Detection method for heavy metal ions

A kind of technology of heavy metal ion, detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

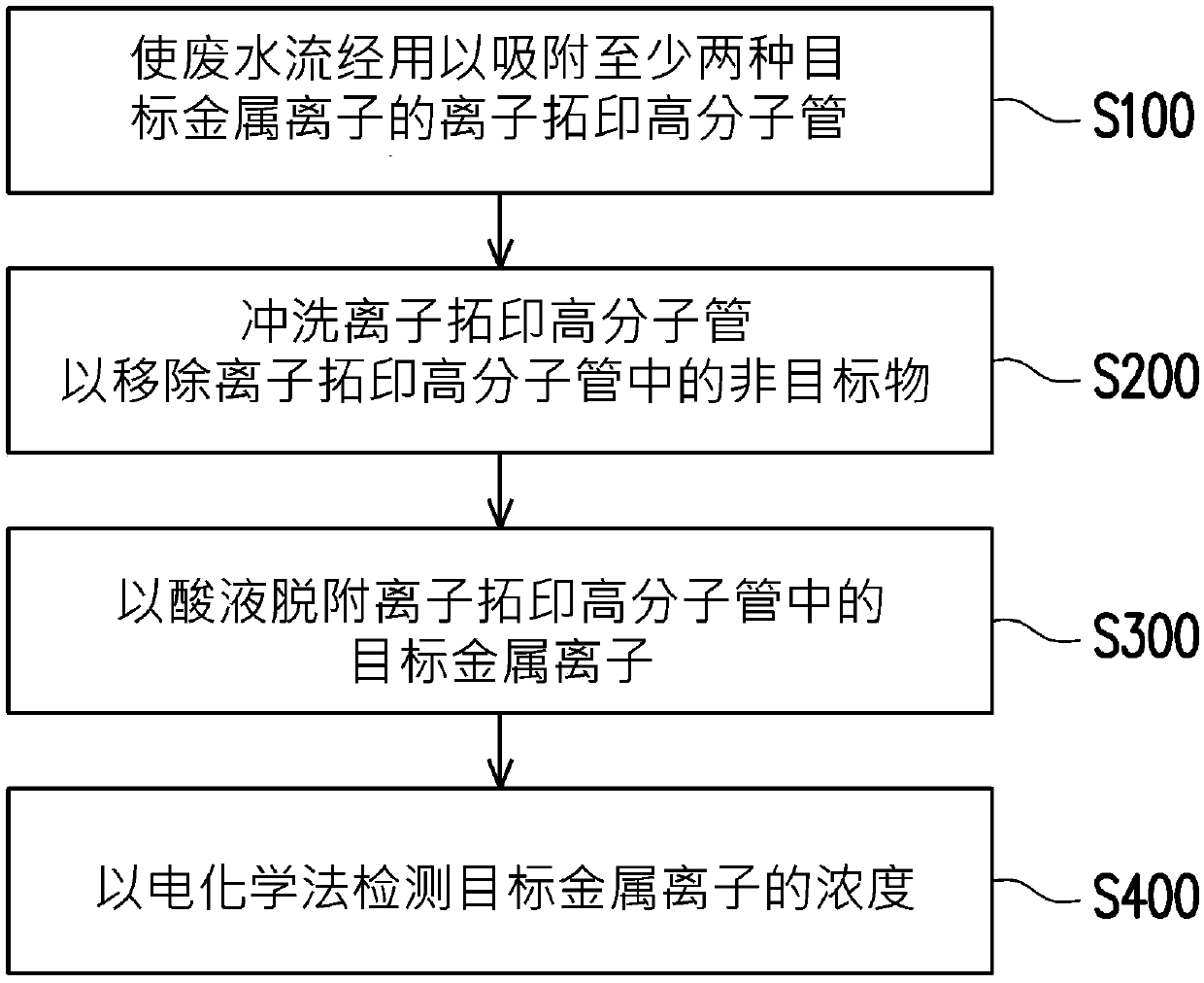

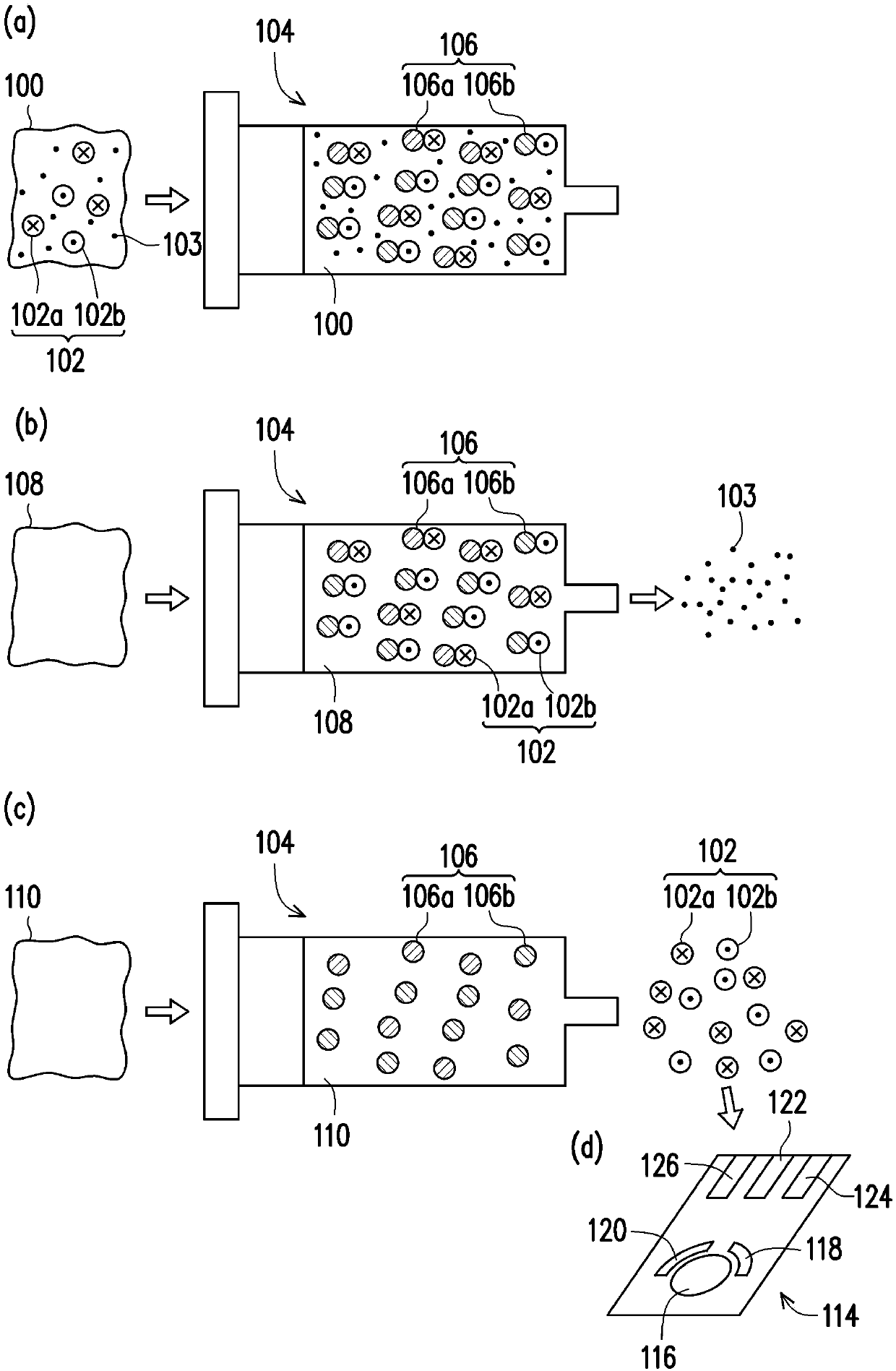

[0048] Wastewater is provided with a pH of approximately 6 and a conductivity of approximately 2,000 microSiemens / cm. Next, 2 ppm of copper ions were added to the wastewater. After that, make the waste water flow through the ion rubbing polymer tube with the copper ion rubbing polymer to adsorb the copper ion.

[0049] The detailed preparation method of copper ion rubbing polymer is as follows, 4 mmole of 4-vinylpyridine (4-vinylpyridine) (as a functional group monomer) and 0.5 mmole of copper nitrate (Cu(NO 3 ) 2 ) (as a template ion) was added to 35ml of acetonitrile and stirred overnight. Get 20mmole of ethylene glycol dimethacrylate (EGDMA) (as cross-linking agent) and add in the solution, the solution is passed into N 2 remove O from the solution 2 , the solution was placed in an oil bath at 65° C., and 100 mg of azobisisobutyronitrile (AIBN) (as an initiator) was added to the solution and stirred for 24 hours. After the reaction is completed, the produced powder is ...

experiment example 2

[0061] Wastewater is provided with a pH of approximately 6 and a conductivity of approximately 2,000 microSiemens / cm. Next, 2 ppm of lead ions were added to the wastewater. After that, make the waste water flow through the ion rubbing polymer tube with the lead ion rubbing polymer to adsorb the lead ion.

