DOPO and crosslinked alkenyl polyaryletherketone containing cable material and preparation method thereof

A technology of alkenyl polyarylether ketone and alkenyl polyarylether is applied in the field of preparation containing DOPO and cross-linked alkenyl polyarylether ketone, which can solve the problem of many additives, complex preparation process requirements, and reduced ultra-thin-wall insulation Cable reliability and other issues, to achieve the effect of long-lasting flame retardant performance, good stability, high glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

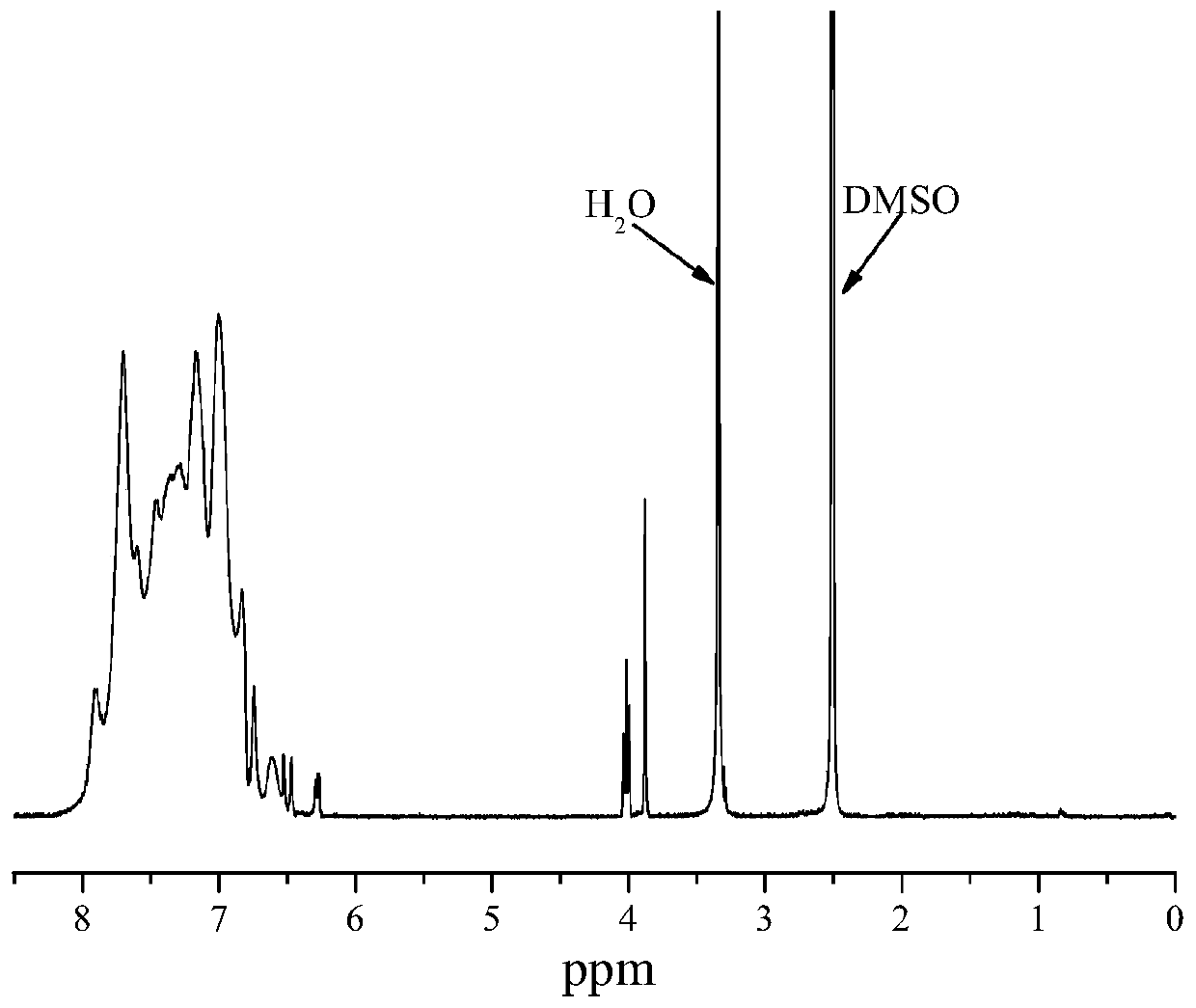

