A kind of cable material containing dopo and crosslinked alkenyl polyaryletherketone and its preparation method

A technology of polyaryletherketone and alkenyl, applied in the field of preparation of polyaryletherketone containing DOPO and cross-linked alkenyl, which can solve the problems of many additives, complex preparation process requirements, and reduced reliability of ultra-thin-wall insulated cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

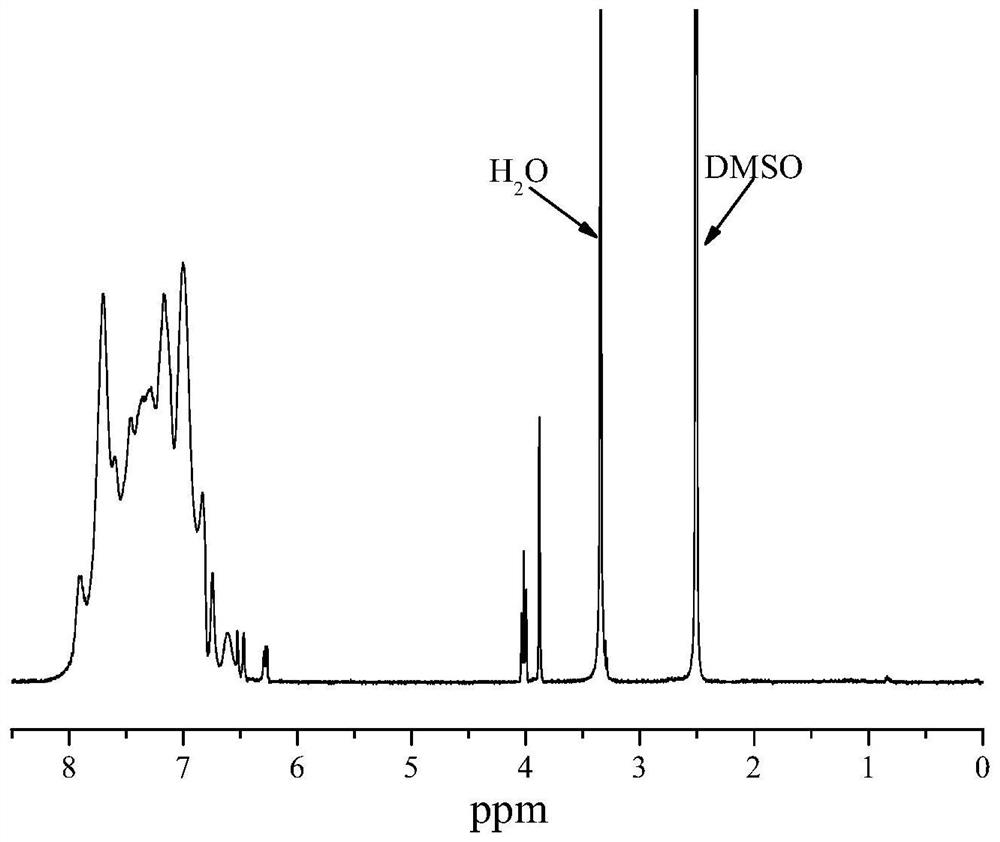

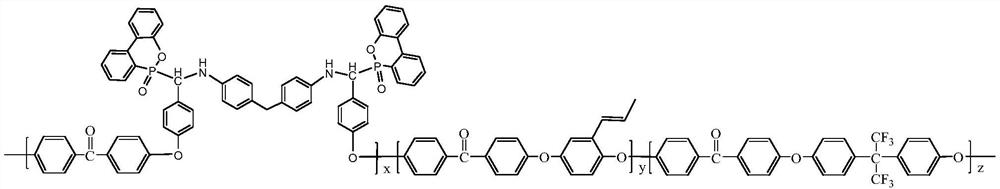

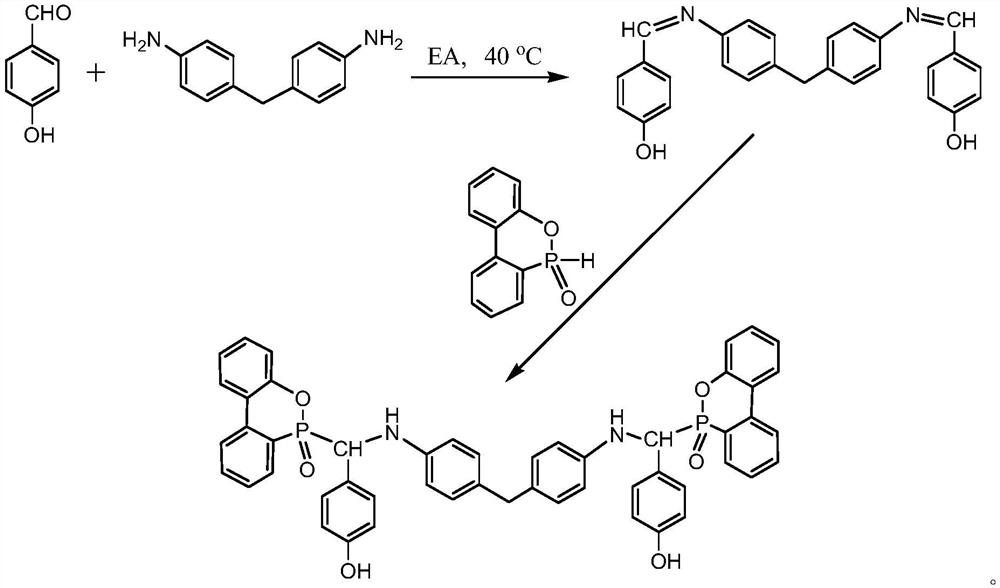

[0027] (1) Preparation of DOPO-substituted bisphenol monomer (I): add 6.1060g of p-hydroxybenzaldehyde, 4.9565g of 4,4'-diaminodiphenylmethane and 90mL of ethyl acetate into a single-necked bottle, stir evenly, In a nitrogen atmosphere, the reaction was carried out at 40 °C for 2 h, and then 10.8085 g of DOPO was added to continue the reaction for 24 h to terminate the reaction. The reaction solution was cooled to room temperature and filtered to obtain a solid. The solid was soaked in ethanol, rinsed, filtered with suction, and vacuum-dried at 60°C for 24 hours to obtain DOPO-substituted bisphenol monomer (I).

[0028]

[0029] (2) Synthesis of DOPO and cross-linked alkenyl polyaryl ether ketone: In a three-necked flask, 1.6777 g (2 mmol) of DOPO-substituted bisphenol monomer (I) and 6.0521 g (18 mmol) of hexafluorobisphenol A were successively added. , 4.3640 g (20 mmol) of difluorobenzophenone, 80 mL of toluene, 100 mL of DMAc, in N at 1 mL / sec 2The reaction was carried...

Embodiment 2

