Acoustic package material made of polyurethane-epoxy resin interpenetrating polymer network (IPN) foams and preparation method thereof

An epoxy resin and interpenetrating network technology, applied in the field of acoustic packaging materials, can solve the problems of poor low-frequency sound absorption and high low-frequency sound absorption coefficient, achieve good low-frequency sound absorption performance, improve flexibility, and solve the problem of harsh reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

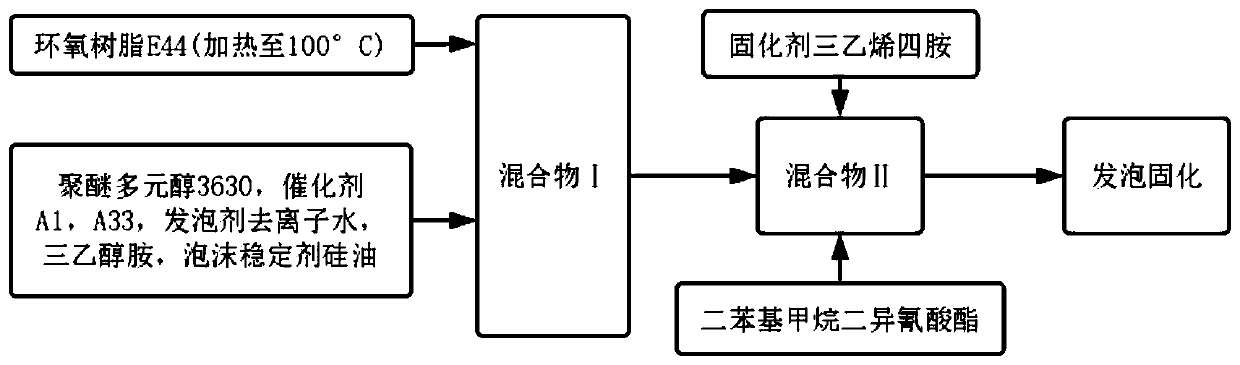

[0039] Such as figure 1 Shown, the present invention also provides a kind of preparation method of polyurethane epoxy resin interpenetrating network foam acoustic packaging material, comprises the steps:

[0040] Step 1. Put the epoxy resin in an incubator and heat it to 100 degrees Celsius to make the epoxy resin change from a highly viscous state to a thin liquid state.

[0041] Step 2, adding the polyether polyol, the first foaming agent, the second foaming agent, the first catalyst, the second catalyst and the foam stabilizer into the heated epoxy resin, and stirring to obtain the first mixture;

[0042] Wherein, the first foaming agent adopts deionized water; the second foaming agent adopts triethanolamine; the first catalyst adopts N,N-dimethyl ethyl ether (catalyst A1), and the second A triethylenediamine solution (catalyst A33) with a mass fraction of 33% was used as the catalyst; silicone oil was used as the foam stabilizer.

[0043] Step 3, adding the curing agent ...

