Self-extinguishing flame-retardant cotton fabric and preparation method and application thereof

A flame-retardant cotton, self-extinguishing technology, applied in the direction of textiles and papermaking, plant fiber, fiber treatment, etc., can solve the problems of poor flame-retardant performance, poor thermal stability of cotton fabrics, etc., to reduce production costs and solve poor thermal stability , to avoid the effect of mutual contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Cotton fabric (95g / m 2 ), and then adopt the method of alternate spraying to apply 5wt% sodium alginate aqueous solution (pH=9) and 2wt% ammonium polyphosphate aqueous solution (pH=9) with 1wt% silane coupling agent aqueous solution (pH=4) Deposit on the surface of cotton fabric layer by layer; the amount of each spray solution is 10 ml / square meter, and the cotton fabric is air-dried or dried, and the process is repeated, with silane coupling agent / sodium alginate / silane coupling agent / polyphosphoric acid The ammonium four-layer is a flame-retardant unit layer until five flame-retardant unit layers are deposited on the surface of the cotton fabric to obtain a coated cotton fabric.

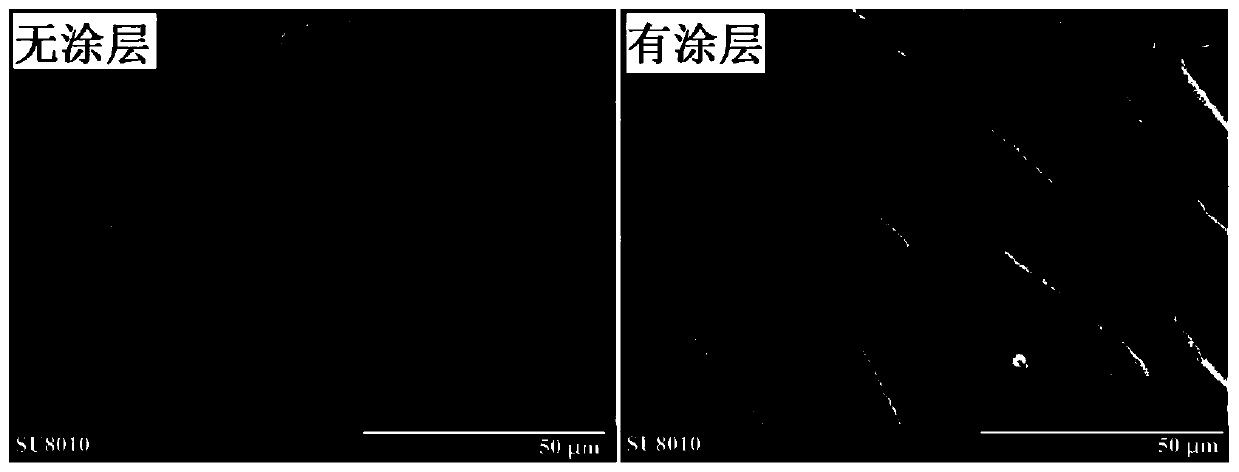

[0032] Microstructure characterization: the SEM figure of the pure cotton fabric of the present embodiment and coated cotton fabric, as figure 1 As shown, it can be seen that the surface of the fiber before finishing is smooth and clean, while the surface of the cotton fabric after finish...

Embodiment 2

[0038] Cotton fabric (95g / m 2), and then alternately spraying 5wt% sodium alginate solution (pH=9) and 2wt% ammonium polyphosphate solution (pH=9) with 1wt% silane coupling agent solution (pH=4) Deposit on the surface of cotton fabric layer by layer; the amount of each spray solution is 10 ml / square meter, and the cotton fabric is air-dried or dried, and the process is repeated, with silane coupling agent / ammonium polyphosphate / silane coupling agent / alginic acid The four layers of sodium are one flame retardant unit layer, until five flame retardant unit layers are deposited on the surface of the cotton fabric to obtain the coated cotton fabric.

[0039] Microstructure characterization: It can be seen that the surface of the fiber before coating treatment is smooth and clean, while the surface of the cotton fabric after finishing is rough, indicating that the coating is successfully deposited on the surface of the fabric.

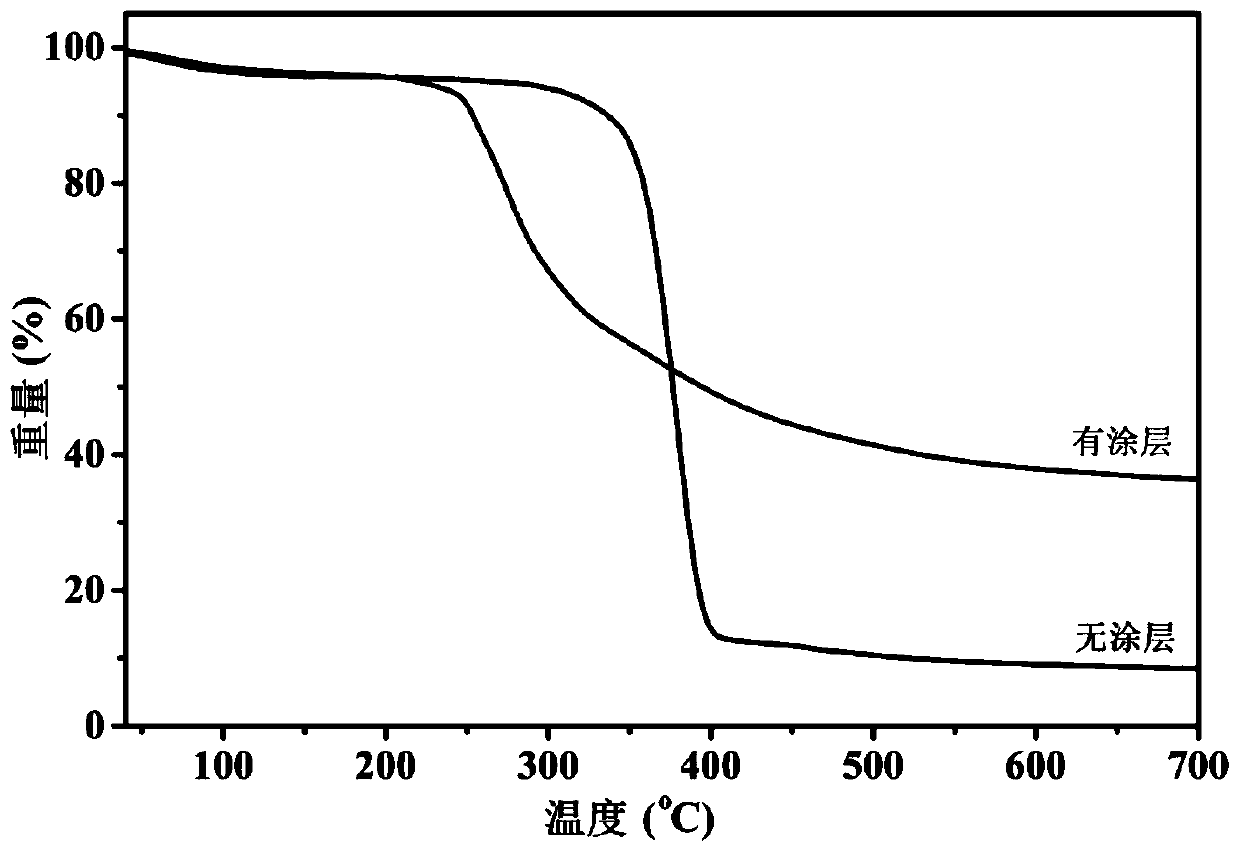

[0040] Flame retardant performance test: the thermal...

Embodiment 3

[0045] Cotton fabric (120g / m 2 ), and then alternately spraying the 3wt% sodium alginate solution (pH=9) and the 1wt% ammonium polyphosphate solution (pH=9) with the 5wt% silane coupling agent solution (pH=4) Deposit layer by layer on the surface of cotton fabric; the amount of each spray solution is 15 ml / square meter, and the cotton fabric is air-dried or dried, and the process is repeated, with silane coupling agent / sodium alginate / silane coupling agent / polyphosphoric acid The ammonium four-layer is a flame-retardant unit layer, until 10 flame-retardant unit layers are deposited on the surface of the cotton fabric to obtain a coated cotton fabric.

