Dye composition and its preparation method as well as conductive heating fiber and its preparation method and conductive heating fabric

A dye composition and heating fiber technology, applied in dyeing method, textile and papermaking, etc., to achieve good color fastness, excellent electrical conductivity and heating effect, and excellent breaking strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

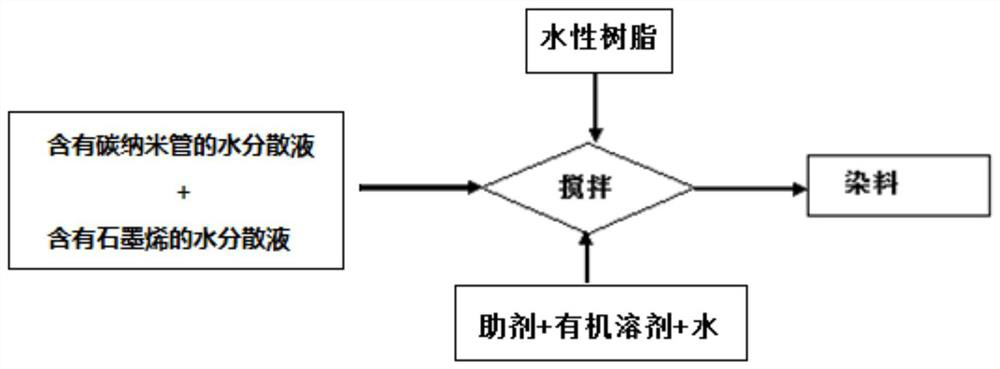

[0058] Such as figure 1 Shown, specifically, the preparation method of described dye composition comprises the following steps:

[0059] (1) Grinding and mixing carbon nanotubes with water to obtain an aqueous dispersion containing carbon nanotubes;

[0060] (2) Graphene is ground and mixed with water to obtain an aqueous dispersion containing graphene;

[0061] (3) mixing the aqueous dispersion of step (1) and step (2);

[0062] (4) Mixing the mixed aqueous dispersion obtained in step (3) with an aqueous resin, optionally an auxiliary agent, optionally an organic solvent, and water.

[0063] Wherein, in the present invention, preferably, the method is carried out under stirring conditions, and the stirring conditions include: the stirring rate is 200-800 rpm.

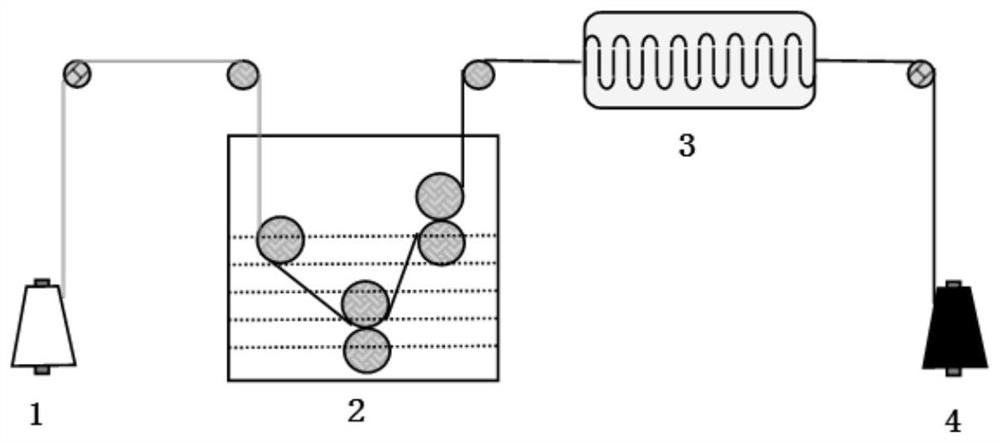

[0064] In the third aspect, the present invention provides a conductive heating fiber, wherein the conductive heating fiber is contact dyed by raw material fiber and the above-mentioned dye composition or the dye pr...

Embodiment 1

[0098] This example is used to illustrate the dye composition of the present invention and its preparation method.

[0099] Grinding and mixing multi-walled carbon nanotubes with water to obtain a dispersion with a multi-walled carbon nanotube content of 10% by weight; grinding and mixing graphene with water to obtain a dispersion with a graphene content of 5% by weight; 50g The aqueous dispersion containing multi-walled carbon nanotubes and 20g of the aqueous dispersion containing graphene were mixed with 16g of water and 1.0g of ethylene glycol butyl ether, and after stirring at a speed of 200rpm for 20min, 10g of water-based polyurethane emulsion 3218BTN was added, and 0.5 g defoamer F111, 1 g dispersant BYK-190 and 0.1 g thickener 8w, stirred at a speed of 400 rpm for 90 min and discharged; the dye composition A1 of the present invention was obtained.

Embodiment 2

[0101] This example is used to illustrate the dye composition of the present invention and its preparation method.

[0102] The preparation of the dye composition A2 is carried out according to the method described in Example 1, the difference is that the multi-walled carbon nanotube dispersion liquid with a multi-walled carbon nanotube content of 8% by weight; the graphite with a graphene content of 4% by weight ethylene dispersion; namely the dyestuff composition A2 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com