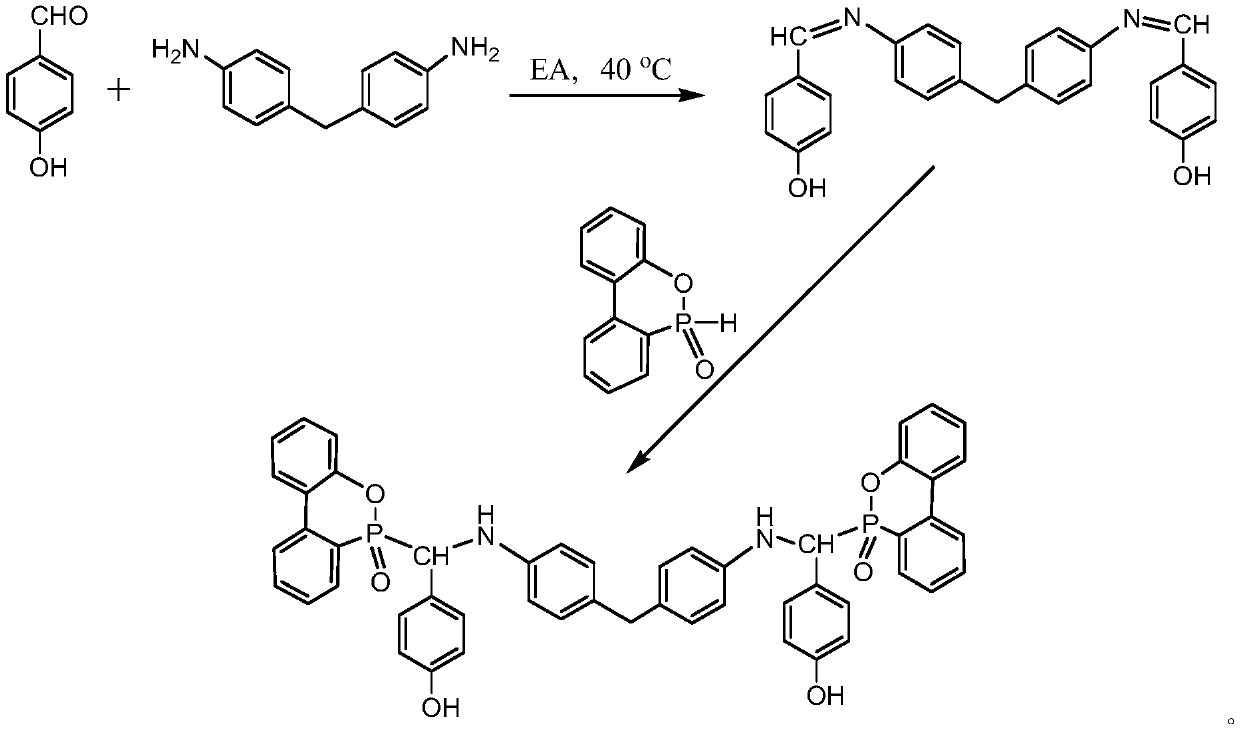

[0027] (1) Preparation of bisphenol monomer (I) containing DOPO substituent: add 6.1060g of p-hydroxybenzaldehyde, 4.9565g of 4,4'-diaminodiphenylmethane and 90mL of ethyl acetate into a single-necked bottle, stir well, React at 40°C for 2 hours in a nitrogen atmosphere, then add 10.8085g DOPO to continue the reaction for 24 hours to terminate the reaction. The reaction solution was cooled to room temperature, filtered to obtain a solid, soaked in ethanol, rinsed, filtered, and vacuum-dried at 60°C for 24 hours to obtain a DOPO-substituted bisphenol monomer (I).

