Formula feed for improving stress resistance of laying hens

A compound feed and anti-stress technology, applied in the field of feed, can solve the problems of thin egg white, poor taste and nutritional value, short storage time and easy to deteriorate, so as to promote digestion and absorption, reduce crushing and suffocation, and improve intestinal tract The effect of mucosal absorption function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

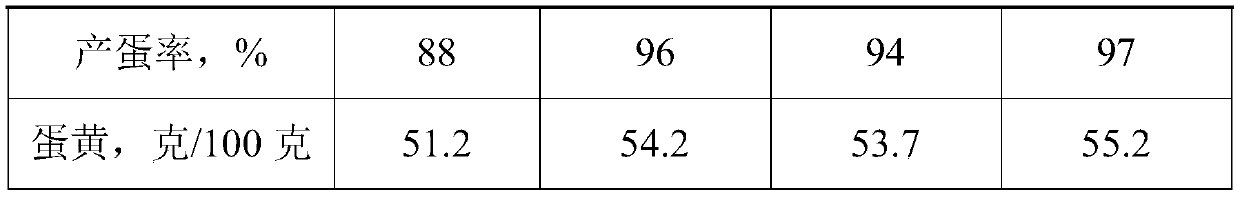

Examples

Embodiment 1

[0024] An additive, calculated in parts by weight, includes the following raw materials:

[0025] 50 parts of lemon peel extract, 32 parts of tea leaves, 12 parts of pig liver and 2 parts of compound enzyme. The compound enzyme is a mixed enzyme of cellulase and neutral protease.

[0026] Lemon peel extract is prepared by the following method:

[0027] Add lemon peel to water for boiling treatment, the boiling time is 20min, then cool to 40°C, beating, then add amylase for enzymatic hydrolysis, the enzymatic hydrolysis time is 3h, then heat up and inactivate, filter, and concentrate the filtrate at low temperature Dried to obtain lemon peel extract. The addition of amylase is 0.5% of lemon peel weight.

[0028] The preparation method of additive, comprises the following steps:

[0029] 1) beating: mixing the tea leaves and pork liver for beating to obtain a slurry;

[0030] 2) Enzymolysis: heat the slurry to 60°C, then add compound enzymes, enzymolyze for 2 hours, then he...

Embodiment 2

[0032] An additive, calculated in parts by weight, includes the following raw materials:

[0033] 60 parts of lemon peel extract, 30 parts of tea leaves, 6 parts of pig liver and 5 parts of compound enzyme. The compound enzyme is a mixed enzyme of cellulase and neutral protease.

[0034] Lemon peel extract is prepared by the following method:

[0035] Add lemon peel into water for boiling treatment, the boiling time is 30min, then cool to 60°C, beating, then add amylase for enzymolysis, the enzymolysis time is 1h, then heat up and inactivate, filter, and concentrate the filtrate at low temperature Dried to obtain lemon peel extract. The addition of amylase is 0.9% of lemon peel weight.

[0036] The preparation method of additive, comprises the following steps:

[0037] 1) beating: mixing the tea leaves and pork liver for beating to obtain a slurry;

[0038] 2) Enzymolysis: heat the slurry to 54°C, then add complex enzymes, enzymolyze for 3 hours, then heat up and inactiva...

Embodiment 3

[0040] An additive, calculated in parts by weight, includes the following raw materials:

[0041] 54 parts of lemon peel extract, 40 parts of tea leaves, 8 parts of pig liver and 6 parts of compound enzyme. The compound enzyme is a mixed enzyme of cellulase and neutral protease.

[0042] Lemon peel extract is prepared by the following method:

[0043] Add lemon peel to water for boiling treatment, the boiling time is 23min, then cool to 46°C, beating, then add amylase for enzymolysis, the enzymolysis time is 3h, then heat up and inactivate, filter, and concentrate the filtrate at low temperature Dried to obtain lemon peel extract. The addition of amylase is 1.1% of the weight of the lemon peel.

[0044] The preparation method of additive, comprises the following steps:

[0045] 1) beating: mixing the tea leaves and pork liver for beating to obtain a slurry;

[0046] 2) Enzymolysis: heat the slurry to 55°C, then add complex enzymes, enzymolyze for 3 hours, then heat up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com