A kind of nano manganese dioxide sponge and its preparation method and application

A technology of nano-manganese dioxide and manganese dioxide sponge, which is applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc., can solve the problems of difficulty in improving catalytic activity and low loading capacity, and achieve improved catalytic degradation of formaldehyde ability, enhance catalytic activity, and improve catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

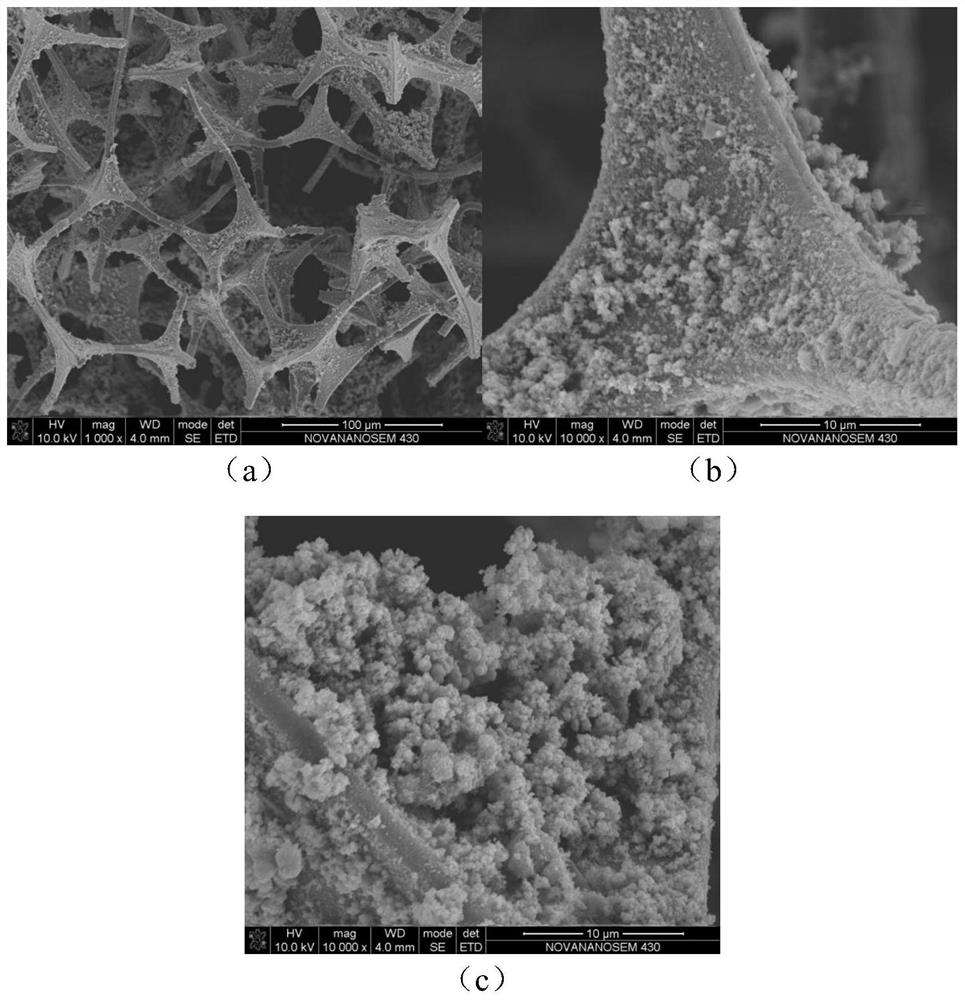

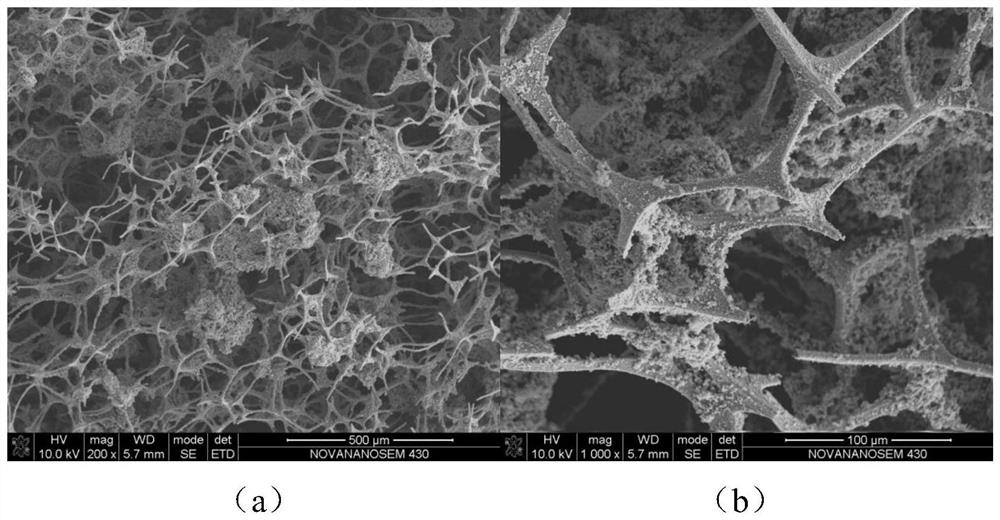

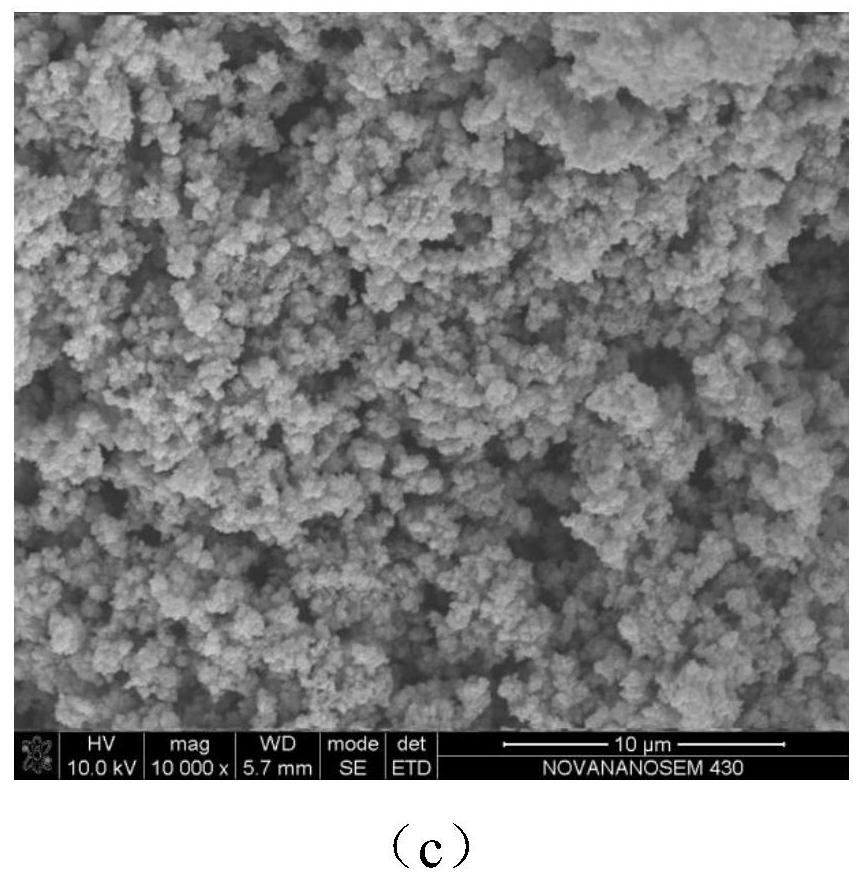

[0038] The melamine nanosponge substrate is ethanol activated and dried. Weigh 3g of potassium permanganate and 5.6g of sodium oxalate into a reaction bottle, add 100ml of distilled water, mix well to obtain a reaction solution Ⅰ, put the nano-sponge cut to a weight of 0.3g into the reaction solution Ⅰ for 20 minutes, and then soak the The final nano-sponge is put into a 50ml reaction kettle I (containing 20ml water), and after 120°C stirring hydrothermal reaction for 4 hours, the nano-manganese dioxide sponge initially grown in situ is obtained. After soaking, the remaining reaction solution II is used again. Liquid II soaked the nano-manganese dioxide sponge initially grown in situ for 20 minutes, and then put it into the 50ml reaction kettle I again, stirred and hydrothermally reacted at 120°C for 7 hours, and then cooled naturally to room temperature. Soak the reacted composite material in deionized water for 30 minutes, pour out the water, repeat the operation 4 times, pu...

Embodiment 2

