Silver-containing graphene slurry, preparation method thereof and product prepared from slurry

A graphene, silver ammonia solution technology, applied in the field of clothing processing, can solve the problems of no far-infrared heating, anti-ultraviolet function, heat insulation, inability to protect human health, poor antibacterial performance, etc., and achieves protection of human health and excellent antibacterial properties. , the effect of reducing bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

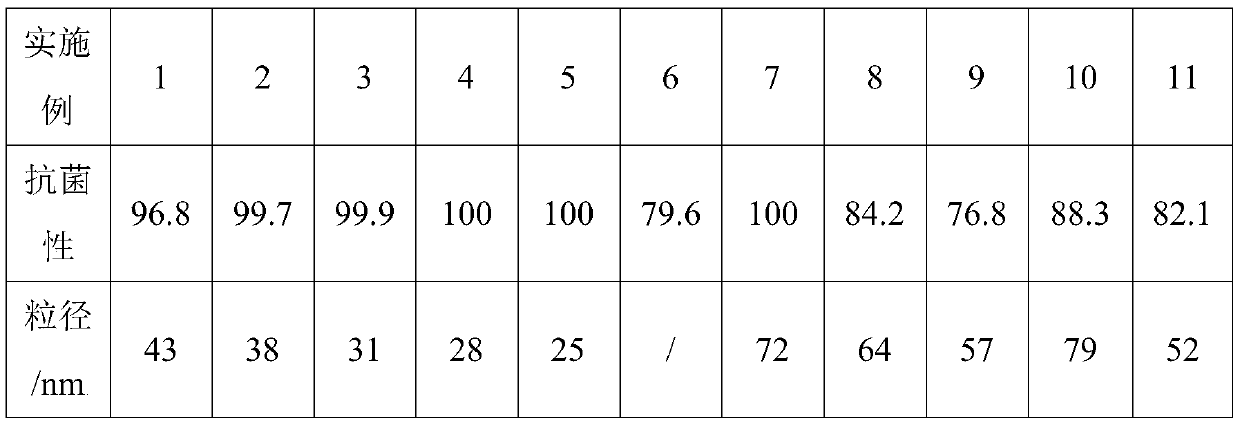

Examples

preparation example Construction

[0053] Second aspect of the present invention provides a kind of preparation method of silver-containing graphene slurry, comprises the steps:

[0054] S01: Take graphene, add emulsifier and polar solvent, add silver ammonia solution after ultrasonic vibration, stir evenly, add silver reducing agent, and obtain a mixture;

[0055] S02: adding the above mixture into the binder, the thickener, and the conductive agent to obtain the silver-containing graphene paste.

[0056] The third aspect of the present invention provides an application of the silver-containing graphene slurry prepared by the above preparation method on fabrics, non-woven fabrics, artificial leather, sponges, plastic films, flexible materials, clothing, and bedding.

Embodiment 1

[0060] Embodiment 1 provides a kind of silver-containing graphene slurry, by weight, comprising the following components: 0.2 parts of graphene, 0.1 part of emulsifier, 10 parts of polar solvent, 1 part of silver ammonia solution, 0.1 part of reducing agent , 5 parts of adhesive, 0.2 part of thickener, 1 part of conductive agent.

[0061] The graphene is graphene oxide; purchased from Changzhou Sixth Element Materials Technology Co., Ltd., model SE3122.

[0062] Described emulsifier is glyceryl stearate.

[0063] The polar solvent is a mixed solvent of water and ethanol, wherein the weight ratio of ethanol to water is 1:5.

[0064] The silver ammonia solution is prepared by the following method: add 100mL of 2% silver nitrate solution to a clean test tube, then drop in 2% dilute ammonia water drop by drop while shaking, until the initial precipitate just dissolves, and the silver ammonia solution is obtained .

[0065] The reducing agent is a mixture of glucose, sodium male...

Embodiment 2

[0073] Embodiment 2 provides a kind of silver-containing graphene slurry, by weight, comprising the following components: 10 parts of graphene, 15 parts of emulsifier, 80 parts of polar solvent, 10 parts of silver ammonia solution, 5 parts of reducing agent , 40 parts of adhesive, 8 parts of thickener, 10 parts of conductive agent.

[0074] The graphene is graphene oxide; purchased from Changzhou Sixth Element Materials Technology Co., Ltd., model SE3122.

[0075] Described emulsifier is glyceryl stearate.

[0076] The polar solvent is a mixed solvent of water and ethanol, wherein the weight ratio of ethanol to water is 1:5.

[0077] The silver ammonia solution is prepared by the following method: add 100mL of 2% silver nitrate solution to a clean test tube, then drop in 2% dilute ammonia water drop by drop while shaking, until the initial precipitate just dissolves, and the silver ammonia solution is obtained .

[0078] The reducing agent is a mixture of glucose, sodium ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com