Flame retardant with nitrogen-containing phosphonate and synthesis method of flame retardant

A technology of nitrogen phosphonate and synthesis method, applied in the field of flame retardant and its synthesis, can solve the problems of low flame retardant efficiency, large addition amount, poor durability, etc. Flammability, transfer inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

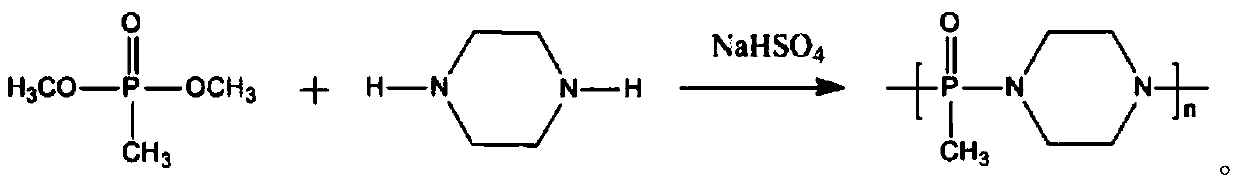

[0013] Specific embodiment 1: The chemical name of a nitrogen-containing phosphonate flame retardant in this embodiment is polymethylpiperazine phosphonate, and its structural formula is:

[0014] Where n is 10-100.

specific Embodiment approach 2

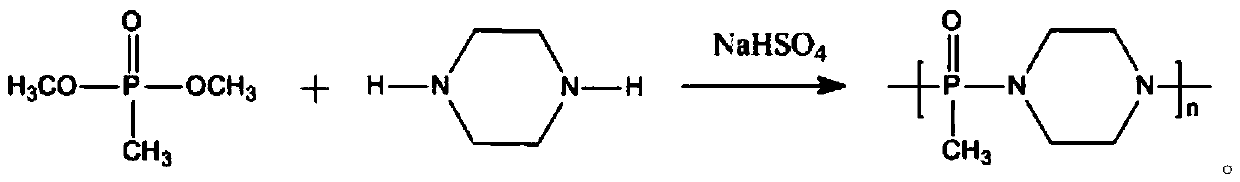

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the synthesis method of the nitrogen-containing phosphonate flame retardant is specifically carried out in the following steps:

[0016] 1. After mixing and stirring dimethyl methyl phosphate, piperazine and catalyst, carry out distillation reaction, and collect fractions;

[0017] 2. Cool down after the reaction, add ethanol and stir thoroughly, separate solid and liquid, and distill the liquid phase to remove ethanol to obtain a light yellow viscous liquid product.

[0018] In this embodiment, the purpose of adding ethanol to fully stir the solid-liquid separation is to remove unreacted piperazine and catalyst.

[0019] The synthesis method of the nitrogen-containing phosphonate flame retardant described in this embodiment is realized through the following reaction process:

[0020]

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the catalyst described in step 1 is sodium bisulfate. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com