Method for adjusting coercivity of rare earth-transition alloy film containing Gd ions

A technology of alloy thin film and coercive force, which is applied in the field of magnetic spintronics and recording technology materials, can solve the problems of unsatisfactory use effect, and achieve the effect of simple structure, simple preparation method and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for regulating the coercive force of a rare earth-transition alloy thin film containing Gd ions, the specific steps are as follows:

[0027] Step 1, the high-purity Gd chip and the iron target are combined to form a composite target, and then the composite target is placed in the target position of the vacuum sputtering chamber, the substrate is fixed on the substrate stage of the vacuum sputtering chamber, and then placed in the vacuum sputtering chamber Introduce high-purity argon gas, and the vacuum degree of the vacuum sputtering chamber is 5.2×10 -6 Pa;

[0028] Step 2, sputtering the buffer bottom layer on the substrate, the buffer bottom layer adopts a tantalum layer, and the thickness of the buffer bottom layer is 10nm;

[0029] Step 3, sputtering and growing a vertical rare earth-transition alloy film containing Gd on the buffer bottom layer, where the rare earth-transition alloy film containing Gd is a Gd-(Fe, Co) material;

[0030] Step 4, sputteri...

Embodiment 2

[0032] A method for regulating the coercive force of a rare earth-transition alloy thin film containing Gd ions, the specific steps are as follows:

[0033] Step 1, the high-purity Gd patch and the iron-cobalt alloy target are combined to form a composite target, and then the composite target is placed in the target position of the vacuum sputtering chamber, and the substrate is fixed on the substrate stage of the vacuum sputtering chamber, and the substrate is fixed Cleaning and drying are carried out before the substrate table, and the working gas is introduced into the vacuum sputtering chamber, and the vacuum degree of the vacuum sputtering chamber is 3.6×10 -6 Below Pa, ensure the working environment;

[0034] Step 2, sputtering the buffer bottom layer on the substrate;

[0035] Step 3, sputtering and growing a vertical rare earth-transition alloy thin film containing Gd on the buffer bottom layer, the rare earth-transition alloy thin film GdFeCo material containing Gd, ...

Embodiment 3

[0038] A method for regulating the coercive force of a rare earth-transition alloy thin film containing Gd ions, the specific steps are as follows:

[0039] Step 1, the high-purity Gd patch and the mosaic target are combined to form a composite target, and then the composite target is placed in the target position of the vacuum sputtering chamber, and the substrate is fixed on the substrate stage of the vacuum sputtering chamber, and the substrate is fixed on the base Clean and dry before the film stage, and pass the working gas into the vacuum sputtering chamber;

[0040] Step 2, sputtering the buffer bottom layer on the substrate;

[0041] Step 3, sputtering and growing a vertical rare earth-transition alloy film containing Gd on the buffer bottom layer;

[0042] Step 4, sputtering a protective top layer on the Gd-containing rare earth-transition alloy thin film to obtain the finished product.

