Coconut fat film dust collection composite material and its preparation method and application

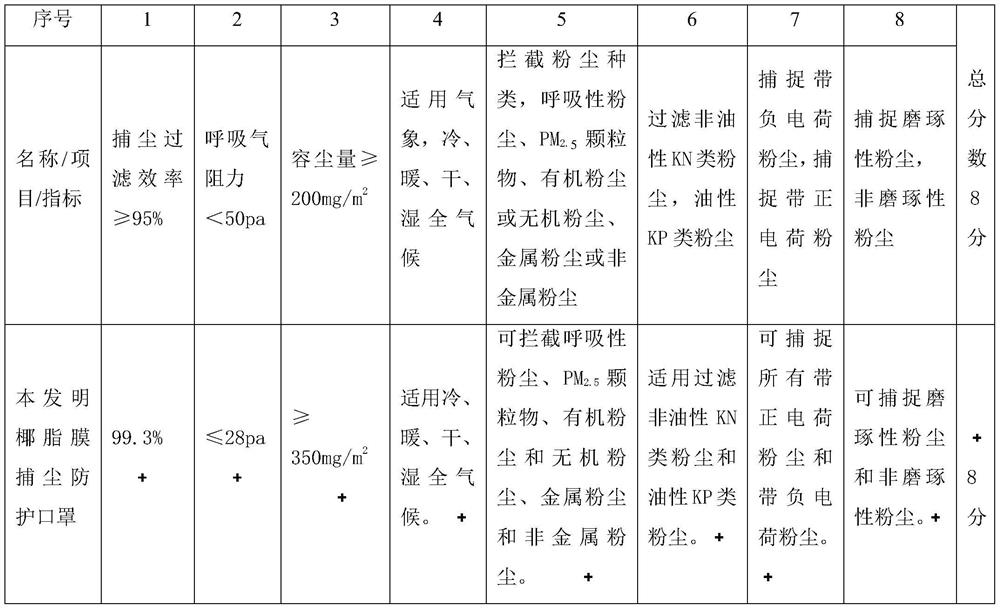

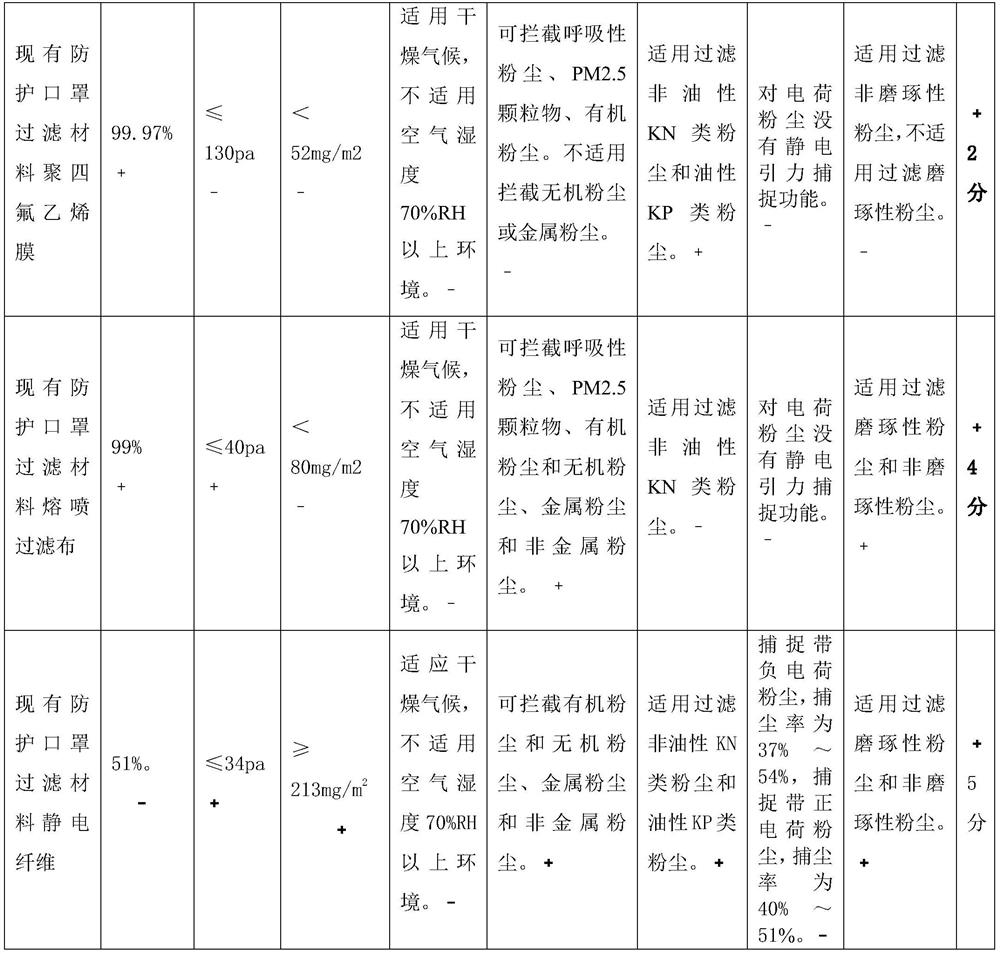

A composite material, coconut fat film technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of low dust holding capacity, poor wear resistance, high humidity, and reduced charge reduction, and achieve ideal effects and air permeability. Good performance and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment one, the preparation of coconut fat film dust collection composite material:

[0052] 1. Prepare coconut fat film solution: mix coconut oil (food grade), amino acid, and lecithin in a weight ratio of 1:2:2, add pure water and stir for 15 minutes, then add pectin and continue stirring for 15 minutes to obtain coconut fat Membrane solubles. Wherein the weight of pure water is 2 times of coconut oil, amino acid, lecithin raw material mixture, pectin addition is 0.6wt% of coconut oil, amino acid, lecithin raw material mixture.

[0053] 2. Preparation of coconut fat film: After the coconut fat film solution is purified by a filter, it is injected into the casting machine production line to form a sheet-like casting film, and then the coconut fat film is obtained by traction, trimming, and winding. After testing, its porosity is 91.5%.

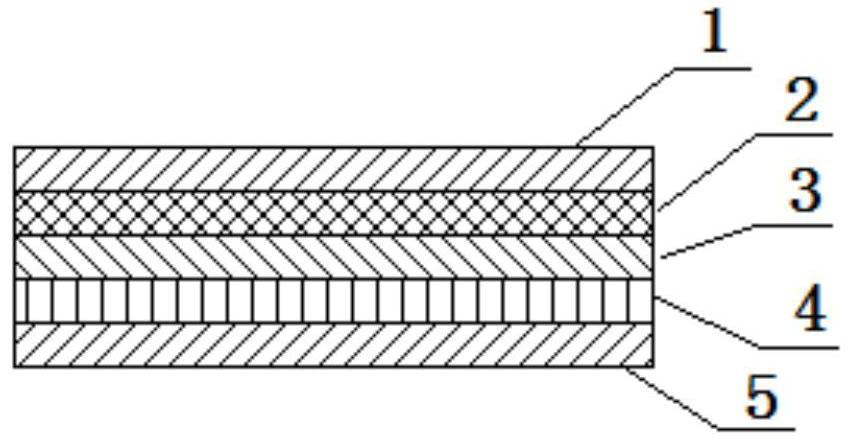

[0054] 3. Preparation of coconut fat film composite material: the coconut fat film is attached to the hot-air non-woven fabric ...

Embodiment 2

[0056] Embodiment two, the preparation of coconut fat film dust collection composite material:

