Ceramsite sand and production process thereof

A technology of ceramsite sand and ceramsite, which is applied in the field of ceramsite sand, can solve the problems that the mullite crystal phase cannot be uniformly distributed, the mullite crystal phase cannot be formed, and the performance of the ceramsite sand is affected, so as to increase the compactness , reduce density, improve roundness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

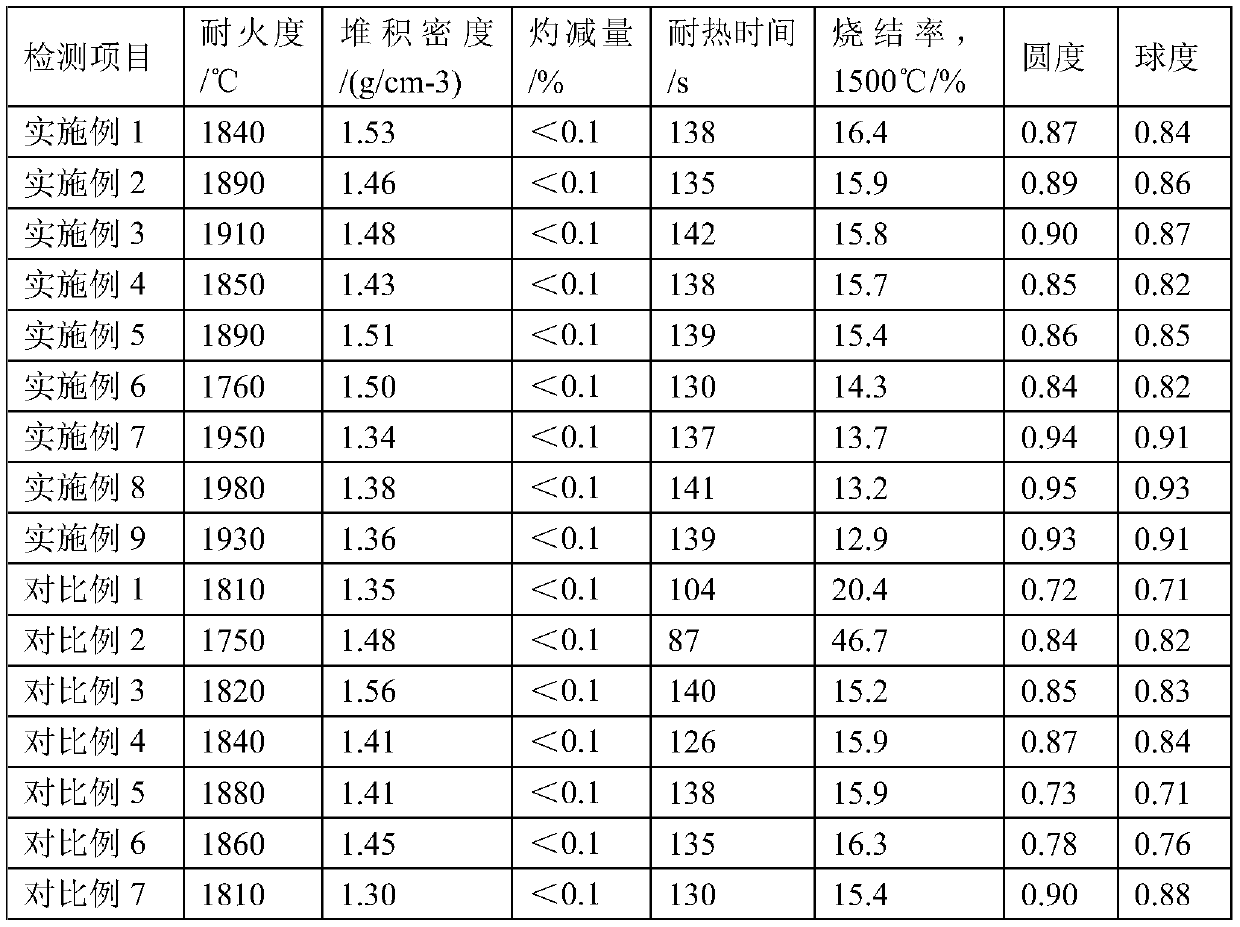

Examples

Embodiment 1

[0043] A kind of ceramsite sand, its raw material ratio is shown in Table 1;

[0044] (1) Coarse crushing, fine crushing, and cone crushing of coal gangue, mullite, kaolin, and bauxite, respectively, for standby;

[0045] (2) Mix the coal gangue, mullite, kaolin, and bauxite after cone crushing evenly, and carry out ball milling and powder selection to obtain a raw material mixture;

[0046] (3) making the water form atomized water, and adding the atomized water into the raw material mixture to granulate, the amount of water added is 5% of the total weight of the raw material mixture, and then sieving to obtain a semi-finished product;

[0047] (4) heat preservation at 120°C for 1h, then roast at 1000°C for 1h, then roast at 1300°C for 1h, cool down and sieve to obtain the ceramsite body, That is, the ceramsite sand is obtained, and the particle size of the ceramsite sand is a continuous particle size of 7-14 mm.

[0048]Among them, the granulation is prepared by the followi...

Embodiment 2

[0050] A kind of ceramsite sand, its raw material ratio is shown in Table 1;

[0051] (1) Coarse crushing, fine crushing, and cone crushing of coal gangue, mullite, kaolin, and bauxite, respectively, for standby;

[0052] (2) Mix the coal gangue, mullite, kaolin, and bauxite after cone crushing evenly, and carry out ball milling and powder selection to obtain a raw material mixture;

[0053] (3) making the water form atomized water, and adding the atomized water into the raw material mixture for granulation, the amount of water added is 12% of the total weight of the raw material mixture, and then sieving to obtain a semi-finished product;

[0054] (4) Keep the temperature at 112°C for 1.7h, then at 930°C for 1.3h, then at 1230°C for 1.2h, cool down and sieve to obtain the pottery Grain body, that is, get ceramsite sand, the particle size of ceramsite sand is a continuous particle size of 2-4mm.

[0055] Among them, the granulation is prepared by the following method: the wa...

Embodiment 3

[0057] A kind of ceramsite sand, its raw material ratio is shown in Table 1;

[0058] (1) Coarse crushing, fine crushing, and cone crushing of coal gangue, mullite, kaolin, and bauxite, respectively, for standby;

[0059] (2) Mix the coal gangue, mullite, kaolin, and bauxite after cone crushing evenly, and carry out ball milling and powder selection to obtain a raw material mixture;

[0060] (3) Make the water form atomized water, and add the atomized water into the raw material mixture for granulation, the amount of water added is 10% of the total weight of the raw material mixture, and then sieve to obtain a semi-finished product;

[0061] (4) Under the condition of 115°C, heat preservation for 1.5h, then under the condition of 950°C, roast for 1.5h, then under the condition of 1250°C, roast for 1.5h, cool down and sieve to obtain the pottery Grain body, that is to get ceramsite sand, the particle size of ceramsite sand is a continuous particle size of 4-7mm.

[0062] Amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com