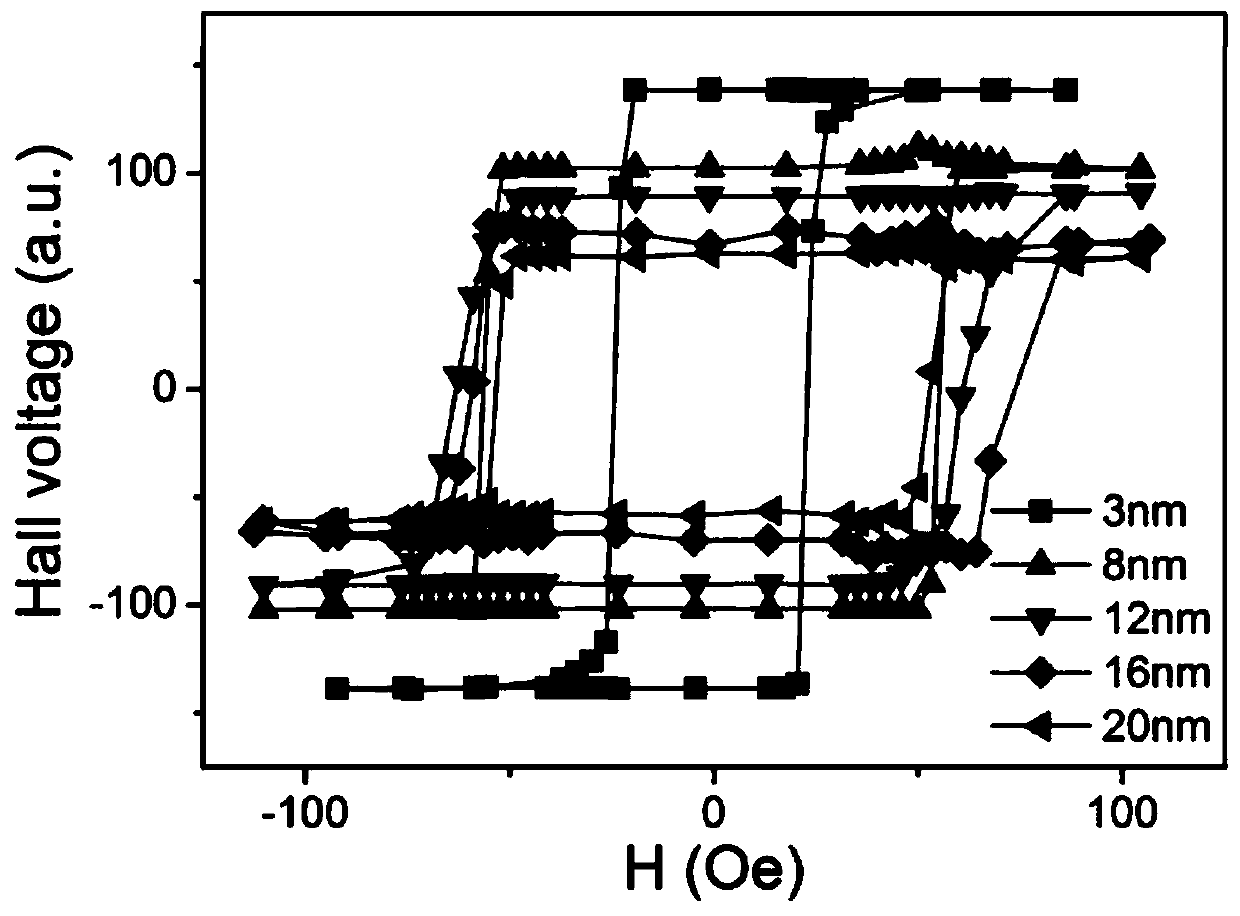

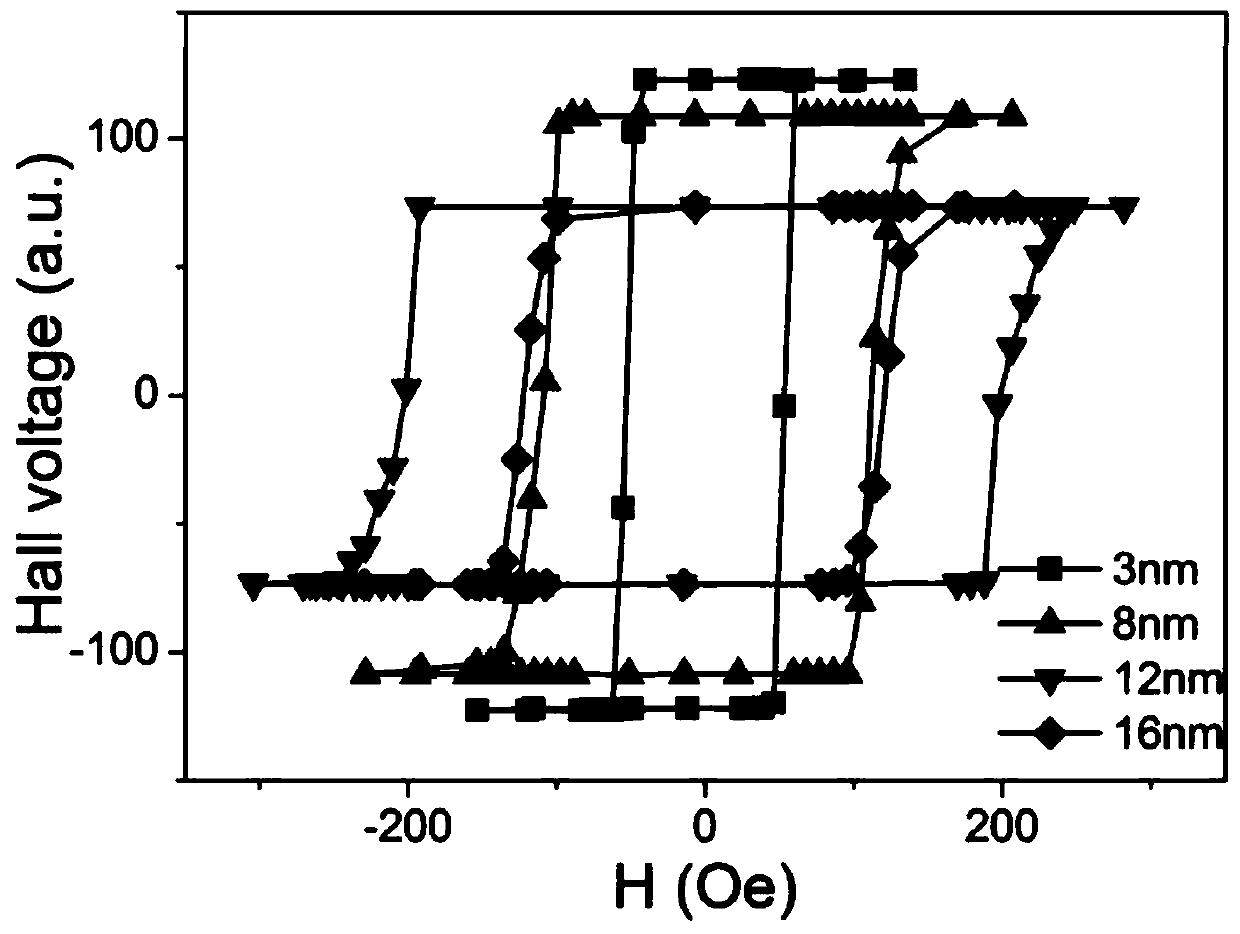

[0043] The finished product prepared in embodiment 3 is Si / Ta(5nm) / GdFeCo(20nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com