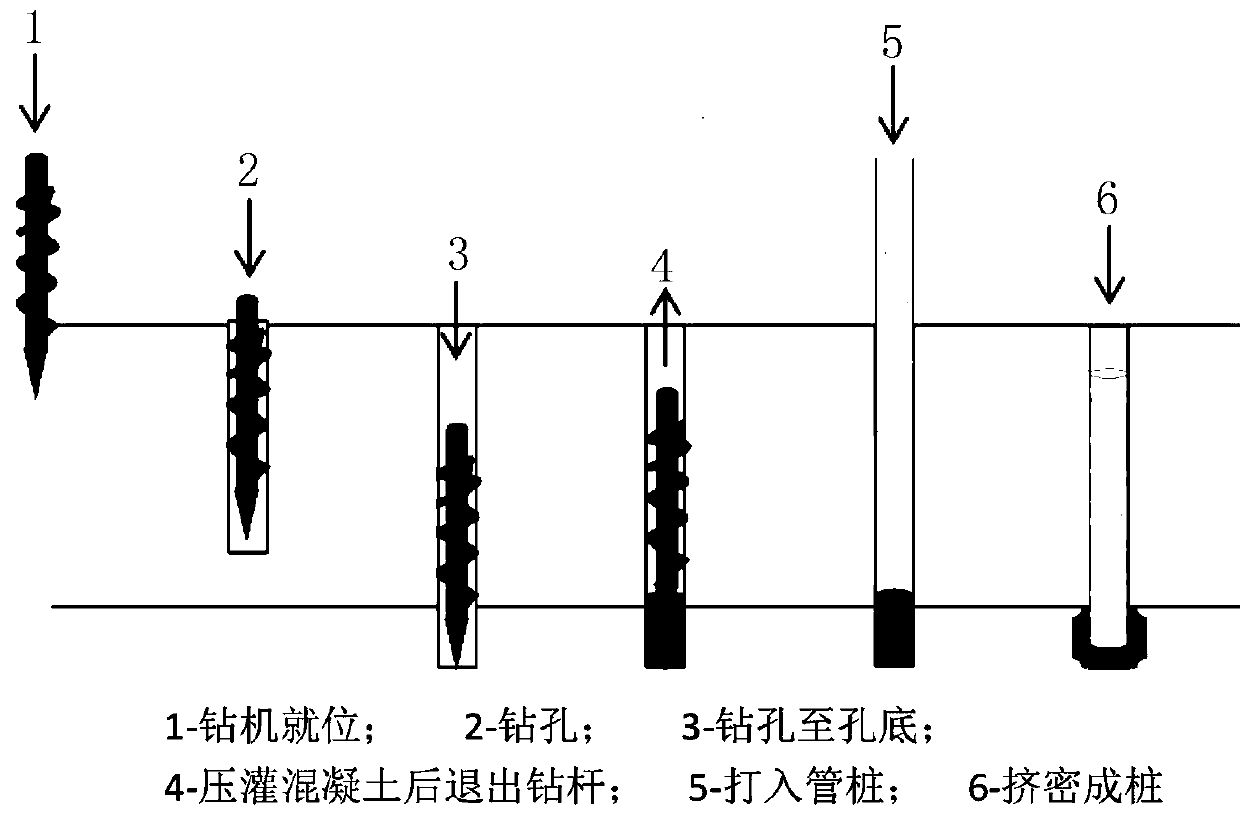

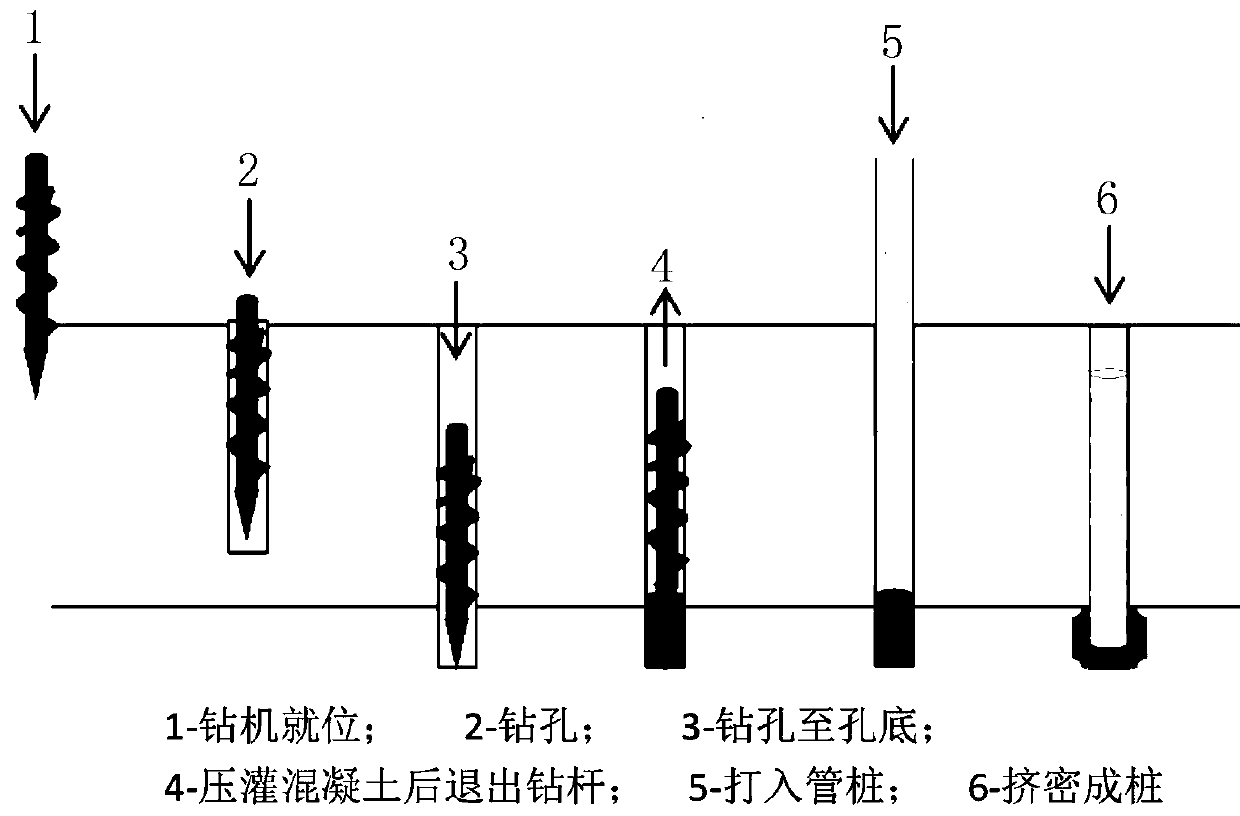

[0030] A construction method for grouting in pipes to squeeze and expand root-fixed piles, such as figure 1 shown, including the following steps:

[0031] (1) At the pile position, use an auger drill to take soil to form an approach hole with a diameter of 600mm and a depth of 12m;

[0032] (2) After the auger drill drills to the bottom elevation of the pilot hole, pump the grouting material into the pilot hole through the pipeline, and lift the drilling rig at the same time. The depth of the grouting material in the pilot hole is 0.3 times the depth of the pilot hole (that is, the The depth of the grouting material is 3.6m), the grouting material is cement mortar mixture, the cement mortar mixture is composed of the following raw materials: cement 15 wt%, sand 60 wt%, fly ash 5wt%, water 15 wt%, Additive 5 wt% (the additive is made by mixing water reducer and retarder at a mass ratio of 1:1); the strength of cement mortar mixture is not less than 15Mpa;

[0033] (3) Implant...

Embodiment 2

[0035] A construction method for grouting in pipes to squeeze and expand root-fixed piles, such as figure 1 shown, including the following steps:

[0036] (1) At the pile position, use an auger drill to take soil to form an approach hole with a diameter of 750mm and a depth of 16m;

[0037](2) After the auger drilling rig reaches the bottom elevation of the pilot hole, pump the grouting material into the pilot hole through the pipeline, and lift the drilling rig at the same time. The depth of the grouting material in the pilot hole is 0.5 times the depth of the pilot hole (that is, the The depth of the grouting material is 8m), the grouting material is cement mortar mixture, the cement mortar mixture is composed of the following raw materials: cement 12wt%, sand 65wt%, fly ash 5wt%, water 15wt%, water reducer 3wt%; the strength of the cement mortar mixture is not less than 15Mpa;

[0038] (3) Implant prefabricated piles into the lead holes, the prefabricated piles are PHC pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com