[0040]The melamine nanosponge substrate is ethanol activated and dried. Weigh 4g of sodium permanganate and 1.6g of potassium oxalate into a reaction bottle, add 150ml of distilled water, mix well to obtain a reaction solution Ⅰ, put the nano-sponge cut to a weight of 0.3g into the reaction solution Ⅰ for 20 minutes, and then soak The final nano-sponge is put into a 50ml reaction kettle I (containing 20ml water), and after 120°C stirring hydrothermal reaction for 4 hours, the nano-manganese dioxide sponge initially grown in situ is obtained. After soaking, the remaining reaction solution II is used again. Liquid II soaked the nano-manganese dioxide sponge initially grown in situ for 20 minutes, and then put it into the 50ml reaction kettle I again, stirred and hydrothermally reacted at 120°C for 7 hours, and then cooled naturally to room temperature. Soak the reacted composite material in deionized water for 30 minutes, pour out the water, repeat the operation 4 times, put it ...

Embodiment 3

[0042] The melamine nanosponge substrate is ethanol activated and dried. Weigh 2g of sodium permanganate, 2g of potassium permanganate, 1g of potassium oxalate, and 1g of ammonium oxalate into a reaction flask, add 150ml of distilled water, mix well to obtain reaction solution I, and put the nano-sponge cut to a weight of 0.3g into the reaction flask. Soak in solution Ⅰ for 20 minutes, then put the soaked nano-sponge into 50ml reaction kettle Ⅰ (containing 20ml water), stir and hydrothermally react at 100°C for 5 hours, and obtain a preliminary in-situ grown nano-manganese dioxide sponge. Finally, the remaining reaction solution II was used to soak the initially in-situ grown nano-manganese dioxide sponge in the reaction solution II again for 20 minutes, and then put it into the 50ml reaction kettle I again, stirred and hydrothermally reacted at 100°C for 5 hours, and then cooled naturally to room temperature. Soak the reacted composite material in distilled water for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com