Bevel sewing machine and rigid sewing wire mesh weaving reinforced heat preservation board manufactured by same

A sewing machine and thermal insulation board technology, which is applied in the field of building thermal insulation materials, can solve problems such as the inability to lift the thermal insulation board to the downward gravity, the peeling off of the external wall thermal insulation layer and the decorative layer, and weak compression and tensile resistance. , to achieve the effects of reducing wind tunnel gaps, enhancing thermal insulation effect, increasing negative wind pressure and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

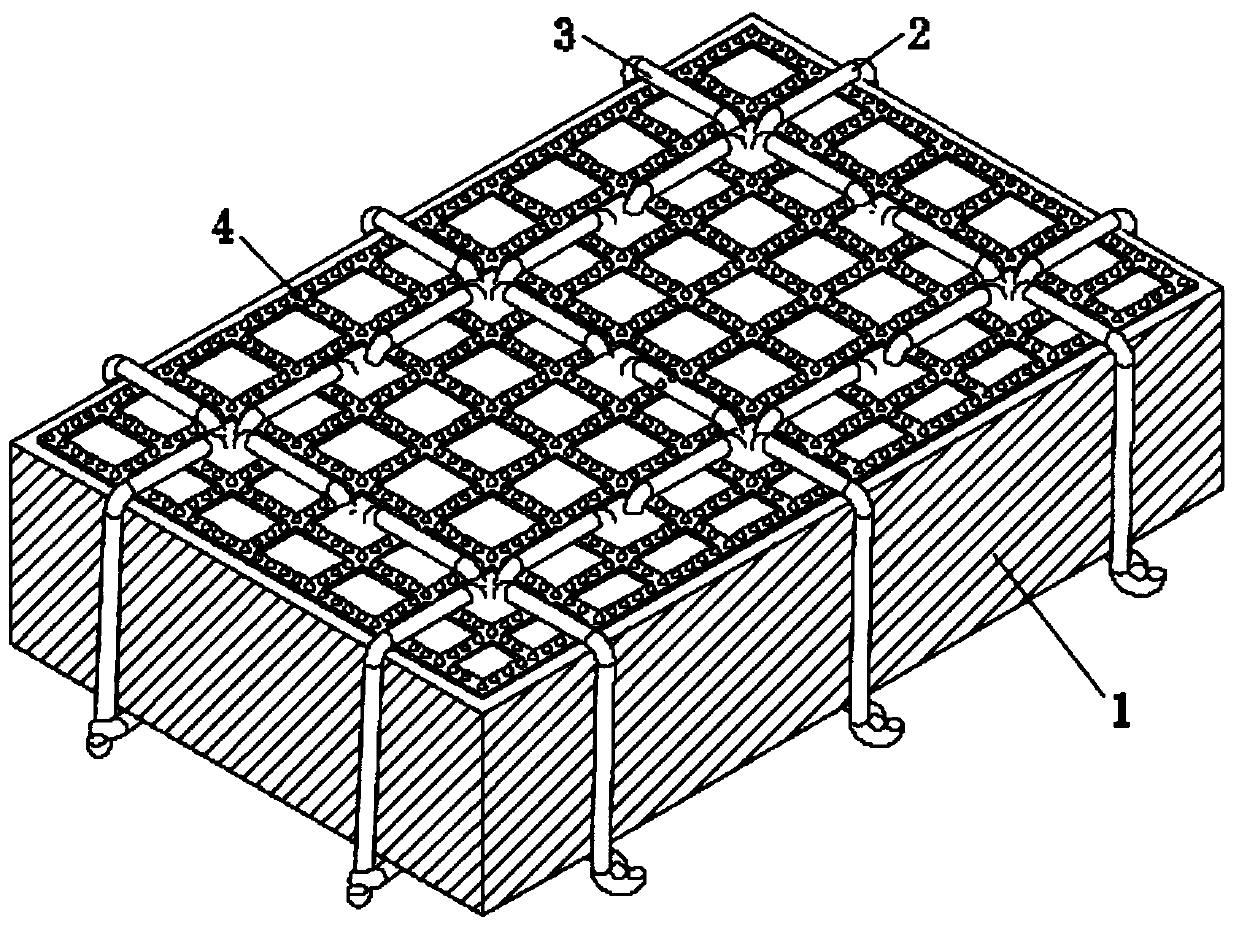

[0048] see figure 1 and figure 2 , a rigid suture thread mesh reinforced thermal insulation board made based on the inclined suture machine, comprising a board body 1, two radial suture lines 2, and three latitudinal suture lines 3. The radial stitching thread 2 and the latitudinal stitching thread 3 interweave each other, and the radial stitching thread 2 and the latitudinal stitching thread 3 are vertically distributed in the plate body 1, and the radial stitching thread 2 and the latitudinal seam The binding wires 3 interweave to form a spatial rectangular grid structure, such as image 3 shown.

