Optimal model predictive control method for double-inverter open winding induction motor

A technology of induction motor and double inverter, which is applied in motor-generator control, AC motor control, electronic commutation motor control, etc., can solve the difficulty in setting the value function weight factor, the complex setting of the internal current loop, and the output torque of the motor. The problem of large ripple, etc., can eliminate the problem of weight factor setting, reduce the calculation burden, and achieve the effect of simple algorithm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

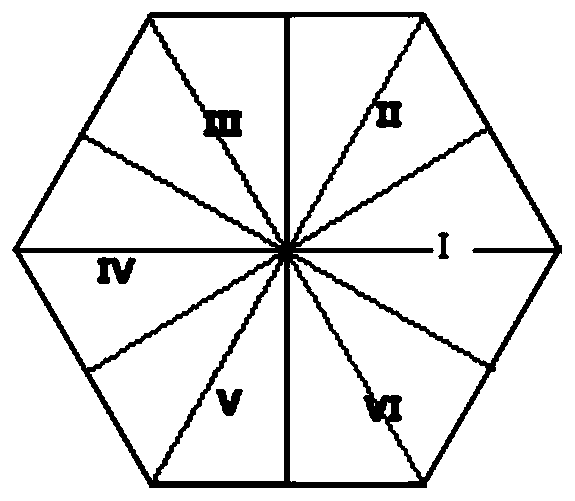

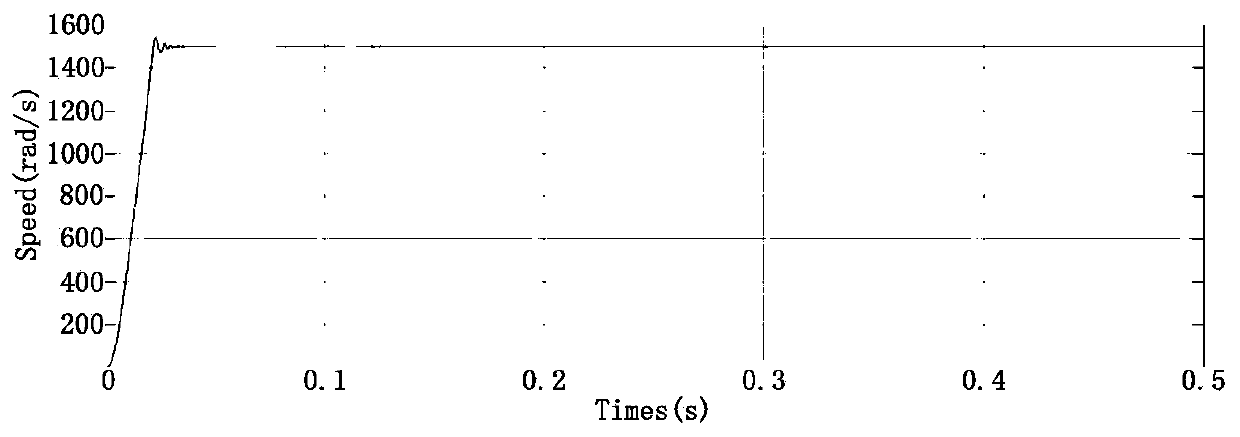

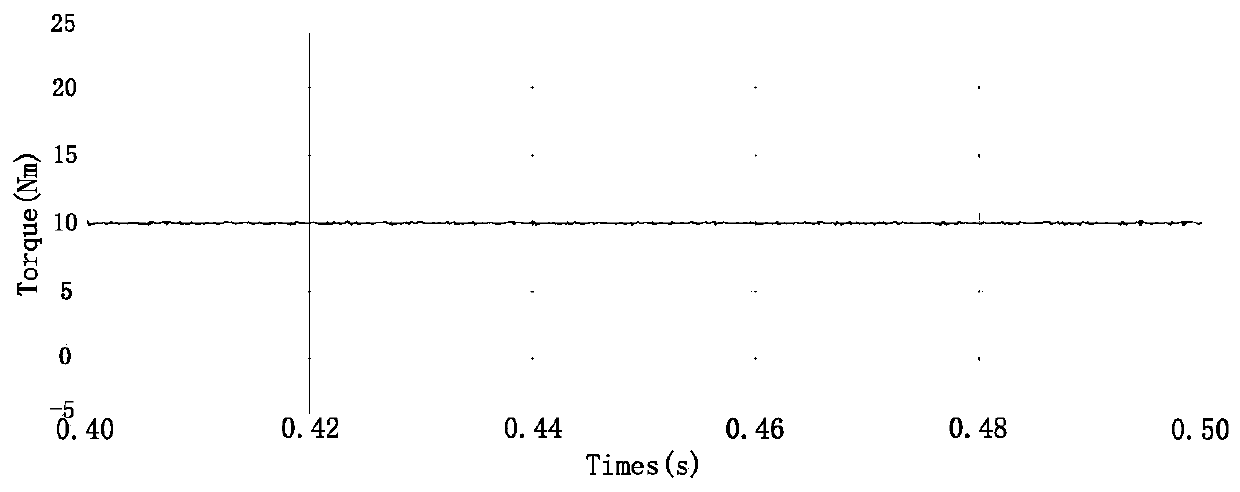

[0036] An optimized model predictive control method for a double-inverter open-winding induction motor, comprising the following steps:

[0037] By discretizing the OEWIM mathematical model, the predicted values of flux linkage and current can be obtained as follows:

[0038] ψ s (k+1)=ψ s (k)+T s [V s (k)|R s i s (k)] (1)

[0039]

[0040] According to the predicted values of flux linkage and current, the predicted electromagnetic torque is obtained, specifically:

[0041]

[0042] in

[0043]

[0044] In order to control the stator flux amplitude and electromagnetic torque at the same time, the value function can be constructed as follows, where λ is the weight factor of the flux amplitude:

[0045]

[0046] The value function consists of two parts, the first part is used to evaluate the torque error, and the second part is used to evaluate the flux linkage error, where λ represents the weight factor of the stator flux linkage respectively.

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com