A kind of preparation method of water-resistant and antibacterial acrylic acid emulsion

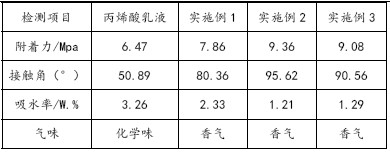

An acrylic emulsion and emulsion technology, applied in the field of coatings, can solve the problems of environmental protection and safety of contact coatings, and achieve the effects of inhibiting the activity of grape aureus and typhoid bacillus, good skin affinity, and overcoming water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of modified silk fibroin.

[0029] (a) Take 20g of silk and put it into a 500mL three-necked bottle filled with 200mL of 0.5% sodium carbonate solution, adjust the pH of the solution to 9 with 1% ammonia solution, raise the temperature to 40°C, and stir at 180r / min for 2 hours , centrifuged and washed three times at 4000r / min, and dried at 60°C to obtain silk fibroin A.

[0030] (b) Weigh 8g of silk fibroin and 200mL of 30% sodium carbonate solution and mix them into a 500mL three-neck flask. Stir for 30min at a temperature of 80°C and a speed of 150r / min. After the stirring is completed, suction filter. The filtrate was put into a dialysis bag and dialyzed with distilled water for 3 days to obtain a silk fibroin solution, and then dried at 60°C to obtain silk fibroin B.

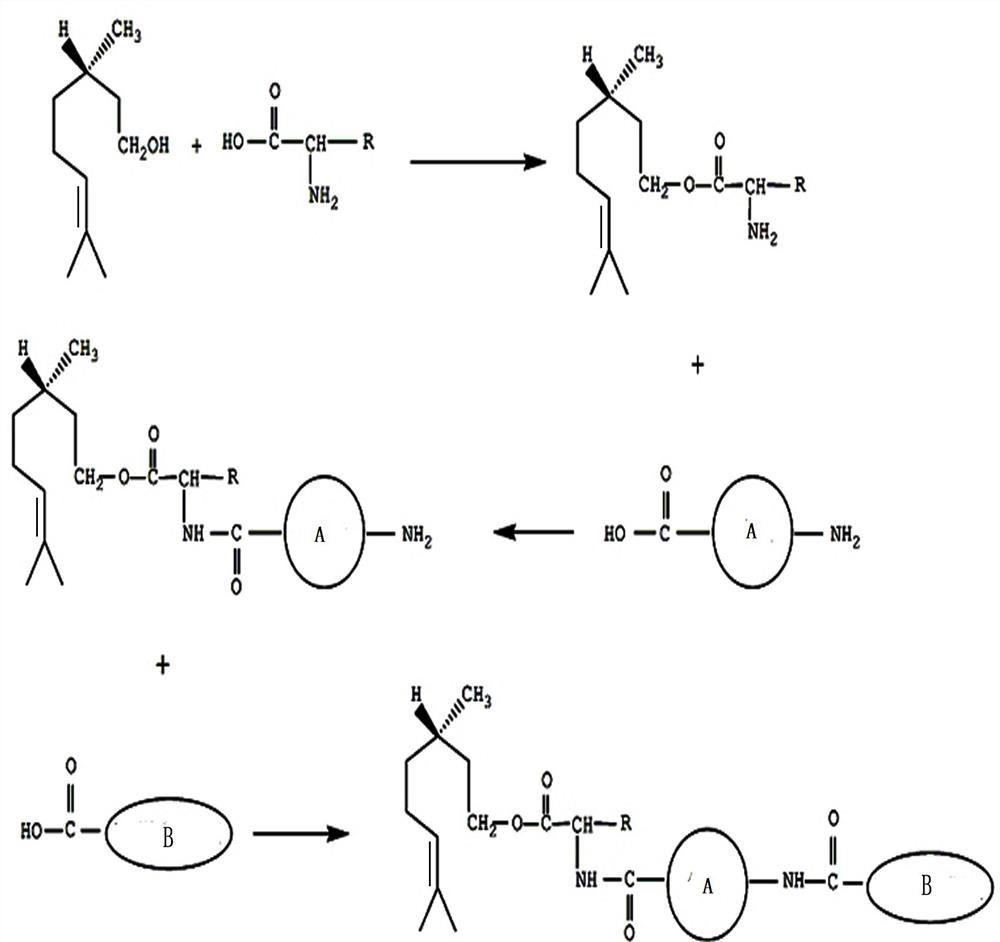

[0031] (c) Put 60 mL of citronellol solution into a 150 mL three-neck flask, add 20 mL of serine solution, 5 mL of 98% concentrated sulfuric acid, and stir for 10 h at 80 °C and 250 r...

Embodiment 2

[0035] (1) Preparation of modified silk fibroin.

[0036] (a) Put 20g of silk into a three-necked bottle filled with 200mL of 0.5% sodium carbonate solution, adjust the pH of the solution to 9 with 1% ammonia solution, raise the temperature to 40°C, and stir at 180r / min for 2 hours. Centrifuge and wash 3 times at 4000r / min, and dry at 60°C to obtain silk fibroin A.

[0037] (b) Weigh 8g of silk fibroin A and 200 mL of 30% sodium carbonate solution, mix them into a three-neck flask, stir for 30min at a temperature of 80°C and a speed of 150r / min, after the stirring is completed, suction filter, and the filtrate Put it into a dialysis bag and dialyze with distilled water for 3 days to obtain a silk fibroin solution, and then dry it at 60°C to obtain silk fibroin B.

[0038] (c) Take 70 mL of citronellol solution into a three-necked flask, add 25 mL of serine solution, 5 mL of 98% concentrated sulfuric acid, and stir for 10 h at 80 °C and 250 r / min. Then at a speed of 5000r / min...

Embodiment 3

[0042] (1) Preparation of modified silk fibroin.

[0043] (a) Take 20g of silk and put it into a 500mL three-necked bottle filled with 200mL of 0.5% sodium carbonate solution, adjust the pH of the solution to 9 with 1% ammonia solution, raise the temperature to 40°C, and stir at 180r / min After 2 h, centrifuge and wash 3 times at 4000 r / min, and dry at 60°C to obtain silk fibroin A.

[0044] (b) Weigh 8g of silk fibroin A and 200mL of 30% sodium carbonate solution and mix them into a three-neck flask, stir for 30min at a temperature of 80°C and a speed of 150r / min, after the stirring is completed, suction filter, and the filtrate Put it into a dialysis bag and dialyze with distilled water for 3 days to obtain a silk fibroin solution, and dry it at 60°C to obtain silk fibroin B.

[0045] (c) Put 80 mL of citronellol solution into a three-necked flask, add 25 mL of serine solution, 5 mL of 98% concentrated sulfuric acid, and stir for 10 h at 80 °C and 250 r / min. Then at a speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com