An environmentally friendly easy -to -skip bearing rust -proof oil and its preparation method

An environment-friendly, anti-rust oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problem that the degreasing property of the anti-rust oil needs to be improved, and achieve the effect of safe use, good degreasing performance and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

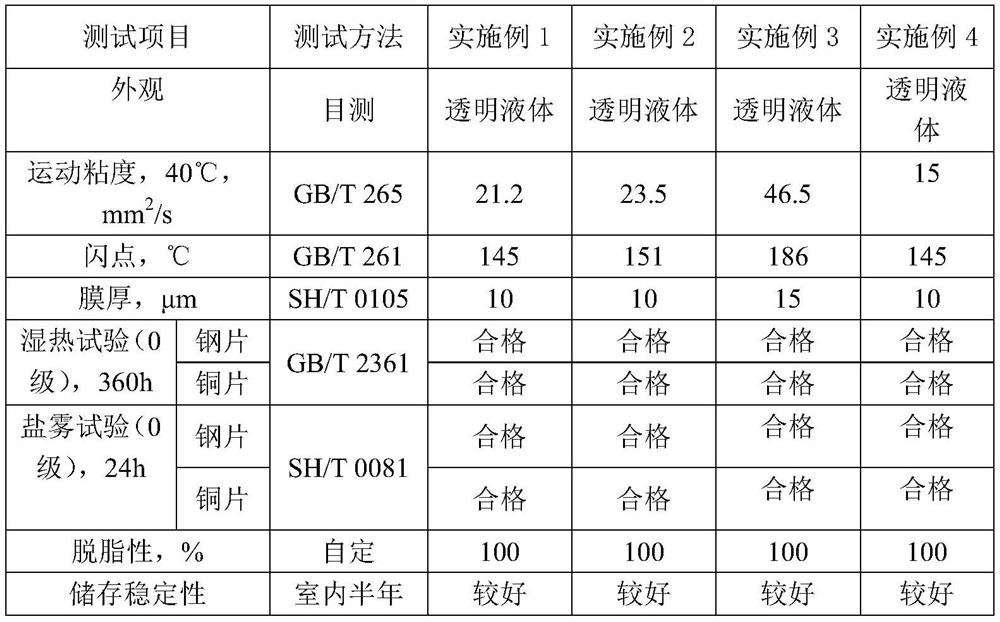

Examples

Embodiment 1

[0030] The environment-friendly easy degreasing bearing antirust oil of the present embodiment is made up of the following components of weight: No. 25 transformer oil 885kg, calcium dinonyl naphthalene sulfonate 40kg, petroleum calcium sulfonate 40kg, 10kg Span-80, lanolin fatty acid Pentaerythritol ester 20kg, methyl benzotriazole 5kg.

[0031] The preparation method of the environment-friendly easy degreasing bearing antirust oil of the present embodiment comprises the following steps:

[0032] 1) Add 885kg of No. 25 transformer oil into the blending kettle, heat it to 110°C, and then keep stirring. At the same time, add 40kg of calcium dinonylnaphthalene sulfonate and 40kg of calcium petroleum sulfonate, and stir for 1 hour at this temperature. Dinonylnaphthalene calcium sulfonate and calcium petroleum sulfonate are completely dissolved to obtain a premix;

[0033] 2) Cool the pre-mixture in step 1) to 90°C, add 20kg lanolin fatty acid pentaerythritol ester, 10kg Span-80,...

Embodiment 2

[0035] The environment-friendly easy degreasing bearing antirust oil of this embodiment is composed of the following components by weight: 875kg of LAN-10 total loss system oil, 50kg of calcium dinonyl naphthalene sulfonate, 50kg of calcium petroleum sulfonate, 10kg of Span-80 , dodecenyl succinate half ester 10kg, methyl benzotriazole 5kg.

[0036] The preparation method of the environment-friendly easy degreasing bearing antirust oil of the present embodiment comprises the following steps:

[0037] 1) Add 875kg of LAN-10 total loss system oil into the blending kettle, heat it to 100°C, and then keep stirring, add 50kg of dinonylnaphthalene calcium sulfonate and 50kg of petroleum calcium sulfonate to it at the same time, at this temperature Stir for 1 hour to dissolve calcium dinonylnaphthalene sulfonate and calcium petroleum sulfonate completely to obtain a premixture;

[0038] 2) Cool down the pre-mixture in step 1) to 90°C, add 10kg of dodecenylsuccinate half ester, 10kg ...

Embodiment 3

[0040] The environment-friendly easy degreasing bearing antirust oil of this embodiment is composed of the following components by weight: LAN-32 total loss system oil 880kg, dinonylnaphthalene calcium sulfonate 40kg, petroleum calcium sulfonate 60kg, 5kg Span-80 10kg of pentaerythritol ester of lanolin fatty acid, 5kg of tolyltriazole.

[0041] The preparation method of the environment-friendly easy degreasing bearing antirust oil of the present embodiment comprises the following steps:

[0042] 1) Add 880kg of LAN-32 total loss system oil into the blending kettle, heat it to 100°C, and then keep stirring, while adding 40kg of dinonylnaphthalene calcium sulfonate and 60kg of petroleum calcium sulfonate, at this temperature Stir for 1 hour to dissolve calcium dinonylnaphthalene sulfonate and calcium petroleum sulfonate completely to obtain a premixture;

[0043] 2) Cool the pre-mixture in step 1) to 90°C, add 10kg of lanolin fatty acid pentaerythritol ester, 5kg of Span-80, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com