Graphene-polyester fiber planting mat and manufacturing method thereof

A production method, the technology of vinyl polyester, which is applied in landscaping engineering and planting fields, can solve the problems of unseen popularization of agriculture, and achieve the effects of promoting plant cell growth, easy absorption, and loose soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

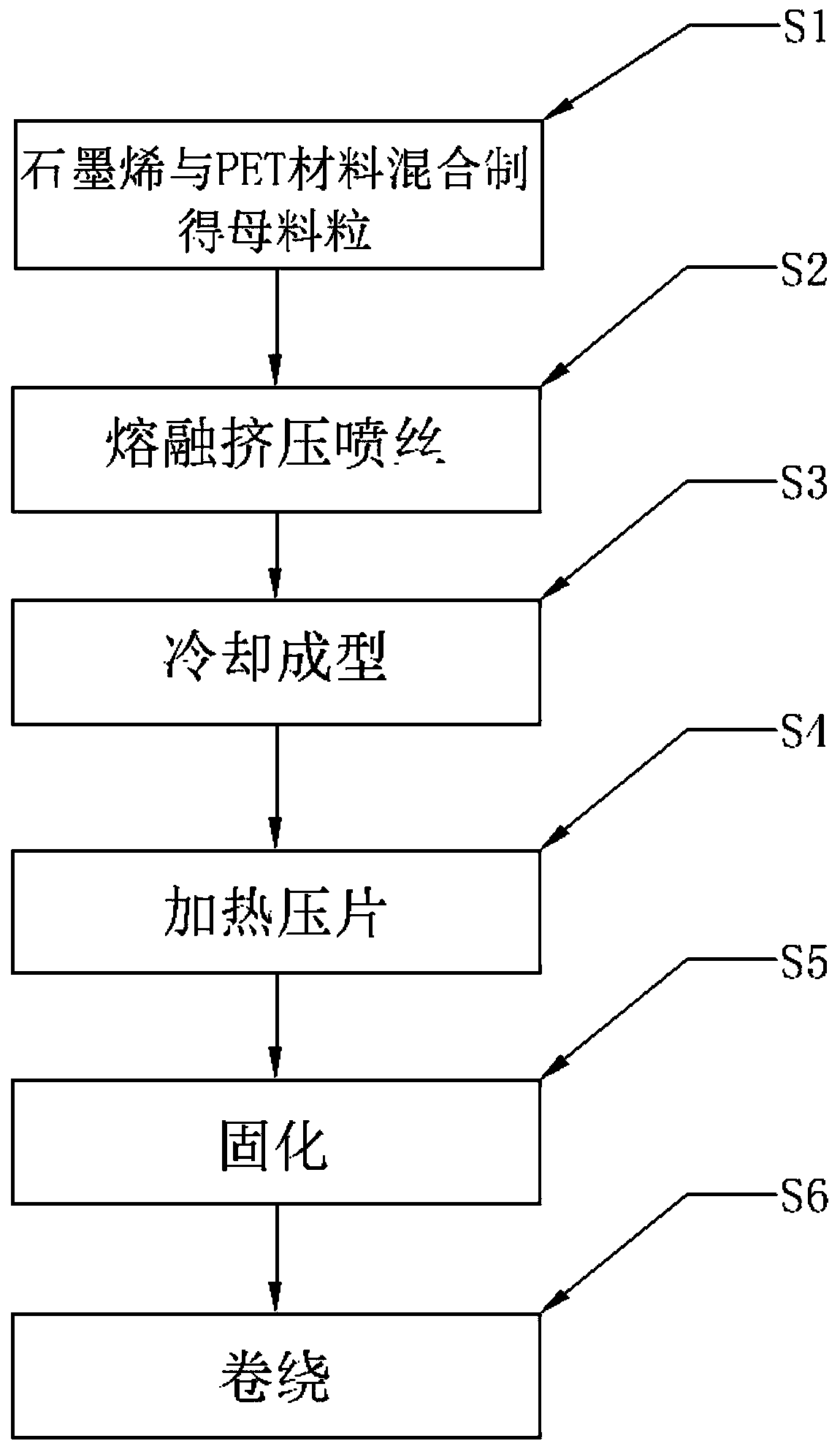

[0052] S1. Mixing graphene and PET materials to prepare masterbatch pellets: add 90-mesh graphene powder and 100-mesh PET material into the reactor for stirring, and then heat to make graphene and PET materials react to form masterbatch pellets. Among them, PET material The mixing ratio with graphene material is 3% for graphene material and 97% for PET material.

[0053] Wherein, the concrete steps that graphene is mixed with PET material to make masterbatch pellet are:

[0054] S11. Mixing of PET raw material and graphene: mixing 100-mesh PET material and graphene material, stirring continuously;

[0055] S12. Heating reaction: After the graphene material and PET material are fully mixed, the mixed material is sent to a circulating boiler for heat treatment, and a buffer is added to improve the dispersion and penetration effect. The buffer added is a mixture of graphene and PET materials The material ratio is 1:15000;

[0056] S13, heating and dispersing: further increase t...

specific Embodiment 2

[0076] S1. Graphene and PET materials are mixed to prepare masterbatch pellets: add 100-mesh graphene powder and 90-mesh PET material into the reactor for stirring, mix well and heat to make graphene and PET materials react to form masterbatch pellets, PET materials and graphite The mixing ratio of graphene material is 5% for graphene material and 95% for PET material;

[0077] Wherein, the concrete steps that graphene is mixed with PET material to make masterbatch pellet are:

[0078] S11. Mixing of PET raw material and graphene: mixing 90-mesh PET material and graphene material, stirring continuously;

[0079] S12. Heating reaction: After the graphene material and PET material are fully mixed, the mixed material is sent to a circulating boiler for heat treatment, and a buffer is added to improve the dispersion and penetration effect. The buffer added is a mixture of graphene and PET materials The material ratio is 1:1000;

[0080] S13, heating and dispersing: further incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fever temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap