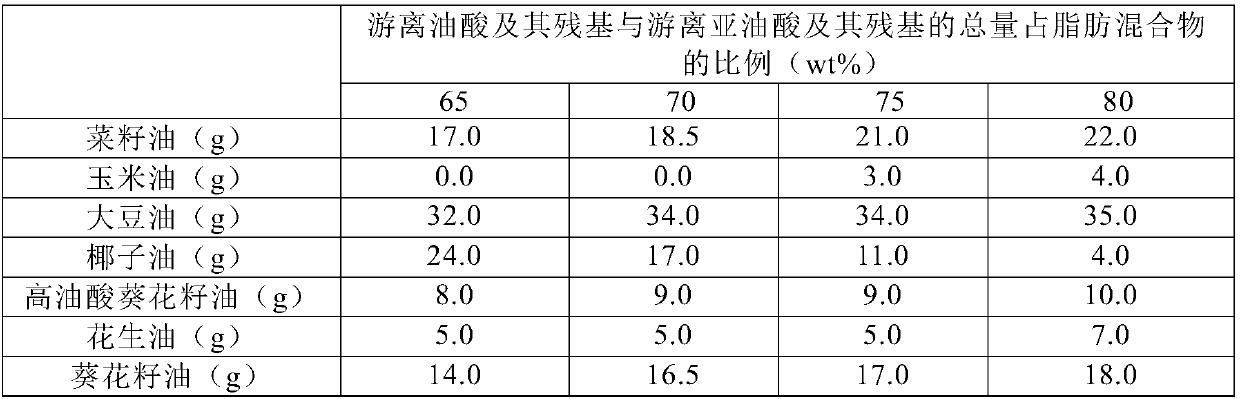

Grease composition and preparation method thereof

A technology for oil composition and fat mixture, which is applied in the fields of edible oil/fat, food science, application, etc., and can solve problems such as inability to be widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

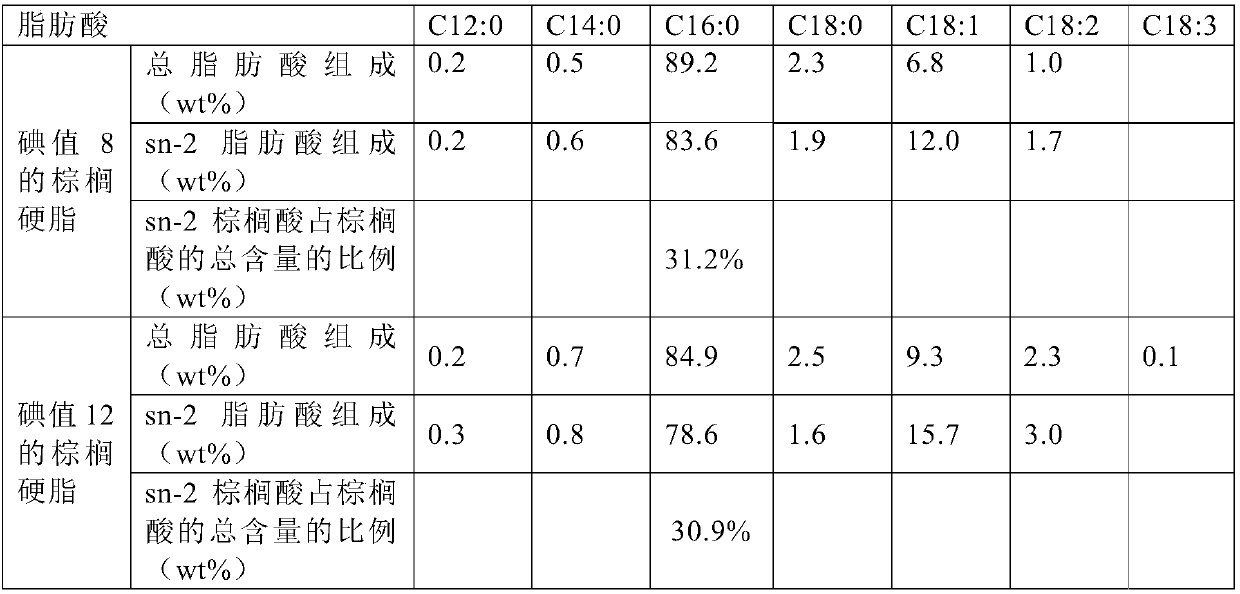

[0064] In another aspect, the present invention provides the preparation method of above-mentioned grease composition, described method comprises the steps:

[0065] (i) provide palm stearin with an iodine value of 8-12;

[0066] (ii) in the presence of a catalyst for enzymatic transesterification, a fatty mixture of palm stearin with an iodine value of 8-12 and oleic acid or its non-glycerides and linoleic acid or its non-glycerides is subjected to Sn-1, 3 directional transesterification, so as to obtain the grease A through transesterification,

[0067] wherein said fat mixture is prepared from oleic acid or its non-glycerides and linoleic acid or its non-glycerides, or from fats and oils as sources of oleic acid or its non-glycerides and linoleic acid or its non-glycerides,

[0068] Wherein, relative to the total weight of the fat mixture, the total amount of free oleic acid and its residues and free linoleic acid and its residues accounts for more than 70 wt%, preferably ...

Embodiment 1

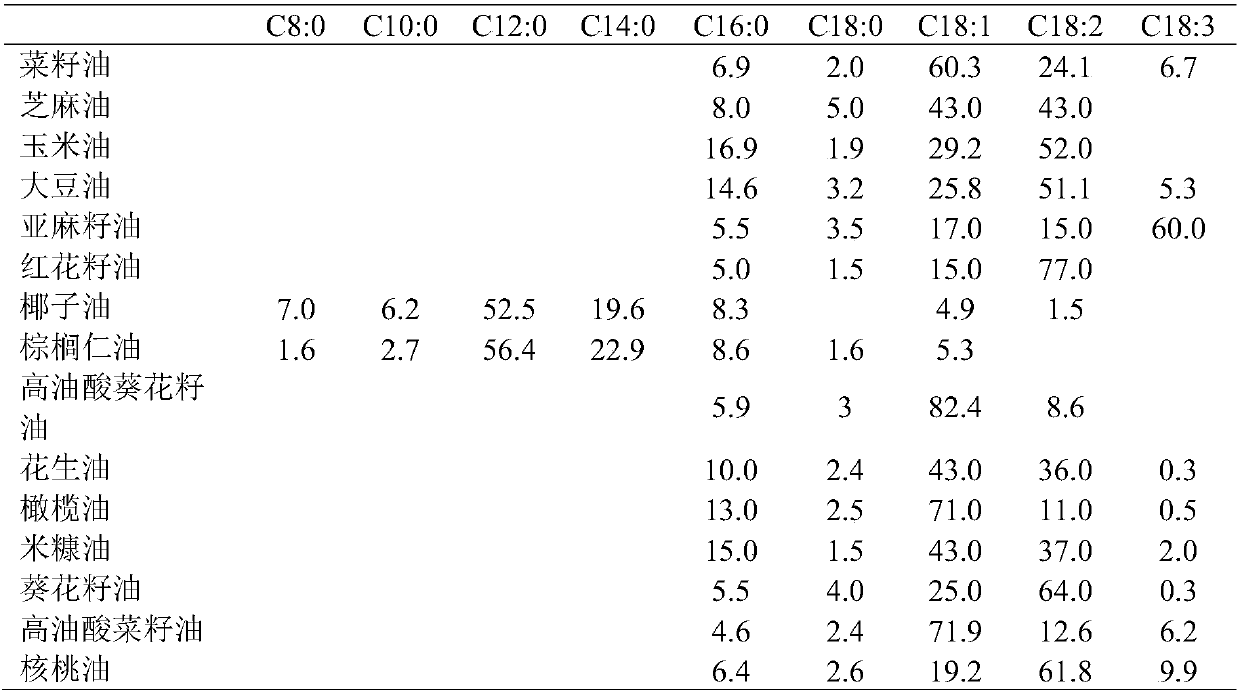

[0102] Example 1: Using fat mixtures with different ratios of oleic acid to linoleic acid to prepare the target oil composition

[0103] At room temperature, prepare the fat mixture according to the ratio shown in Table 3 below. After mixing, add 30ml of hydrochloric acid (2mol / L), heat in a water bath at 80°C for 50min, and hydrolyze to obtain fatty acid or non-glyceride ester of fatty acid. After the reaction, 100 ml of n-hexane was added to extract the hydrolyzate, the solvent was removed by a rotary evaporator, and dried to obtain four groups of fat mixtures. Wherein, the proportions of the total amount of free oleic acid and its residues and free linoleic acid and its residues to the total weight of the fat mixture are 65wt%, 70wt%, 75wt% and 80wt%, and free oleic acid and its residues The ratio to free linoleic acid and its residues is 1:1.

[0104] Table 3 Composition of vegetable oil in fat mixture

[0105]

[0106] 100 g of palm stearin with an iodine value of 10...

Embodiment 2

[0109] Embodiment 2: the fatty acid preparation target oil composition of the ratio of the total amount of free oleic acid and its residues and the total amount of free linoleic acid and its residues

[0110] At room temperature, the mixture was prepared according to the composition of the fat mixture shown in Table 5, and the mixture was hydrolyzed and extracted according to the method described in Example 1 to obtain four groups of fat mixtures. Wherein, the ratio of the total amount of free oleic acid and its residues to the total amount of free linoleic acid and its residues in the prepared fat mixture is 0.5:1, 1:1, 1.5:1, 2:1, 2.5 : 1 (in weight ratio), the total amount of free oleic acid and residues thereof and free linoleic acid and residues thereof accounts for 80wt% of the total weight of the fat mixture.

[0111] Table 5 Composition of vegetable oil in fat mixture

[0112]

[0113] 100 g of palm stearin with an iodine value of 10 was weighed and placed in a 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com