Preparation method of abrasion resistant layer of stripping die device

A wear-resistant layer and die head technology, which is applied in the production and processing field of peeling die devices, can solve the problems of polluting the environment and easily corroding the skin of operators, and achieves the effects of high stress strength, improved peeling quality and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

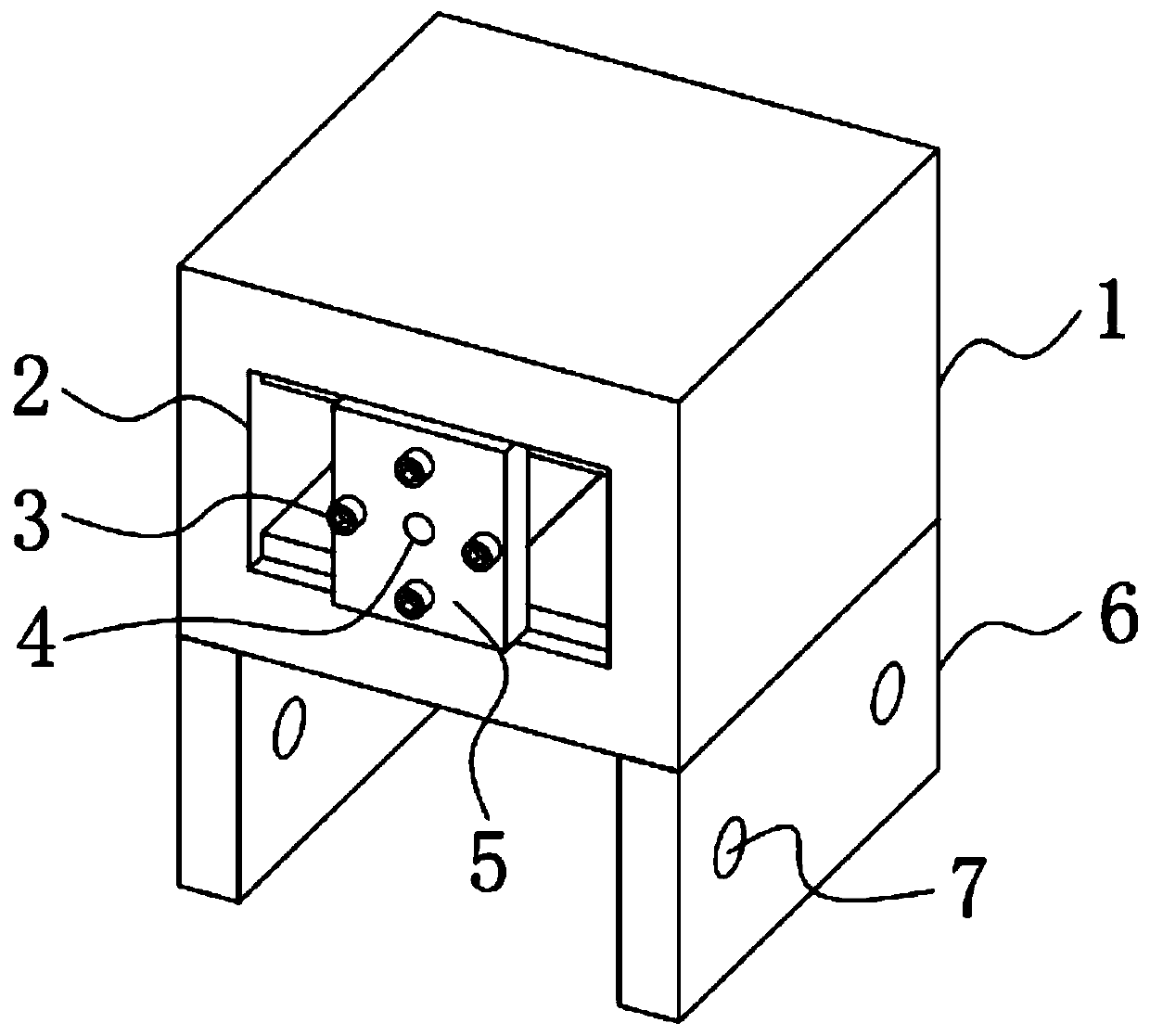

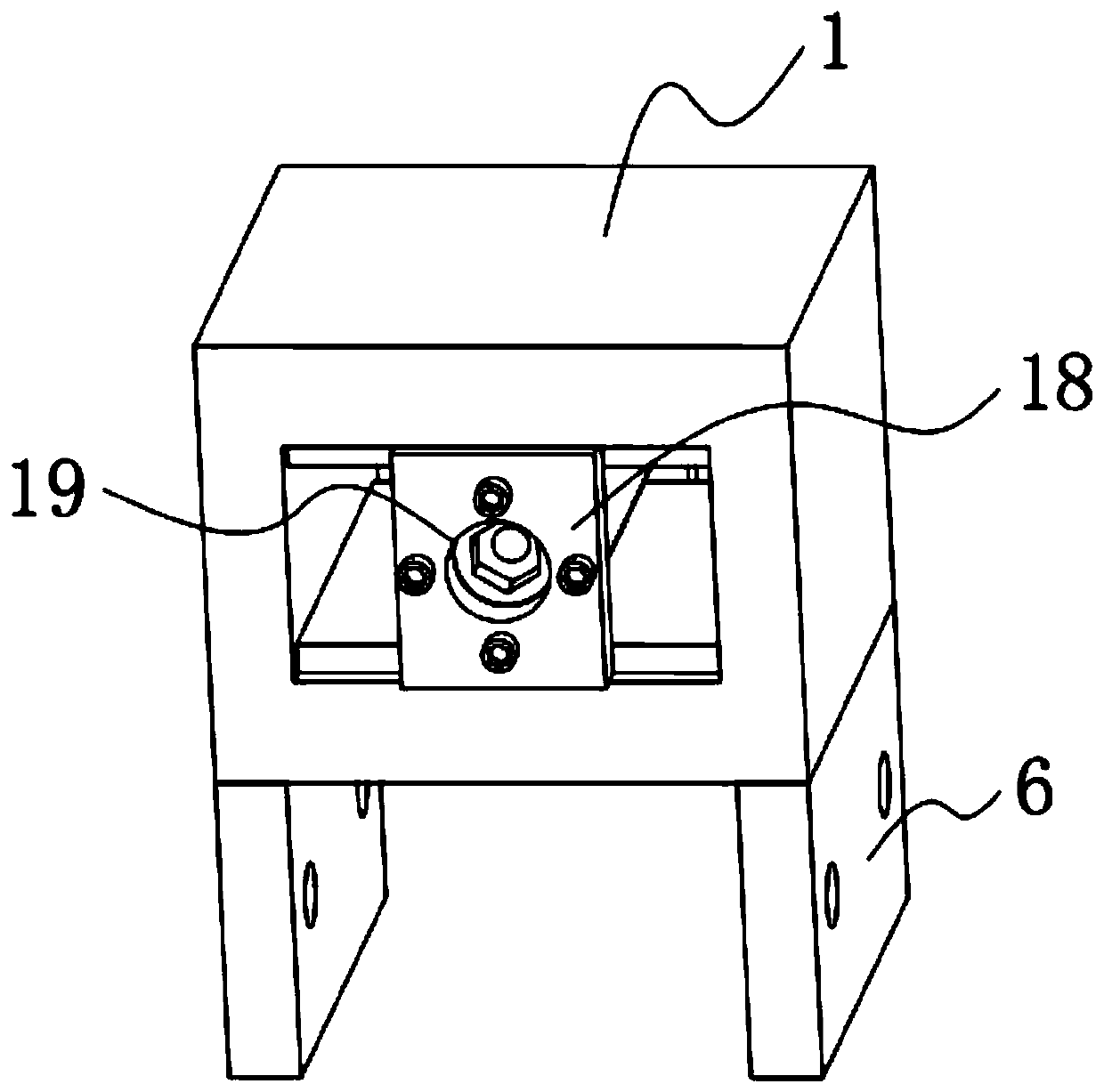

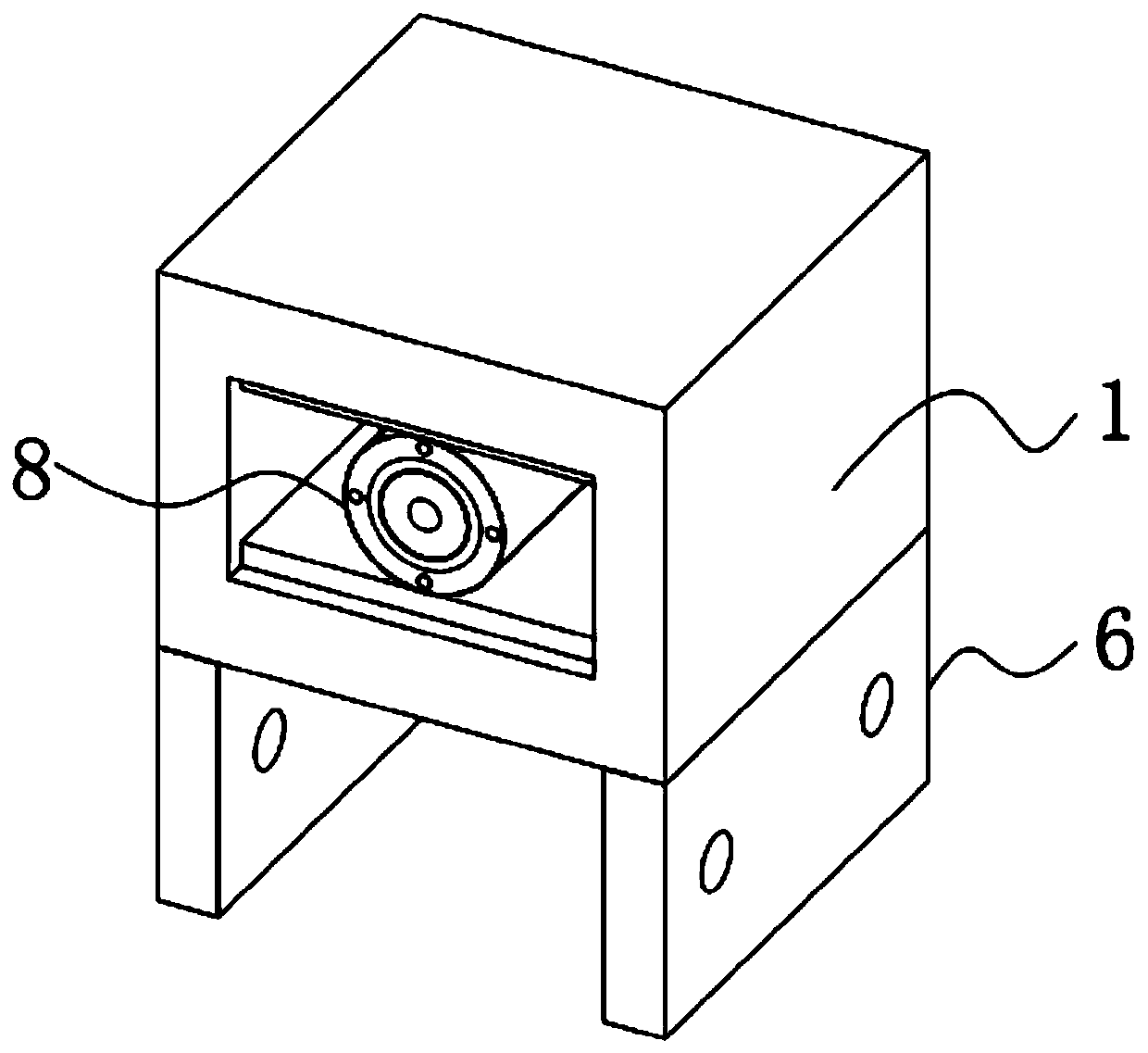

[0053] The following is attached Figure 1-12 The present invention is described in further detail.

[0054] A peeling die device for aluminum welding wire production, such as Figure 1-12 As shown, the installation seat 1 is included, and the inside of the installation seat 1 is provided with a through groove 2, and the inside of the through groove 2 is movably installed with a rolling bearing 8, and the inside of the rolling bearing 8 is fixedly installed with an inner core 10. The inside of the core 10 is movably installed with a die head 11 near one end thereof, and the inside of the inner core 10 is screwed with a top core 13 for