Steel structure anti-seismic floor slab for building and its manufacturing method

A technology for steel structures and buildings, applied in building components, building structures, buildings, etc., can solve problems such as fractures and poor seismic performance of integral floor slabs, and achieve the effect of speeding up the project progress, enhancing seismic resistance and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

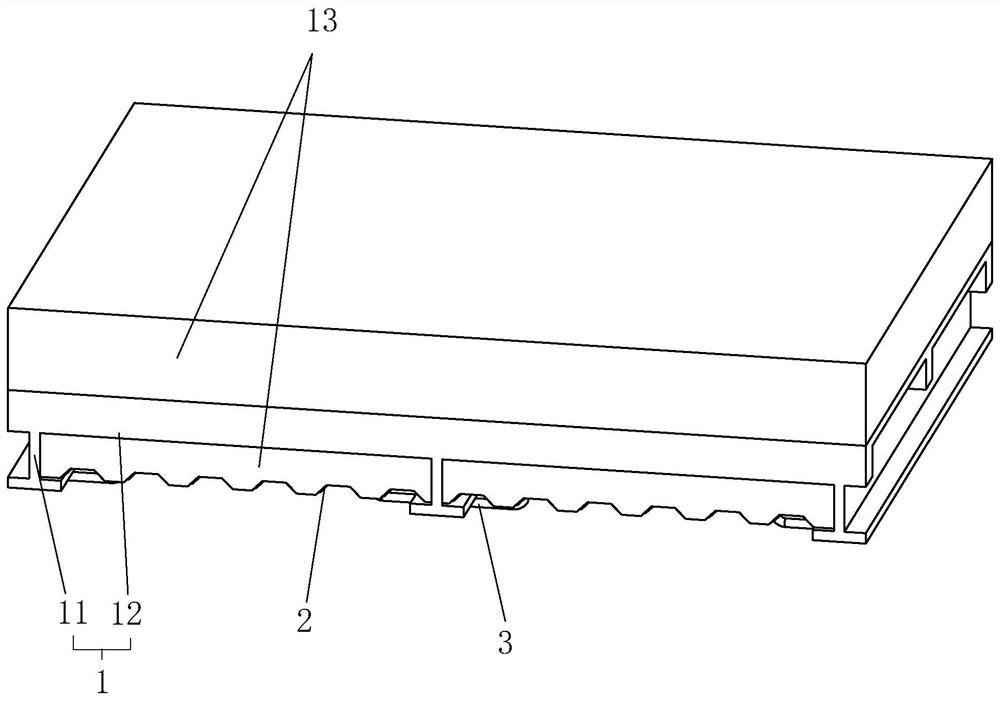

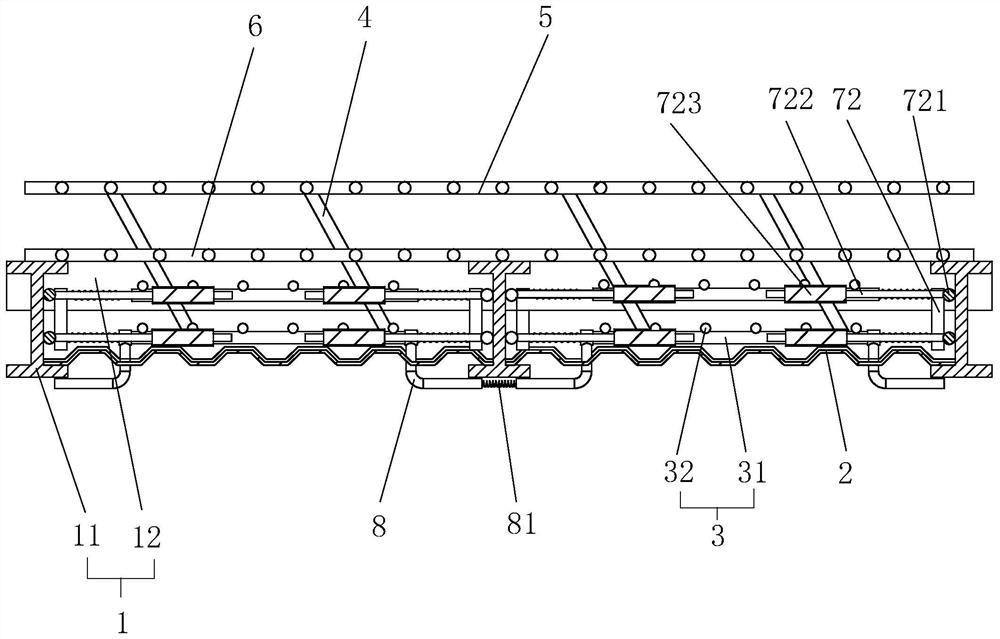

[0047] refer to figure 1 and figure 2 , is an anti-seismic floor slab of a steel structure for construction disclosed by the present invention, which is arranged on a steel beam 1. The steel beam 1 includes a main beam 11 and a connecting beam 12, and the connecting beam 12 is connected between adjacent and parallel main beams 11 , the connecting beam 12 is perpendicular to the main beam 11, the main beam 11 is a main beam 11 of I-shaped steel structure, the steel beam 1 is provided with a concrete filling layer 13, and the lower plates of two adjacent main beams 11 are provided with a floor deck 2 , the floor deck 2 is located below the concrete filling layer 13, and the embossing on the surface of the floor deck 2 makes the bonding between the floor deck 2 and the concrete