[0033] (1) Preparation of DOPO-substituted bisphenol monomer (II): add 6.1060g of p-hydroxybenzaldehyde, 2.7035g of p-phenylenediamine and 90mL of absolute ethanol into a single-necked bottle, stir evenly, and place in a nitrogen atmosphere at 40°C. The reaction was continued for 2h, and then 10.8085g DOPO was added to continue the reaction for 24h to terminate the reaction. The reaction solution was cooled to room temperature and filtered to obtain a solid. The solid was soaked in ethanol, rinsed, filtered with suction, and vacuum-dried at 60°C for 24 hours to obtain DOPO-substituted bisphenol monomer (II).

[0034] (2) Synthesis of DOPO-containing and cross-linked alkenyl polyaryletherketone: In a three-necked flask, 3.7438 g (5 mmol) of DOPO-containing bisphenol (II), 5.0434 g (15 mmol) of hexafluorobisphenol A, 3.7438 g (15 mmol) of hexafluorobisphenol A, Benzophenone 4.3640 g (20 mmol), toluene 80 mL, DMAc 100 mL, N at 1 mL / sec 2 The reaction was carried out at 140°C for...

Embodiment 3

[0037] (1) Preparation of DOPO-substituted bisphenol monomer (III): add 6.1060g p-hydroxybenzaldehyde, 5.0060g 4,4'-diaminodiphenyl ether and 100mL ethyl acetate into a single-necked bottle, stir evenly, and nitrogen The reaction was carried out at 50 °C for 2 hours in the atmosphere, and then 10.8085g DOPO was added to continue the reaction for 24 hours to terminate the reaction. The reaction solution was cooled to room temperature and filtered to obtain a solid. The solid was soaked in ethanol, rinsed, filtered with suction, and vacuum-dried at 60°C for 24 hours to obtain DOPO-substituted bisphenol monomer (III).

[0038] (2) Synthesis of DOPO and cross-linked alkenyl polyaryl ether ketone: In a three-necked flask, 8.4082 g (10 mmol) of DOPO-containing bisphenol (III), 3.3623 g (10 mmol) of hexafluorobisphenol A, 3.3623 g (10 mmol) of hexafluorobisphenol A, Benzophenone 4.3640 g (20 mmol), toluene 100 mL, DMAc 120 mL, N at 1 mL / sec 2 The reaction was carried out at 140°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com