tightening the die head 11 near the other end thereof, and the through groove 2 Two limit grooves 17 are symmetrically opened at both ends, and a first end cover 5 and a second end cover 18 that can move laterally along the two limit grooves 17 are installed respectively, and the first end cover 5 is fixedly connected to one end of the rolling ...

Embodiment 2

[0063] The difference from Example 1 is that the inner surface of the welding wire inlet 4, the inner surface of the knife edge 12 and the inner surface of the welding wire channel 15 are all provided with a wear-resistant layer, and the wear-resistant layer is prepared by the following method :

[0064] Take the following raw materials and weigh them by weight: 20 parts of polytetrafluoroethylene, 6 parts of bronze powder, 5 parts of ceramic powder, 15 parts of aluminum oxide powder, 10 parts of chromium oxide particles, 4 parts of film-forming aids, 2 parts of joint agent, 3 parts of defoamer, 2 parts of leveling agent and 40 parts of methanol;

[0065] S1, adding polytetrafluoroethylene, bronze powder, ceramic powder, aluminum oxide powder and chromium oxide particles into a ball mill for fine grinding to obtain a mixed powder material;

[0066] S2. Add the mixed powder material and methanol prepared in step S1 into the reaction kettle and stir for 20 minutes, then add fil...

Embodiment 3

[0073] The difference from Example 2 is the preparation of the wear-resistant layer, and its specific preparation method is as follows:

[0074] Take the following raw materials and weigh them by weight: 25 parts of polytetrafluoroethylene, 8 parts of bronze powder, 7 parts of ceramic powder, 20 parts of aluminum oxide powder, 13 parts of chromium oxide particles, 5 parts of film-forming aids, 4 parts of joint agent, 4 parts of defoamer, 3 parts of leveling agent and 50 parts of methanol;

[0075] S1, adding polytetrafluoroethylene, bronze powder, ceramic powder, aluminum oxide powder and chromium oxide particles into a ball mill for fine grinding to obtain a mixed powder material;

[0076] S2. Add the mixed powder material and methanol prepared in step S1 into the reaction kettle and stir for 25 minutes, then add film-forming aids, coupling agents, defoamers and leveling agents, and continue stirring for 30 minutes, and the stirring speed is set to 800r / min, the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com