Non-woven fabric with superfine fiber and preparing method and application of non-woven fabric

A superfine fiber, non-woven technology, applied in textiles and papermaking, preparations for skin care, non-woven fabrics, etc., can solve the problems of decreased uniformity, more neps, more flying flowers, etc. And the effect of less cotton and less friction and static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

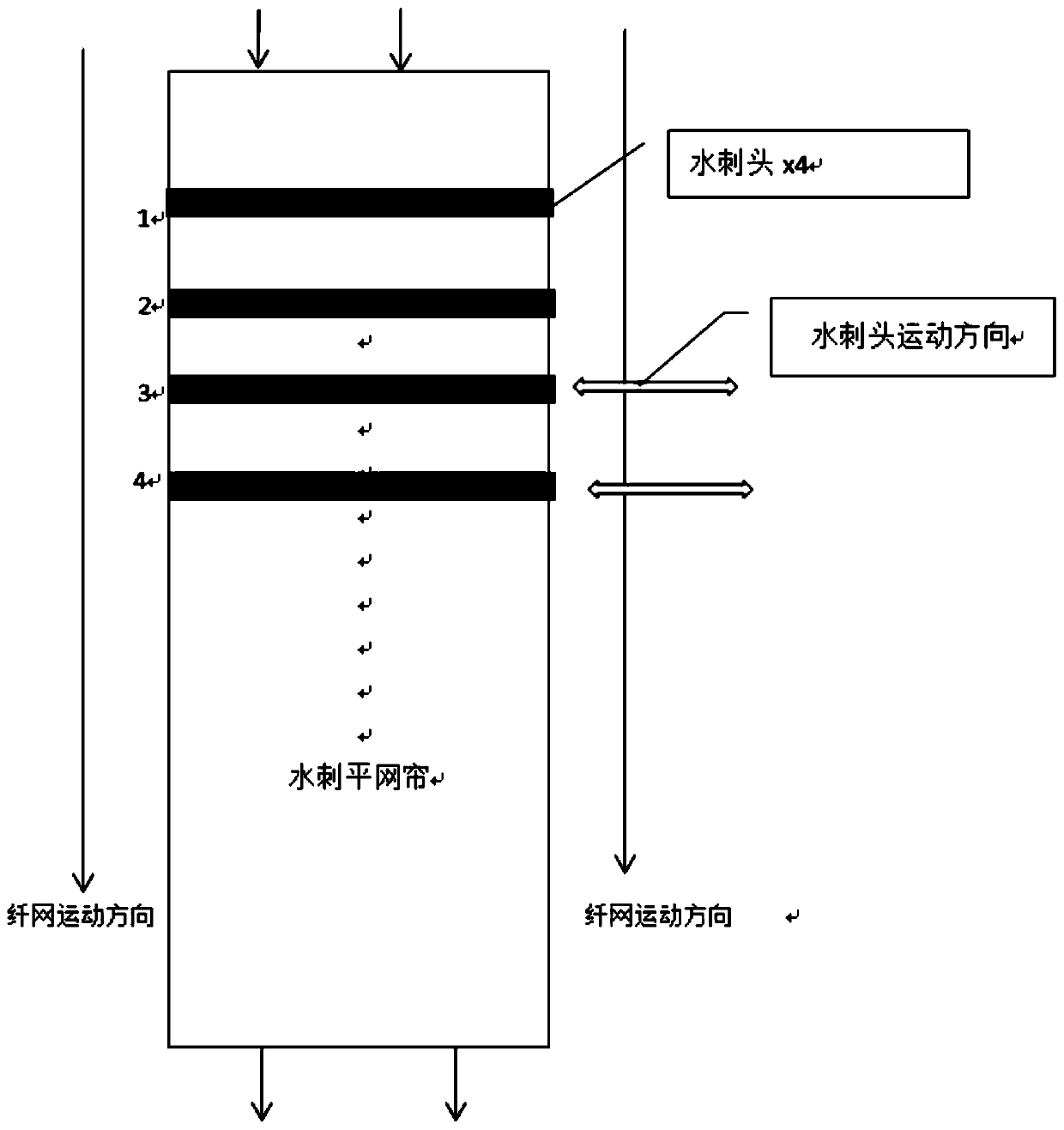

[0028] A preparation method of a non-woven fabric containing microfibers, the steps are as follows:

[0029] 1. Mix 6 parts by weight of superfine fibers and 4 parts by weight of Tencel fibers to obtain mixed fibers. The fiber fineness of the ultrafine fiber is 0.45dtex, which is the product of mixed wood pulp of broad-leaved forest and coniferous forest through spinning processing, and comes from Japan Omikenshi Company. The fiber fineness of the Tencel fiber is 1dtex, and it comes from Austrian Lenzing Company.

[0030] 2. Place the mixed fibers above in a closed environment with a humidity of 80% for 24 hours to raise cotton. The method of ultrasonic atomization and humidification is used to maintain the humidity of the closed environment at 80%. This step can reduce the frictional static electricity of fibers with small fineness, reduce the phenomenon of flying flowers and cotton particles in the subsequent process, and improve the uniformity of the cotton web. .

[003...

Embodiment 2

[0039] A preparation method of a non-woven fabric containing microfibers, the steps are as follows:

[0040] 1. Mix 5 parts by weight of superfine fibers and 5 parts by weight of Tencel fibers to obtain mixed fibers. Get mixed fibers. The fiber fineness of the ultrafine fiber is 0.45dtex, which is the product of mixed wood pulp of broad-leaved forest and coniferous forest through spinning processing, and comes from Japan Omikenshi Company. The fiber fineness of the Tencel fiber is 1dtex, and it comes from Austrian Lenzing Company.

[0041] 2. Put the mixed fibers above in a closed environment with a humidity of 90% for 30 hours to raise cotton. The humidity of the closed environment is maintained at 90% by means of ultrasonic atomization humidification.

[0042] 3. Using a carding machine to card the mixed fibers after raising the cotton into a web to obtain a fiber web.

[0043] Cotton feeding is carried out by weighing and feeding with weighing curtains. The rotating spe...

Embodiment 3

[0050] A preparation method of a non-woven fabric containing microfibers, the steps are as follows:

[0051] 1. Mix 6 parts by weight of superfine fibers and 4 parts by weight of Tencel fibers to obtain mixed fibers. The fiber fineness of the ultrafine fiber is 0.45dtex, which is the product of mixed wood pulp of broad-leaved forest and coniferous forest through spinning processing, and comes from Japan Omikenshi Company. The fiber fineness of the Tencel fiber is 1dtex, and it comes from Austrian Lenzing Company.

[0052] 2. Place the mixed fibers above in a closed environment with a humidity of 80% for 24 hours to raise cotton. The humidity of the closed environment is maintained at 80% by means of ultrasonic atomization humidification.

[0053] 3. Using a carding machine to card the mixed fibers after raising the cotton into a web to obtain a fiber web.

[0054] Cotton feeding is carried out by weighing and feeding with weighing curtains. The rotation speed of the main cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com