[0057] 1. Prepare coconut fat film solution: mix coconut oil (food grade), amino acid, and lecithin in a weight ratio of 1:2:2, add pure water and stir for 15 minutes, then add pectin and continue stirring for 15 minutes to obtain coconut fat Membrane solubles. Wherein the weight of pure water is 3 times of coconut oil, amino acid, lecithin raw material mixture, pectin addition is 0.4wt% of coconut oil, amino acid, lecithin raw material mixture.

[0058] 2. Preparation of coconut fat film: After the coconut fat film solution is purified by a filter, it is injected into the casting machine production line to form a sheet-like casting film, and then the coconut fat film is obtained by traction, trimming, and winding. After testing, its porosity is 89.3%.

[0059]3. Preparation of coconut fat film composite material: the coconut fat film is attached to the hot-air non-woven fabric a...

Embodiment 3

[0061] Embodiment three, the preparation of coconut fat film dust collection composite material:

[0062] 1. Preparation of coconut fat film solution: mix coconut oil derivatives, amino acids, and lecithin in a ratio of 1:2:2 by weight, add pure water and stir for 15 minutes, then add pectin and continue stirring for 15 minutes to obtain coconut fat film solution thing. Wherein the weight of pure water is 4 times of the raw material mixture of coconut oil derivative, amino acid and lecithin, and the added amount of pectin is 0.3wt% of the raw material mixture of coconut oil derivative, amino acid and lecithin.

[0063] 2. Preparation of coconut fat film: After the coconut fat film solution is purified by a filter, it is injected into the casting machine production line to form a sheet-like casting film, and then the coconut fat film is obtained by traction, trimming, and winding. After testing, its porosity is 93.1%.

[0064] 3. Preparation of coconut fat film composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com