[0028]

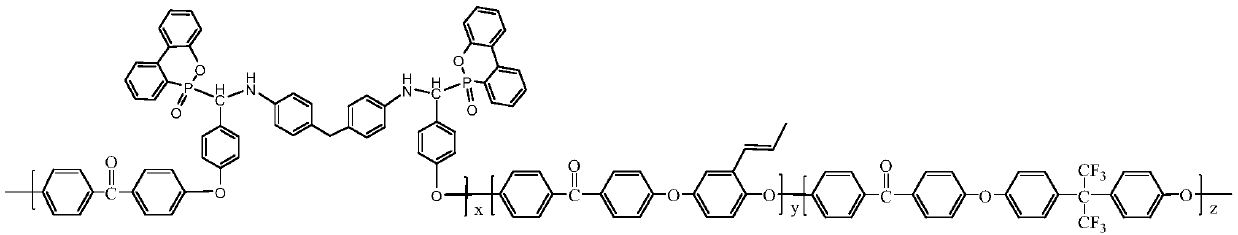

[0029] (2) Synthesis of DOPO-containing and cross-linked alkenyl polyaryletherketone: 1.6777g (2mmol) of bisphenol monomer containing DOPO substituent (I) and 6.0521g (18mmol) of hexafluorobisphenol A were sequentially added to a three-necked flask , difluorobenzophenone 4.3640g (20mmol), toluene 80mL, DMAc100mL, at 1mL / sec N 2Flow down to 140°C for 3 hours, then raise the temperature to 170°C for 8 hour...

Embodiment 2

[0033] (1) Preparation of bisphenol monomer (II) containing DOPO substituent: add 6.1060g of p-hydroxybenzaldehyde, 2.7035g of p-phenylenediamine and 90mL of absolute ethanol into a one-mouth bottle, stir evenly, and place the mixture in a nitrogen atmosphere at 40°C React for 2h, then add 10.8085gDOPO to continue the reaction for 24h, and terminate the reaction. The reaction solution was cooled to room temperature, filtered to obtain a solid, soaked in ethanol, rinsed, filtered, and vacuum-dried at 60°C for 24 hours to obtain a DOPO-substituted bisphenol monomer (II).

[0034] (2) Synthesis of DOPO-containing and cross-linked alkenyl polyaryletherketone: 3.7438g (5mmol) of DOPO-containing bisphenol (II), 5.0434g (15mmol) of hexafluorobisphenol A, 5.0434g (15mmol) of hexafluorobisphenol A, difluoro Benzophenone 4.3640g (20mmol), toluene 80mL, DMAc100mL, in 1mL / sec N 2 Flow down to 140°C for 3 hours, then raise the temperature to 170°C for 7 hours, stop heating and naturally c...

Embodiment 3

[0037] (1) Preparation of bisphenol monomer (Ⅲ) containing DOPO substituent: add 6.1060g of p-hydroxybenzaldehyde, 5.0060g of 4,4'-diaminodiphenyl ether and 100mL of ethyl acetate into a one-mouth bottle, stir well, and nitrogen React at 50°C for 2 hours in the atmosphere, then add 10.8085g DOPO to continue the reaction for 24 hours, and terminate the reaction. The reaction solution was cooled to room temperature, filtered to obtain a solid, soaked in ethanol, rinsed, filtered, and vacuum-dried at 60°C for 24 hours to obtain a DOPO-substituted bisphenol monomer (Ⅲ).

[0038] (2) Synthesis of DOPO-containing and cross-linked alkenyl polyaryletherketone: 8.4082g (10mmol) of DOPO-containing bisphenol (Ⅲ), 3.3623g (10mmol) of hexafluorobisphenol A, difluorobisphenol A Benzophenone 4.3640g (20mmol), toluene 100mL, DMAc120mL, in 1mL / sec N 2 Flow down to 140°C for 3 hours, then raise the temperature to 170°C for 15 hours, stop heating and naturally cool down to 80°C, then add 0.3022...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com