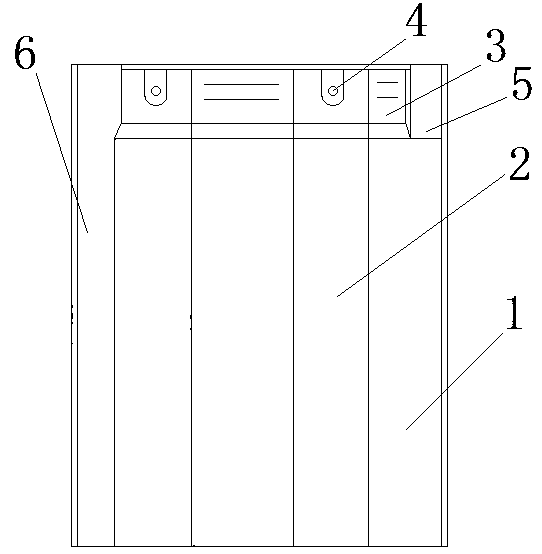

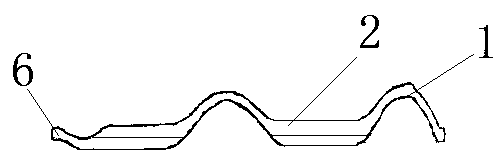

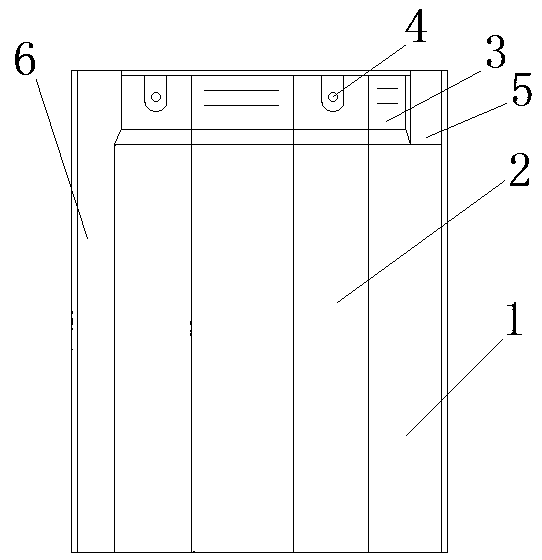

Leak-proof ceramic tile and preparation method thereof

A technology of ceramic tiles and tile heads, which is applied to roofs, roof coverings, buildings, etc. that use tiles/slate tiles. It can solve problems such as cracks, breaks, and poor drainage, and achieve control of deformation and tight lap joints. , Increase the effect of drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The following raw materials are taken by weight: magnesia 18%, Xiangyin mud 10%, Baixiang sand 15%, Xinyang soil 3%, high alumina 8%, Hengyang sand 15%, Fushan sand 14%, waste residue 15% , additive 2%; the above batch materials are obtained by ball milling of raw materials, spray drying, dry pressing of powder materials, drying of green bodies, glazing decoration, and oxidative firing at 1130-1160 degrees;

[0019] The main chemical composition of the obtained ceramic tile is: SiO 2 69.8%, Al 2 o 3 17.2%, CaO 2.8%, MgO 3.2%, K 2 O 3.2%Na 2 O 1.6%, Fe 2 o 3 1.5%, the water absorption rate is 1.0-4.5%, and the breaking strength is greater than 2000N.

Embodiment 2

[0021] The following raw materials are taken by weight: magnesia 12%, Xiangyin mud 15%, Baixiang sand 16%, Xinyang soil 8%, high alumina 5%, Hengyang sand 20%, Fushan sand 16%, waste residue 6% , additive 1.2%; the above batch materials are obtained by ball milling of raw materials, spray drying, powder dry pressing mold molding, green body drying, glaze decoration, and oxidative firing at 1130-1160 degrees;

[0022] Its main chemical composition is: SiO 2 72.3%, Al 2 o 3 14.5%, CaO 2.4%, MgO 2.8%, K 2 O 3.5%, Na 2 O2.2%, Fe 2 o 3 1.9%, the water absorption rate is 1.0-4.5%, and the breaking strength is greater than 2000N.

[0023] The mold of the present invention heightens the drainage groove and the step position of the tile head, strengthens the bottom surface of the flat groove of the mold, the bonding position between the flat groove and the convex peak, and blunts the intersection line between the platform and the flat groove and the junction between the platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com