Machine oil separation and lubrication control system for two-stroke pulse pump

A technology that separates lubrication and control systems. It is applied in the direction of engine control, engine lubrication, and timing lubrication. It can solve problems such as lubricating oil waste, achieve reasonable distribution, reduce exhaust emissions, and reduce consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

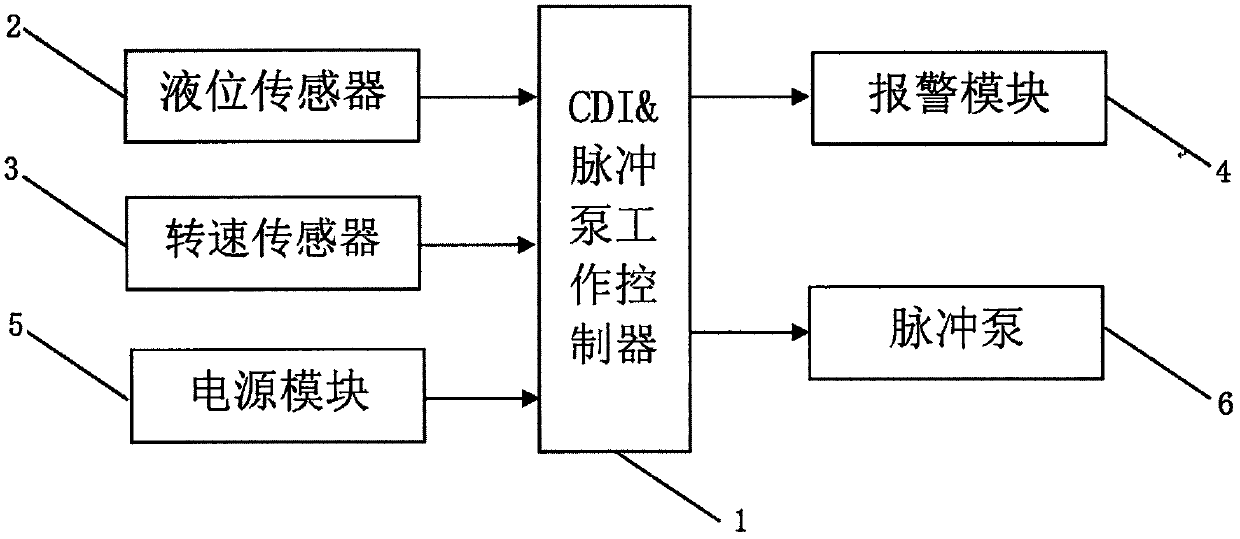

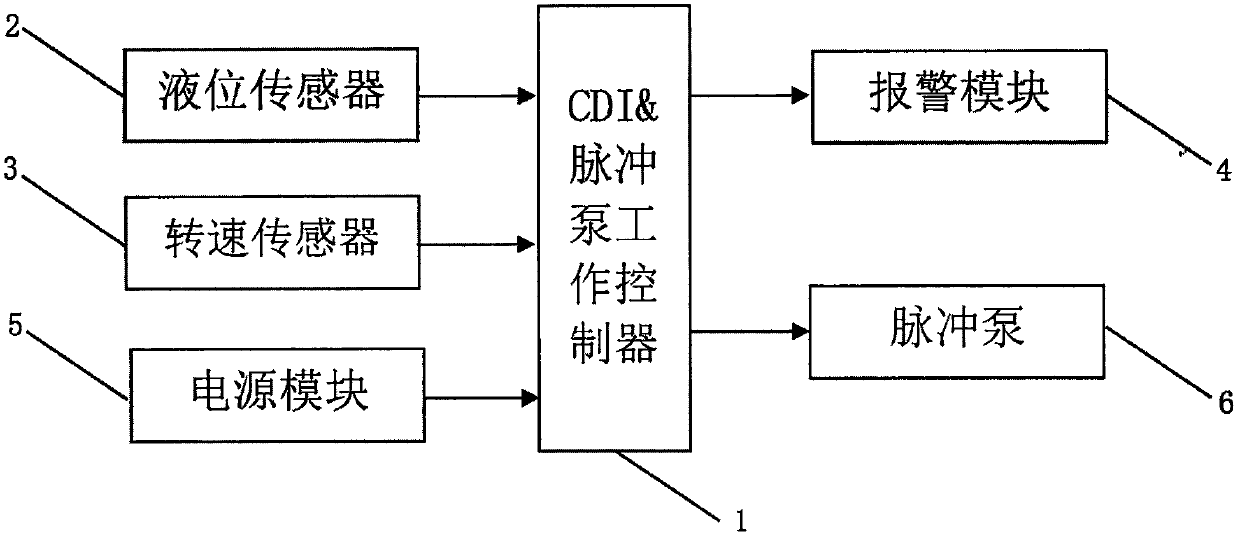

[0014] see figure 1 The present invention provides a technical solution: a two-stroke pulse pump oil separation and lubrication control system, including CDI & pulse pump work controller 1, liquid level sensor 2, speed sensor 3, alarm module 4, power supply module 5 and pulse pump 6; Wherein: the liquid level sensor 2 is connected with the CDI&pulse pump working controller 1, and the alarm module 4 is connected with the CDI&pulse pump working controller 1, wherein the liquid level sensor 2 is used to detect the liquid level of lubricating oil in the oil tank And feed back the oil level height information to the CDI&pulse pump controller 1, and at the same time, when the liquid level is lower than the set threshold, the CDI&pulse pump controller 1 drives the alarm module 4 to p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap