Device for testing multi-phase flow and heat transfer characteristics of supercritical water circulating fluidized bed

A technology of multiphase flow and heat transfer characteristics, applied in the field of multiphase flow, can solve the problems of reduced reactor efficiency and difficult expansion of reactors, etc., and achieve the effects of improving energy recovery utilization, reducing energy consumption, and improving measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

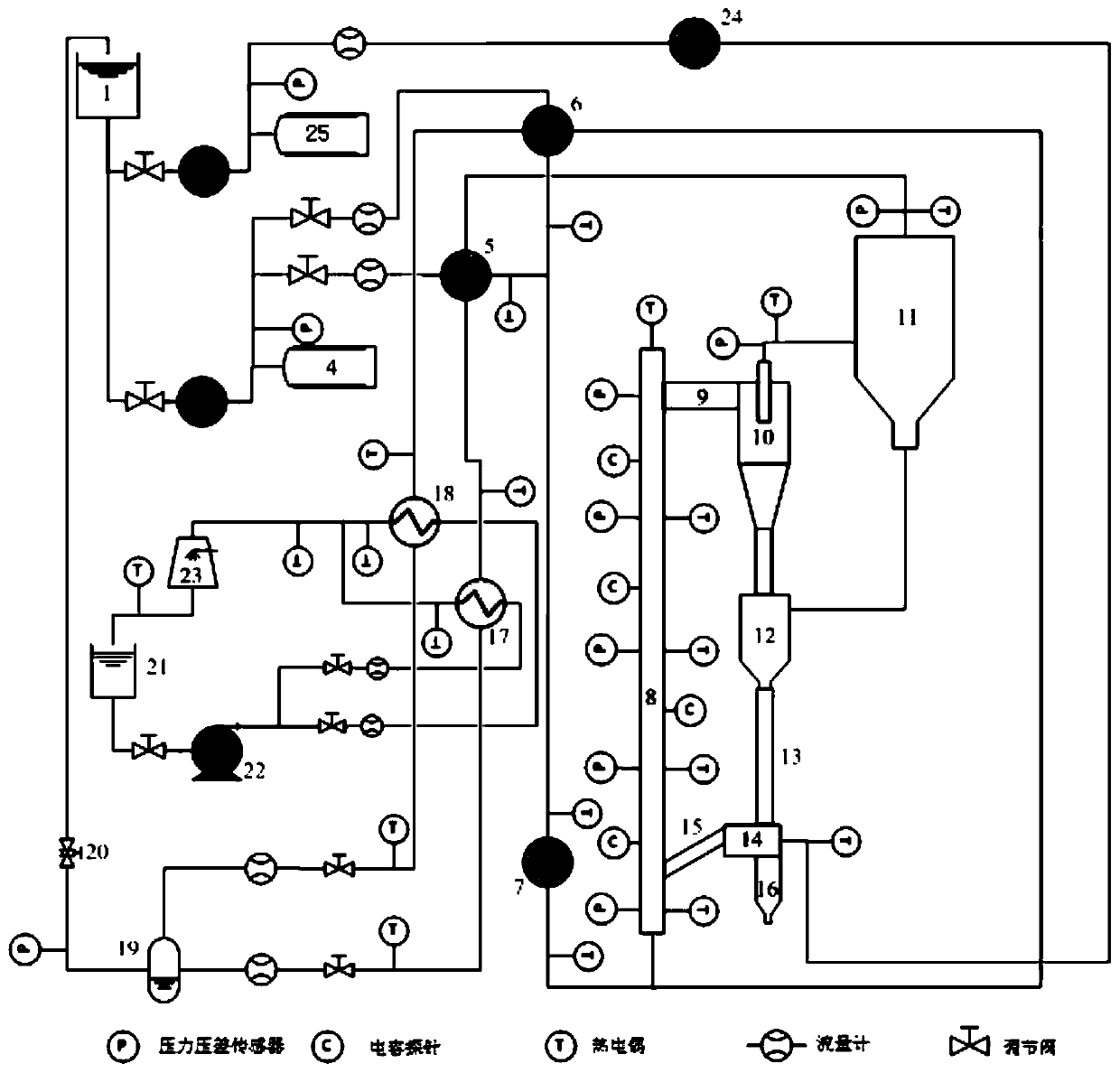

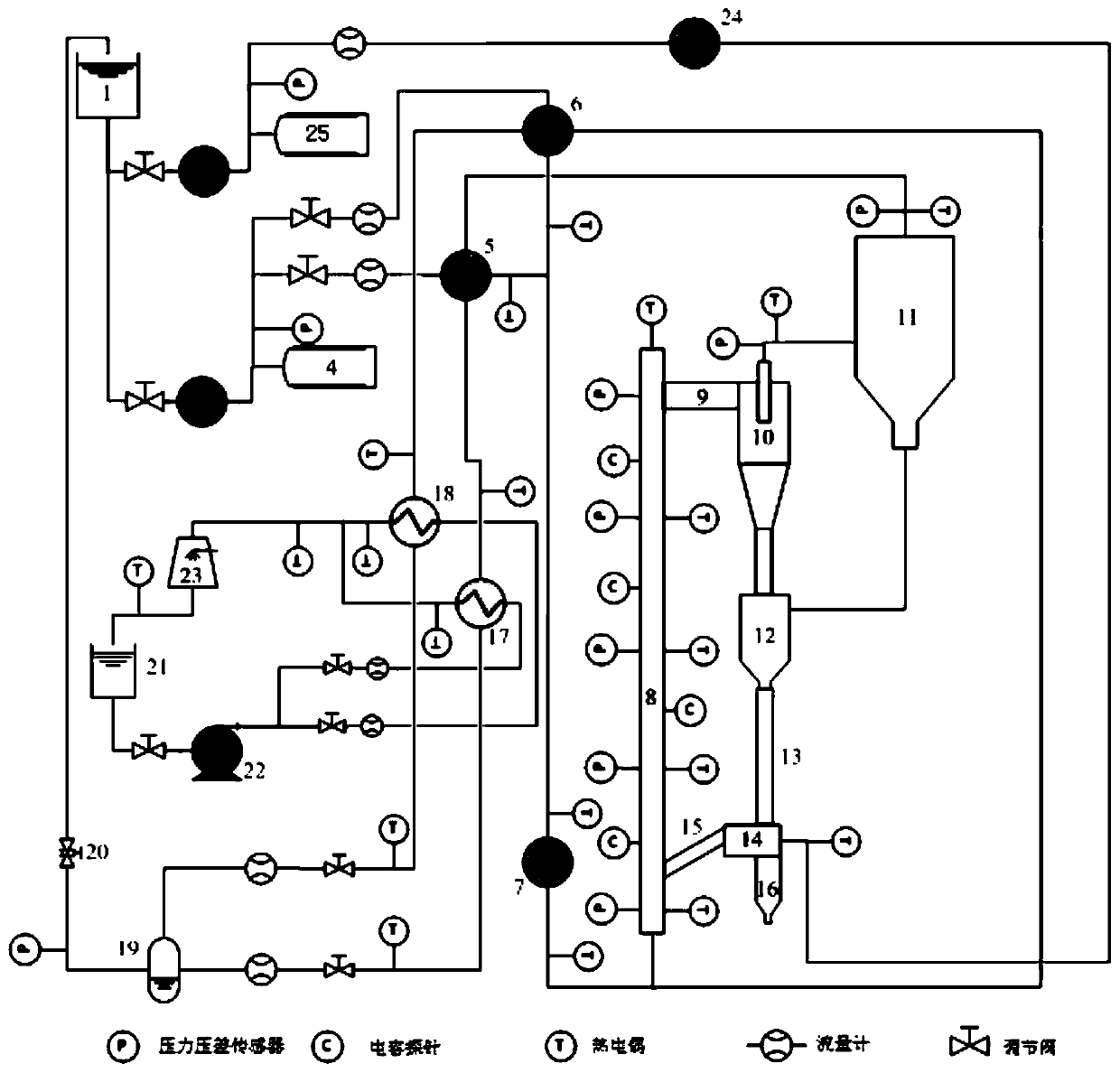

[0035] In order to solve the problems existing in the above-mentioned supercritical water fluidized bed reactor, the research team of the present invention adopts a new supercritical water circulating fluidized bed (rapid fluidization) gasification process to improve the efficiency and processing capacity of a single reactor. The supercritical water circulating fluidized bed gasification system combines