[0049] In this embodiment, the radial stitching thread 2 and the latitudinal stitching thread 3 are fiberglass wire rods formed by dipping synthetic resin and curing. One or more of glass fiber, carbon fiber, aramid fiber or basalt fiber can be selected as the fiber line. Liquid polymers are thermosetting synthetic resins, such as unsaturated polyesters, phenolic resins, and ...

Embodiment 2

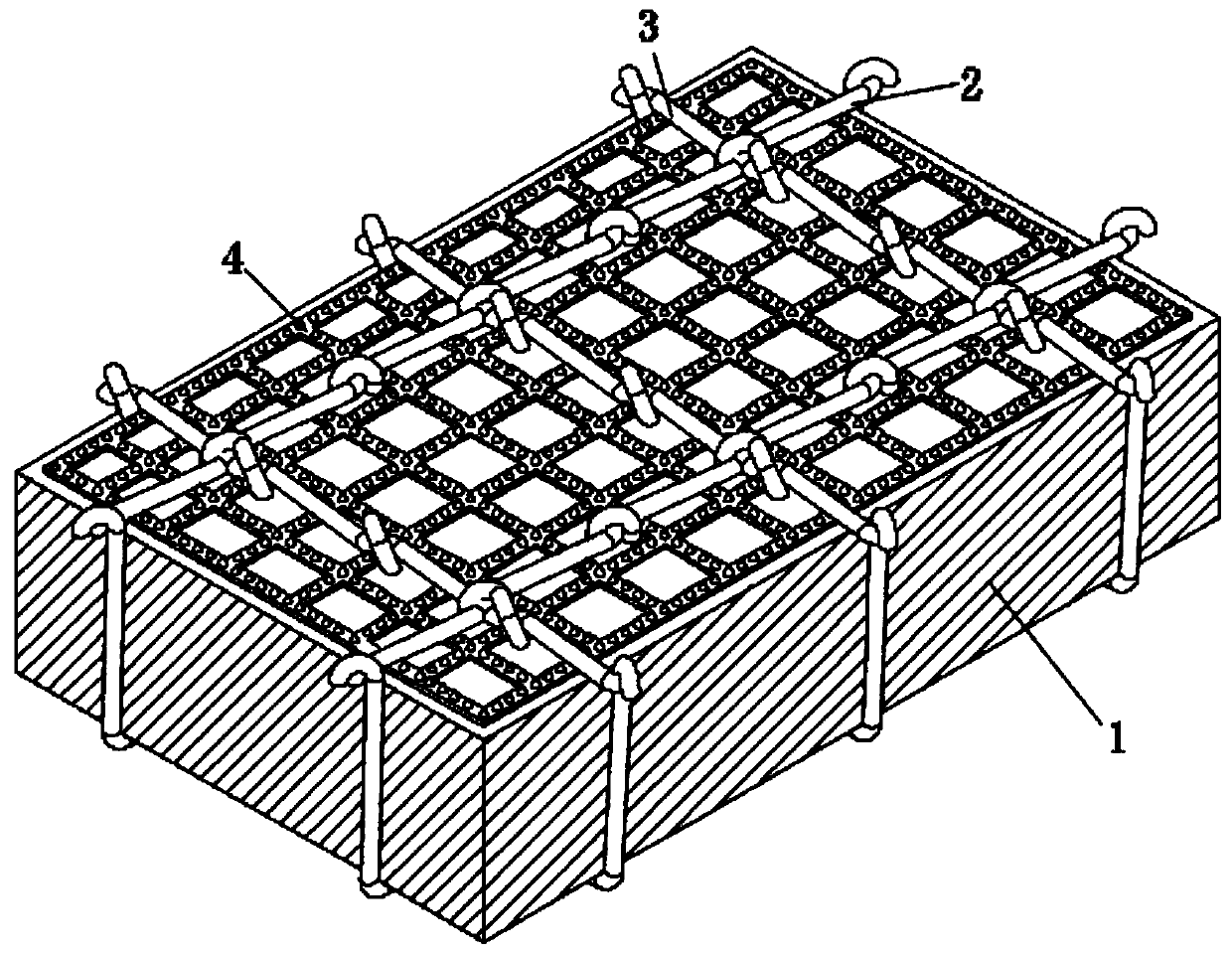

[0064] The difference between the technical features of this embodiment and the technical features of Embodiment 1 is that the radial suturing lines 2 are vertically distributed in the plate body 1, the latitudinal suturing lines 3 are distributed obliquely in the plate body 1, and the radial suturing lines 2 are distributed vertically in the plate body 1. Thread 2 and weft stitching thread 3 interweave to form a spatial rectangular grid structure, such as Figure 4 shown.

[0065] The suturing intersection of the radial suturing thread 2 and the weft suturing thread 3 is in the shape of a "V" in the plate body 1, and the included angle of the "V" shape is 70°-30°, and the "V" shape The two side lines and the surface of the insulation board form a right triangle shape. When the insulation board is constructed on the wall, the "V" shape and the wall form a right triangle structure. According to the principle of the triangular chord and the case of the cable bridge, the use of ...

Embodiment 3

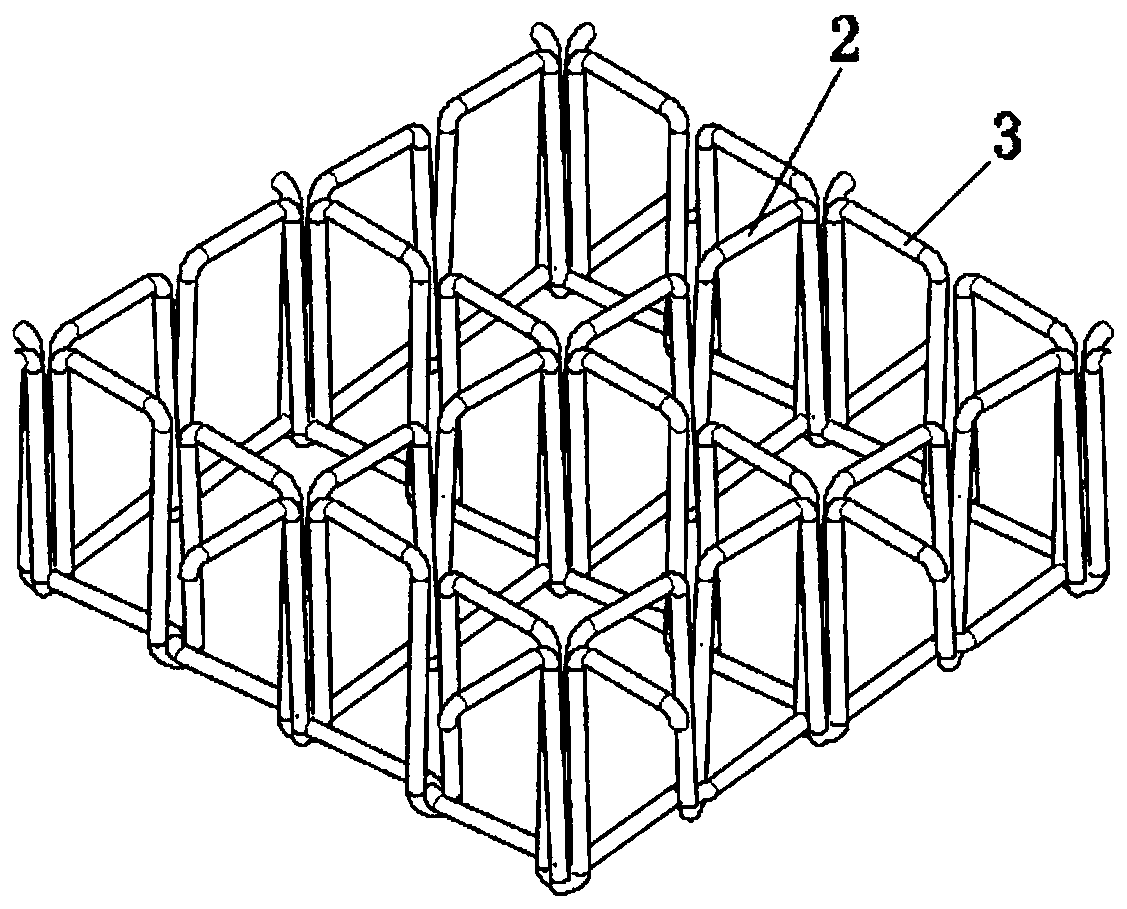

[0074] The difference between the technical features of this embodiment and the technical features of Embodiment 1 and Embodiment 2 is that the radial sutures 2 and the latitudinal sutures 3 are distributed obliquely in the plate body 1, and the inclination angles are both 7° °—30°, the radial stitching thread 2 and the latitudinal stitching thread 3 interweave and form a "V" shape obliquely distributed at the intersection of the stitching, and the two side lines of the "V" shape are in contact with the surface of the insulation board form a triangle shape. The suture space frame structure formed by this suture method is as follows: Figure 5 shown.

[0075] All the other features are the same as those in Embodiment 1 and Embodiment 2.

[0076]The difference between the stitching process of the thermal insulation board in this embodiment and the second embodiment is that in step (4), the radial stitching needle 61 used for radial oblique piercing stitching is vertical downwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com