Method for producing mineral slag micropowder by using titanium extraction tailings

A technology for extracting titanium tailings and slag micropowder is applied in the field of solid waste treatment and resource utilization, which can solve the problems of inability to meet the requirements of energy conservation and environmental protection, high cost of wastewater treatment, and limitation of treatment capacity, and achieves the maintenance of hydration activity and treatment cost. Low, high throughput effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

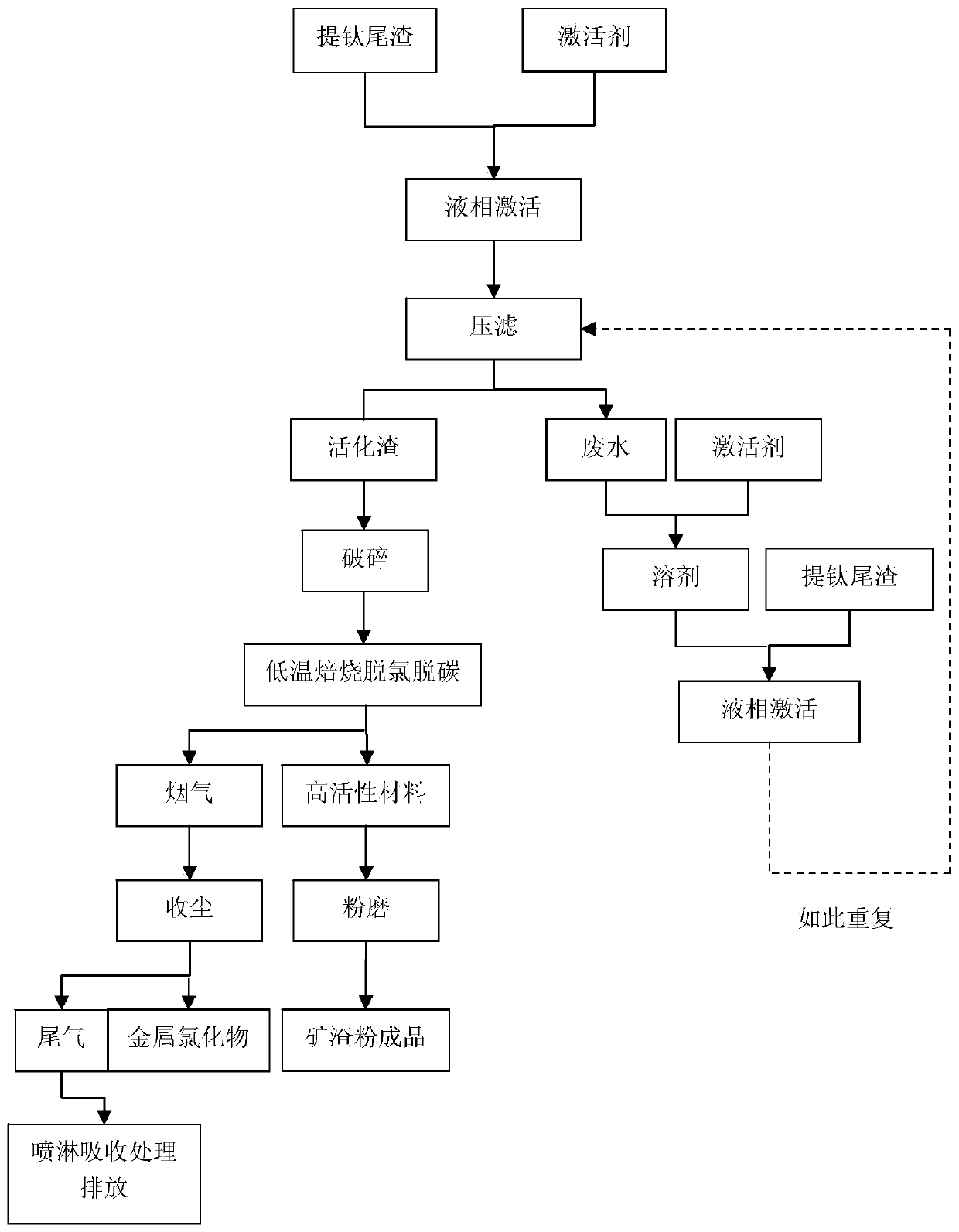

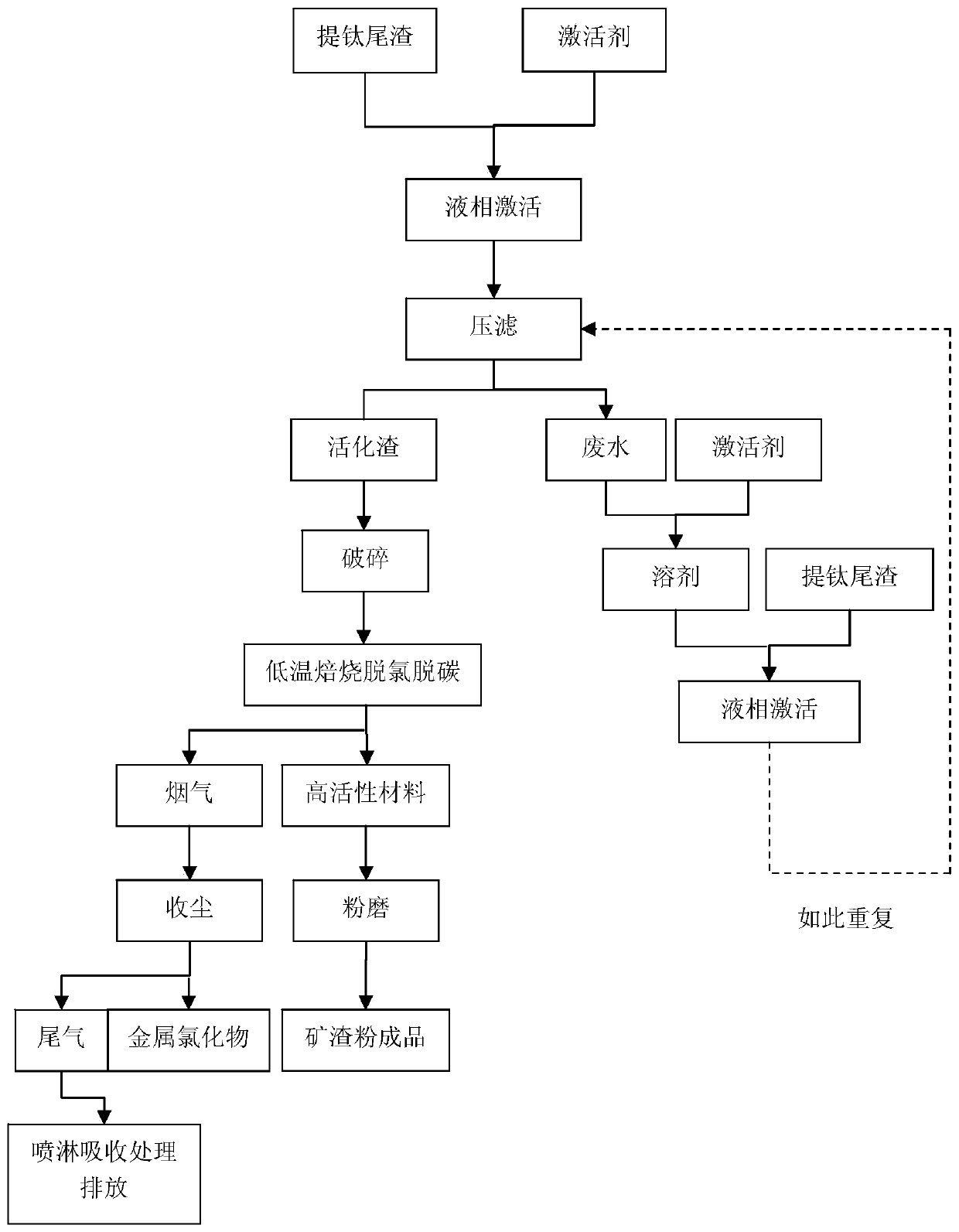

Image

Examples

Embodiment 1

[0047] The technical scheme of the invention is used to remove chlorine and carbon in the tailings of titanium extraction, and the tailings after dechlorination and decarburization are prepared into slag micropowder through grinding.

[0048] The specific steps are:

[0049] Mix the above titanium extraction tailings with 15% activator solution at a liquid-solid ratio of 1.8:1, stir and react for 10 minutes, enter a vertical filter press for pressure filtration, and obtain a filter cake, which is broken into small pieces of particles 400m 2 / kg, its 28-day activity index is 97%, and it can be used or sold instead of S95 grade slag micropowder.

Embodiment 2

[0051] The technical scheme of the invention is used to remove chlorine and carbon in the tailings of titanium extraction, and the tailings after dechlorination and decarburization are prepared into slag micropowder through grinding.

[0052] The specific steps are:

[0053] Mix the above-mentioned titanium extraction tailings with 10% activator solution at a liquid-solid ratio of 1.8:1, stir and react for 10 minutes, and enter the plate and frame filter press for pressure filtration to obtain a filter cake, which is broken into small pieces with particles 400m 2 / kg, its 28-day activity index is greater than 95%, and can be used or sold instead of S95 grade slag powder. Recycling the waste reaction liquid for 50 times still does not affect the dechlorination and decarburization effect.

Embodiment 3

[0055] The technical scheme of the invention is used to remove chlorine and carbon in the tailings of titanium extraction, and the tailings after dechlorination and decarburization are prepared into slag micropowder through grinding.

[0056] The specific steps are:

[0057] Mix the above titanium extraction tailings with 15% activator solution at a liquid-solid ratio of 1.8:1, stir and react for 10 minutes, enter a vertical filter press for pressure filtration, and obtain a filter cake, which is broken into small pieces of particles 400m 2 / kg, its 28-day activity index is 96%, and it can be used or sold instead of S95 grade slag micropowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com