the "pot" and "furnace" into one, its operating temperature and pressure are above the critical point of water, coal, biomass or catalyst particles and supercritical water are in the reactor The two-phase flow is in a fast fluidized state, and the gasification reaction between coal or biomass and supercritical water occurs directly.

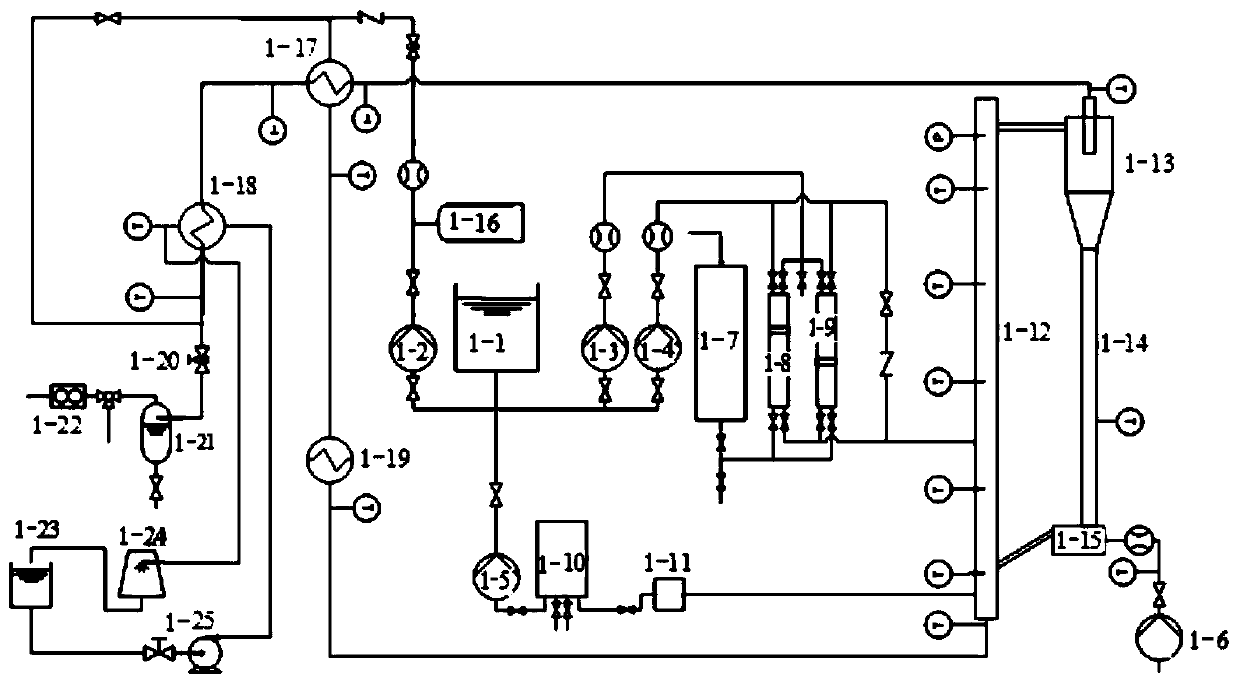

[0036] Such as figure 1 As shown, the supercritical water c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com