[0046] Microstructure characterization: It can be seen that the surface of the fiber before coating treatment is smooth and clean, while the surface of the cotton fabric after finishing is rough, indicating that the coating is successfully deposited on the surface of the fabric.

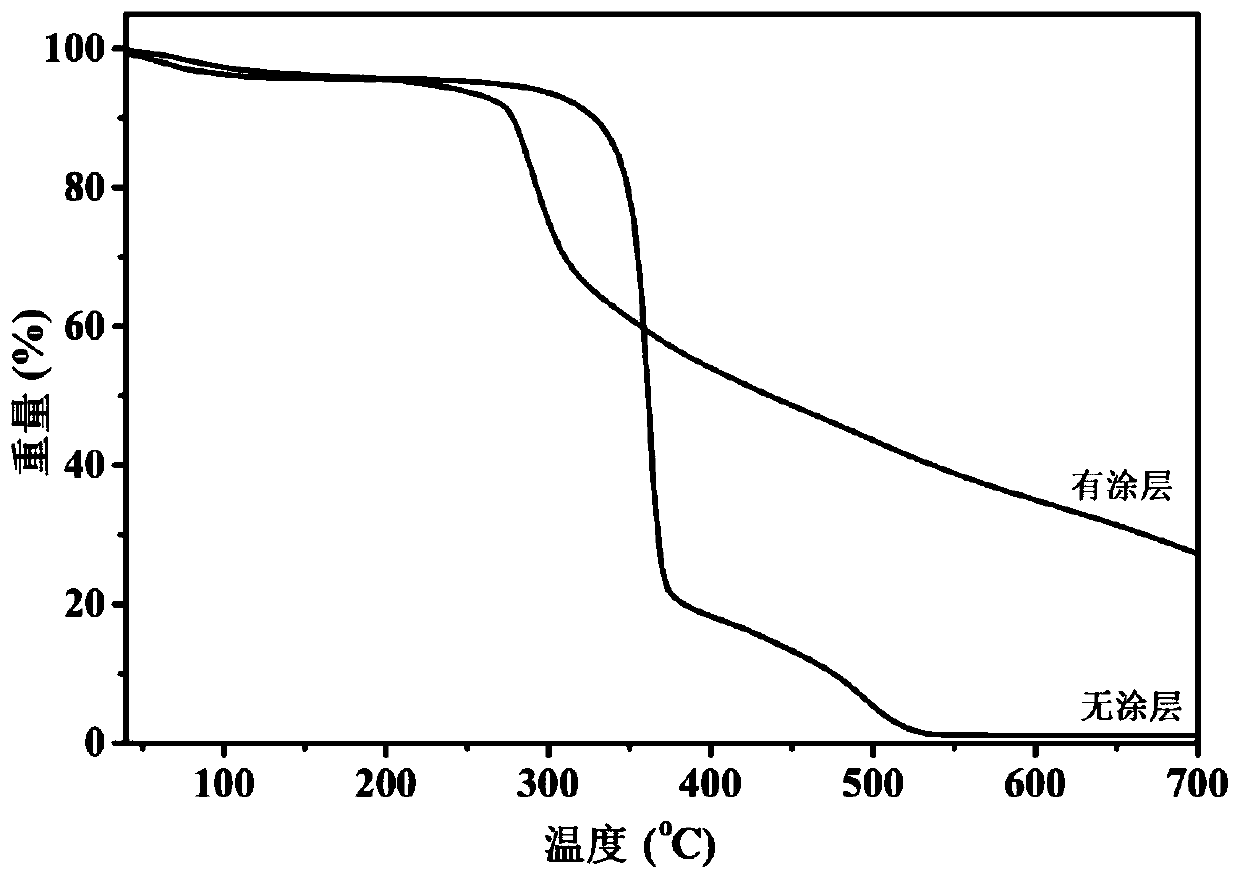

[0047] Flame retardant performance test: the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com