Embodiment 1

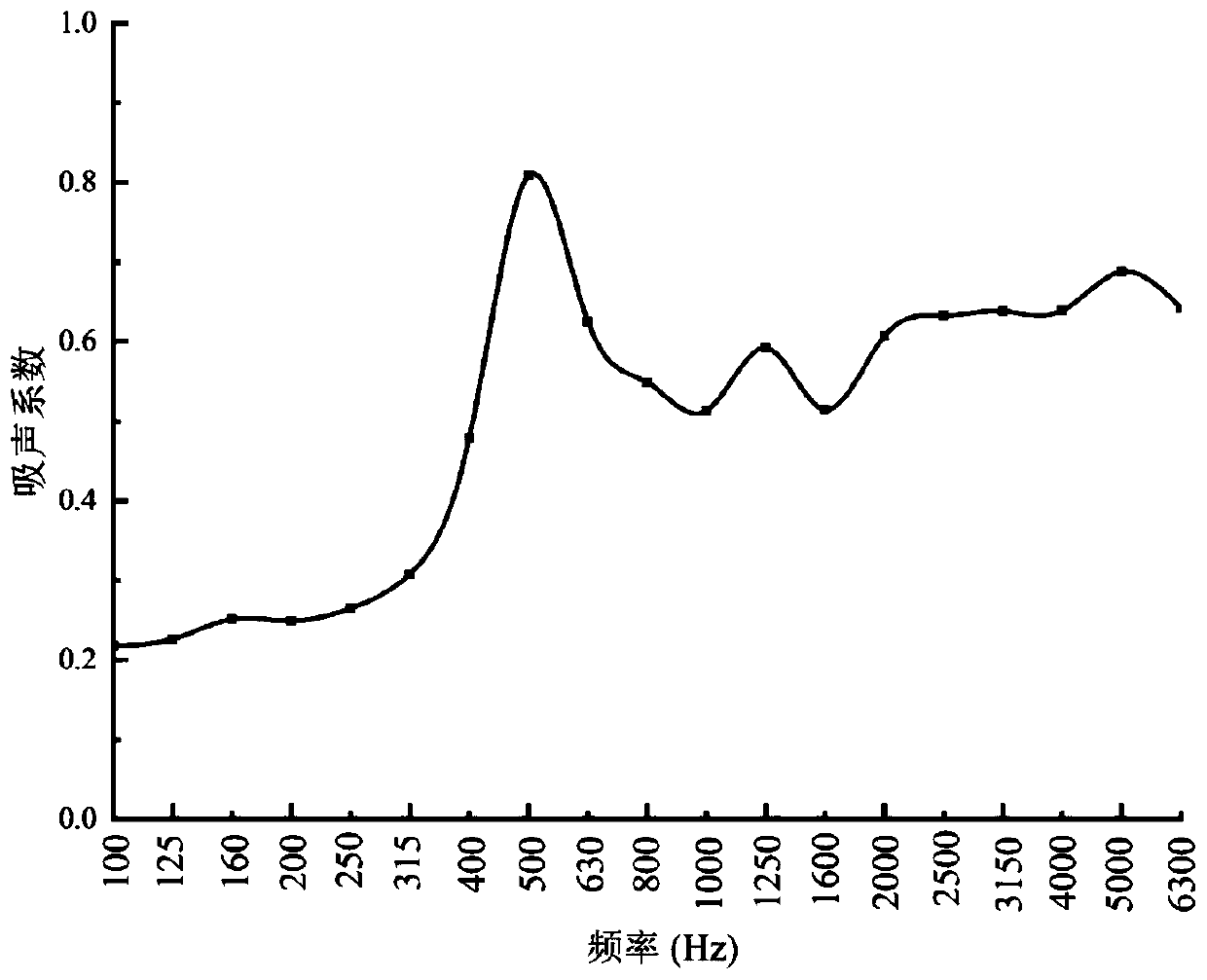

[0051] The preparation process of polyurethane epoxy resin interpenetrating network foam acoustic material is as follows:

[0052](1) 60 grams of epoxy resin E44 are placed in an incubator and heated to 100 degrees Celsius to make epoxy resin E44 change from a viscous very large state to a thin liquid state;

[0053] (2) The epoxy resin E44 obtained in (1) is placed in a paper cup, 40 grams of polyether polyol 3630, 3 grams of foaming agent (deionized water), 3 grams of foaming agent (triethanolamine), 0.35 grams Add catalyst A1, 1 g of catalyst A33, and 1.8 g of foam stabilizer (silicone oil) into a paper cup, mix with epoxy resin E44, and stir with an electric mixer at a speed of 1200 rpm at room temperature. After stirring for 3 to 5 minutes, mixture I is obtained;

[0054] (3) Add 2 grams of curing agent (triethylenetetramine) and 30 grams of diphenylmethane diisocyanate to the mixture I obtained in (2), and then use an electric mixer to stir rapidly and fully at a speed o...

Embodiment 2

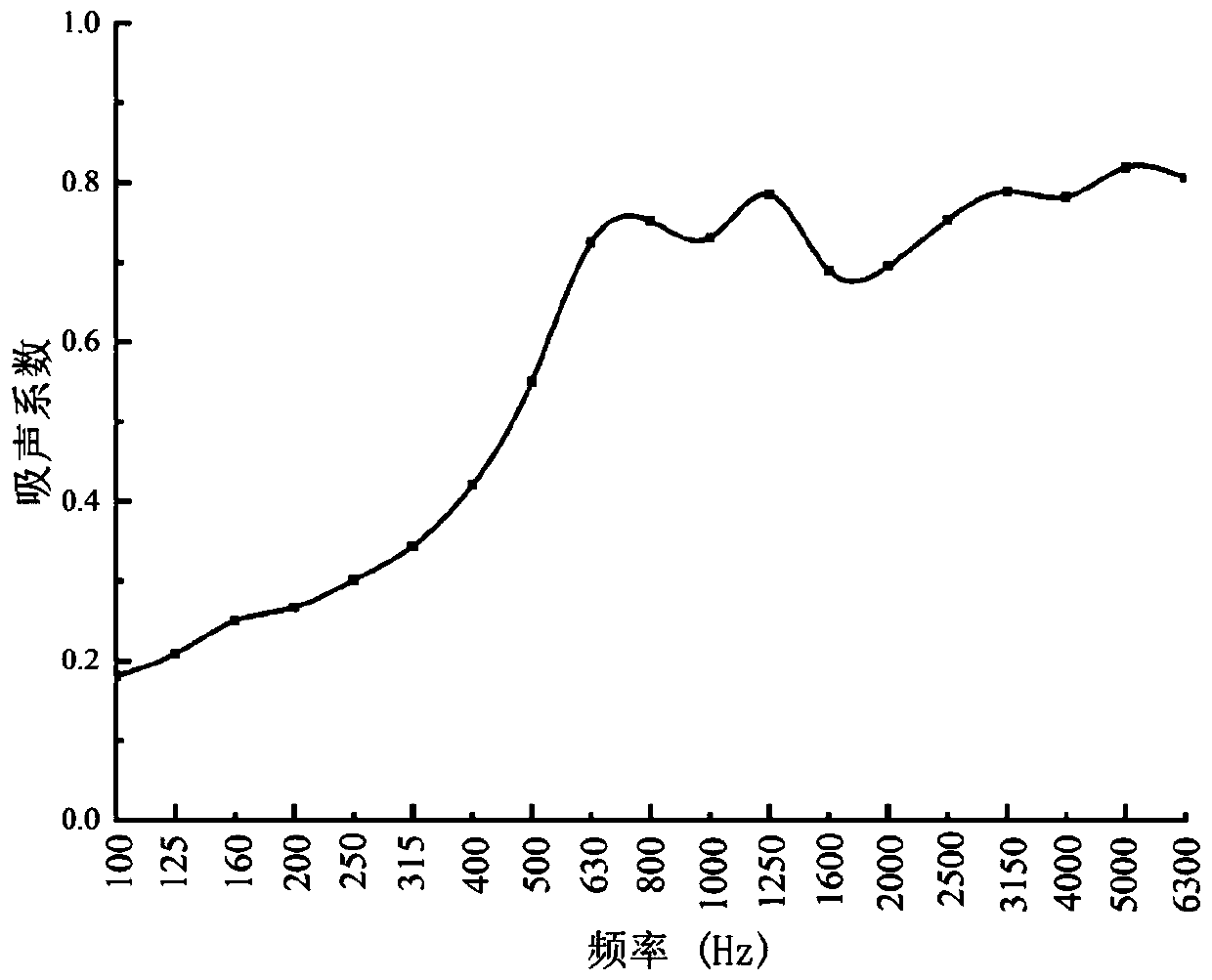

[0058] The preparation process of polyurethane epoxy resin interpenetrating network foam acoustic material is as follows:

[0059] (1) 50 grams of epoxy resin E44 are placed in an incubator and heated to 100 degrees Celsius to make epoxy resin E44 change from a viscous state to a thin liquid state;

[0060] (2) The epoxy resin E44 obtained in (1) is placed in a paper cup, 50 grams of polyether polyol 3630, 2.5 grams of foaming agent (deionized water), 2.5 grams of foaming agent (triethanolamine), 0.5 grams Catalyst A1, 2 grams of catalyst A33, and 1.8 grams of foam stabilizer (silicone oil) were added to a paper cup, mixed with epoxy resin E44, stirred at room temperature with an electric mixer at a speed of 1200 rpm, and stirred for 3 to 5 minutes to obtain mixture I;

[0061] (3) Add 1 gram of curing agent (triethylenetetramine) and 35 grams of diphenylmethane diisocyanate into the mixture I obtained in (2), and then use an electric mixer to stir rapidly and fully at a speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com