[0062] The detailed preparation method of lead ion rubbing polymer is as follows, 0.89g of 1-vinylimidazole (1-vinylimidazole) and 0.0828g of lead nitrate Pb(NO 3 ) 2 Add 5 ml of tetrahydrofuran (Tetrahydrofuran, THF) and stir for 30 minutes. Then take 0.13g of 3-(trimethoxysilyl)propylmethacrylate (3-(trimethoxysilyl)propylmethacrylate, TMSPMA) and 2ml of tetrahydrofuran and add it to the solution, and the solution is introduced into the N 2 remove O from the solution 2 , put the solution in an oil bath at 68°C, then add 1.6 mg of AIBN to the solution and stir for 16 hours. After the reaction is completed, the resulting powder is washed several times with 2M nitric aci...

experiment example 3

[0073] Copper ion rubbing polymer (manufacturing method is the same as in Experimental Example 1) and lead ion rubbing polymer (manufacturing method is the same as Experimental Example 2) are mixed with silica sand (trade name: Aldrich 806765, particle size is 3 μm, purchased from SigmaAldrich) . Then fill in the ion-tapping polymer tube. Next, simulated wastewater with a conductivity of approximately 2,400 microSiemens / cm was provided, and 10 ppm of copper ions and 10 ppm of lead ions were added to the simulated wastewater.

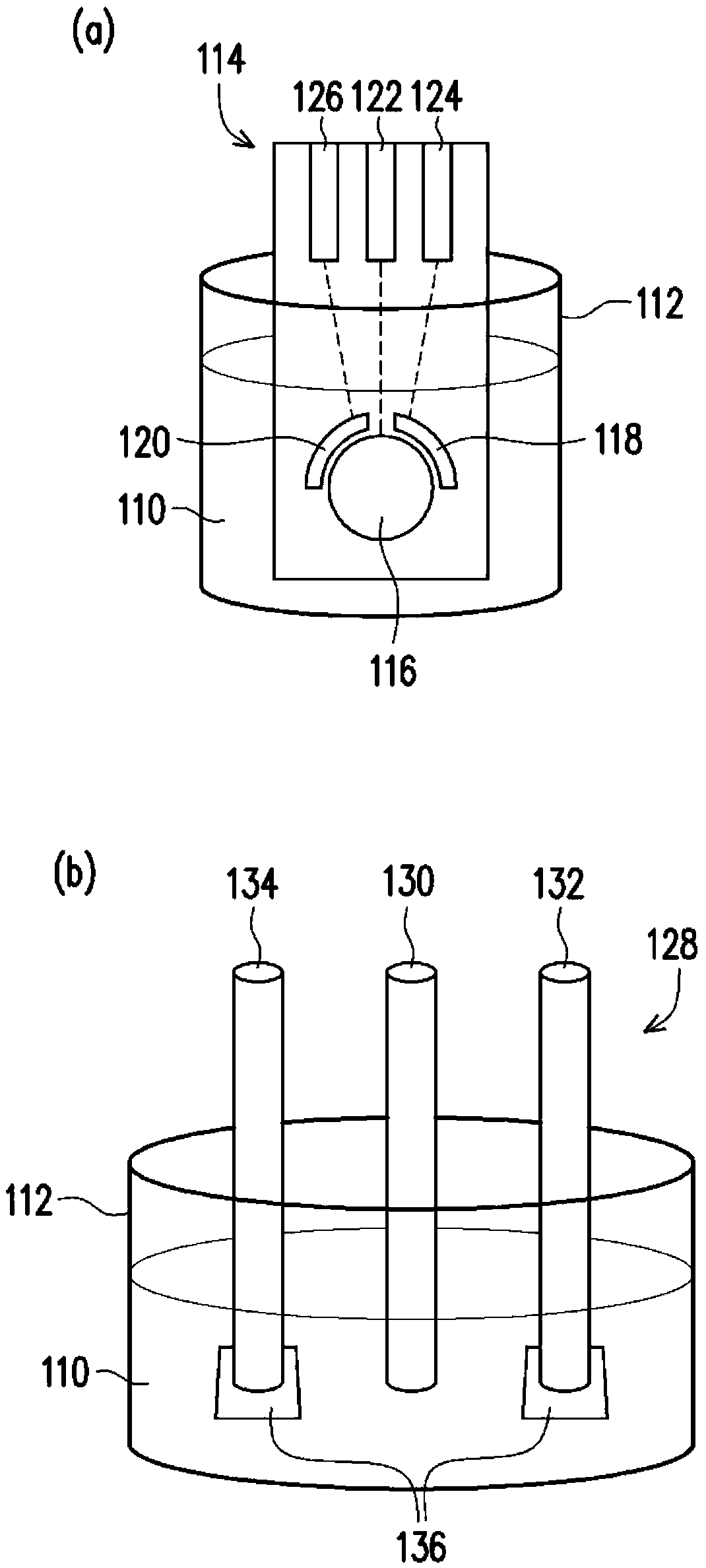

[0074] Afterwards, the simulated waste water is made to flow through the ion rubbing polymer tube having the copper ion rubbing polymer and the lead ion rubbing polymer, so as to adsorb the copper ion and the lead ion. Next, rinse the ion-tapping polymer tube with deionized water to remove the matrix. Then, use hydrochloric acid with a pH value of about 2 to desorb copper ions and lead ions. Finally, the screen-printed three-electrode electrode plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com