filling layer 13 intimate, so that the floor has a strong bearing capacity; the upper part of the floor deck 2 is set There are connecting components, which are embedded in the concrete filling layer 13 ...

Embodiment 2

[0053] A method for manufacturing a steel structure anti-seismic floor slab for a building. The specific method is: S1: Open two rows of evenly distributed positioning holes 21 at positions close to both ends of the floor deck 2, and each row of positioning holes 21 is parallel to the main beam 11 .

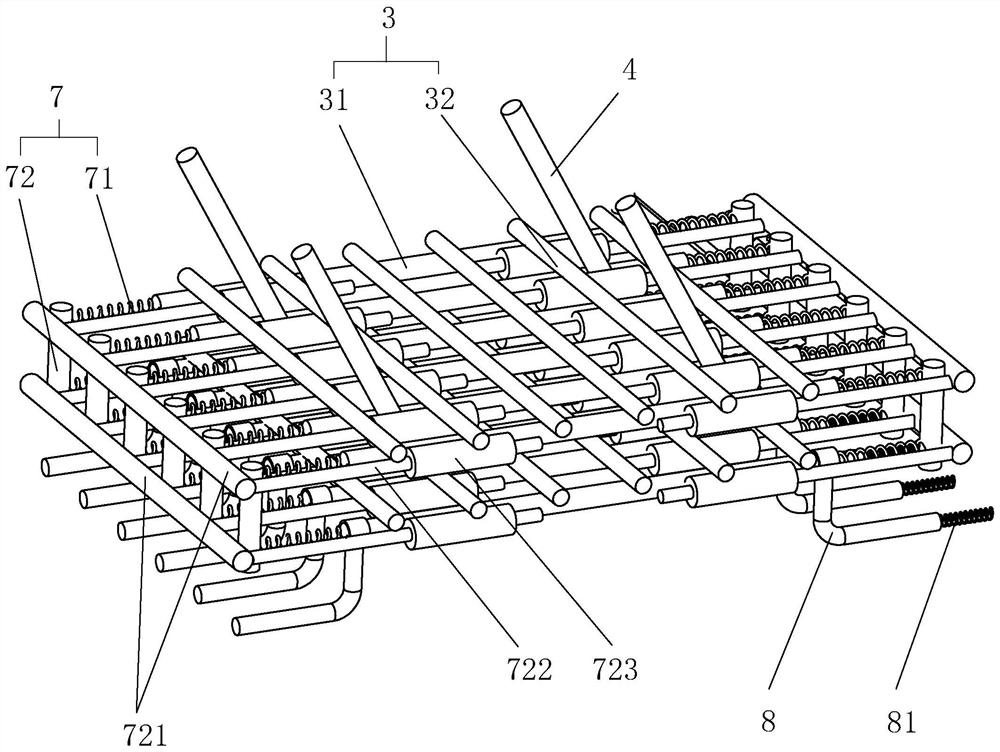

[0054] S2: According to the size of the rectangular interval divided by the main beam 11 by the connecting beam 12, the horizontal bars 31 and the longitudinal bars 32 are fixedly connected to form a reinforcement mesh 3, so that the horizontal bars 31 of the upper and lower reinforcement meshes 3 correspond to the vertical bars up and down , welding a plurality of connecting bars 4 between the upper and lower two steel meshes 3, the upper end of the connecting bars 4 exceeds the height of the steel mesh 3.

[0055] S3: Prefabricated connection assembly, weld the two ends of the transverse rib 31 to the elastic member 71, so that the deformation direction of the elastic member 71...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com