A method for increasing the content of sds and rs in starch

A starch content technology, which is applied in the field of increasing the SDS and RS content in starch, can solve the problems of poor anthocyanin stability, complex process, food safety hazards, etc., and achieve the effect of retaining biological activity, simple preparation process, and improving light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

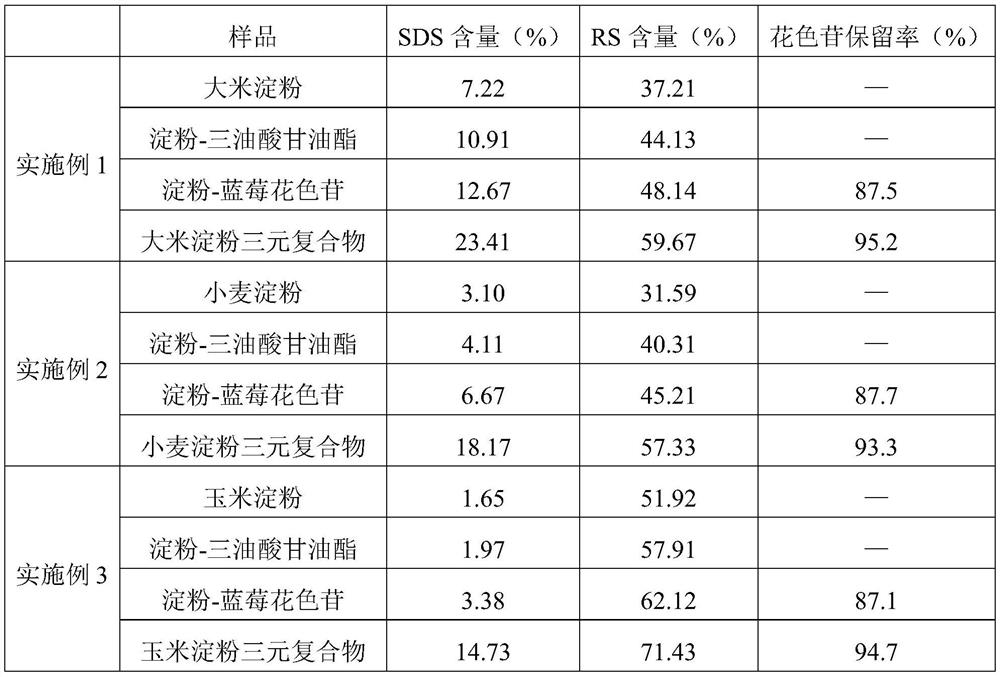

Embodiment 1

[0049] Firstly, dry-based rice starch is prepared into a starch solution with a mass concentration of 20%, and placed in a constant-temperature oscillating water bath. When the temperature rises to 95-100°C, start timing, oscillate at a constant temperature for 30 minutes, and homogenize for 1 minute at 10,000 rpm. , and kept at 90°C for 20 minutes. Prepare a triolein emulsion with a mass concentration of 2%, mix it with the rice starch solution after gelatinization treatment at a mass ratio of 1:1, homogenize at 10,000 rpm for 2 to 3 minutes, and heat at 90°C Shake at constant temperature for 30 minutes. The obtained rice starch-triolein composite solution was centrifuged at 5000r / min for 15min, the precipitate was retained, and washed with 50% ethanol / water solution to remove unreacted triolein, centrifuged under the same conditions, the The steps are repeated three times, and the obtained precipitate is the rice starch-triolein binary complex. Dissolve the binary complex ...

Embodiment 2

[0051] First, dry-based wheat starch is prepared into a starch solution with a mass concentration of 20%, and placed in a constant temperature oscillating water bath. When the temperature rises to 95-100°C, start timing, oscillate at a constant temperature for 30 minutes, and homogenize for 1 minute at 10,000 rpm. , and kept at 90°C for 20 minutes. Prepare a triolein emulsion with a mass concentration of 2%, mix it with the gelatinized wheat starch solution at a mass ratio of 1:1, homogenize for 2 to 3 minutes at 10,000 rpm, and mix it at 90°C Shake at constant temperature for 30 minutes. The obtained wheat starch-triolein composite solution was centrifuged at 5000r / min for 15min, the precipitate was retained, and washed with 50% ethanol / water solution to remove unreacted triolein, centrifuged under the same conditions, the The steps are repeated three times, and the obtained precipitate is the wheat starch-triolein binary compound. Dissolve the binary complex in a citric ac...

Embodiment 3

[0053] First, dry-based corn amylose was prepared into a starch solution with a mass concentration of 20%, and placed in a constant temperature shaking water bath. Mass for 1 min, and kept at 90°C for 20 min at a constant temperature. Prepare a triolein emulsion with a mass concentration of 2%, mix it with the gelatinized amylose at a mass ratio of 1:1, homogenize for 2 to 3 minutes at 10,000 rpm, and mix it at 90°C Shake at constant temperature for 30 minutes. The obtained amylose-triolein composite solution was centrifuged at 5000r / min for 15min, the precipitate was retained, and washed with 50% ethanol / water solution to remove unreacted triolein, centrifuged under the same conditions, This step is repeated three times, and the obtained precipitate is the amylose starch-triolein binary complex. Dissolve the binary complex in a citric acid buffer solution with a pH of 2.8 to 3.0 to obtain a suspension of a starch-triolein binary complex, wherein corn amylose on a dry basis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com