Method of directly and rapidly detecting uric acid

A uric acid and fast technology, applied in the direction of measuring devices, instruments, and material analysis through electromagnetic means, can solve the problems of ascorbic acid interference, poor anti-interference ability, high pH requirements, etc., achieve broad application prospects, improve work efficiency, and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Sensor preparation and characterization: A nanoporous gold sensor with a three-electrode system was assembled using an NPG / GCE electrode as a working electrode, a platinum electrode as a counter electrode, and a saturated calomel electrode as a reference electrode; 2 SO 4 Carry out cyclic voltammetry to scan 15 circles, and characterize the effective area of the NPG / GCE electrode by reducing the peak-to-peak current;

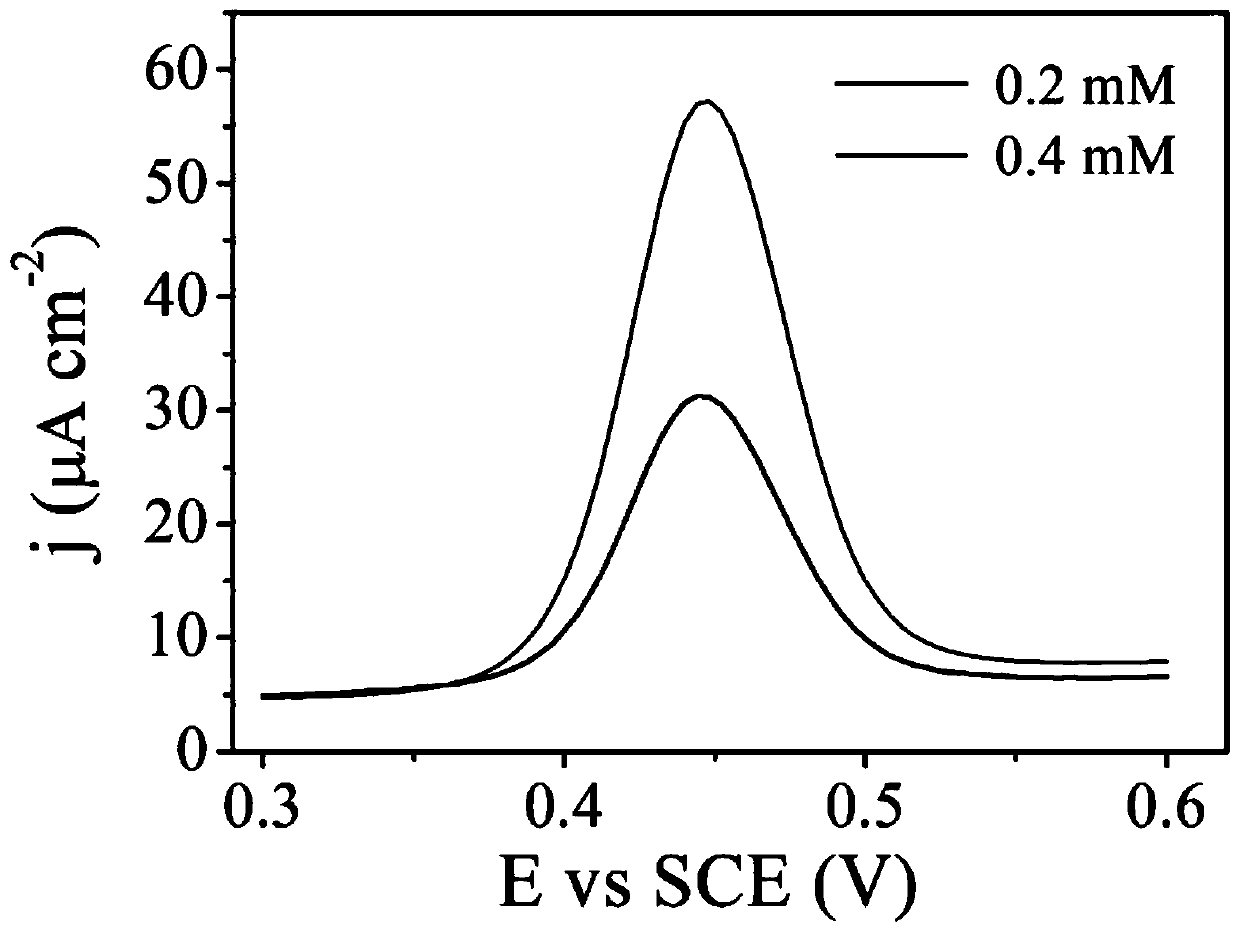

[0039] Detection of uric acid standard: 15mL pH 4.0 concentration of 100mM citric acid-sodium citrate buffer was purged with high-purity nitrogen for 5 minutes, and the prepared sensor was put into the reaction system of degassed citric acid-sodium citrate buffer In the process, add uric acid standards with final concentrations of 100 μM and 200 μM respectively, and use the sensor to detect the current response of added uric acid standards with known concentrations in the range of 0.3-0.6V; An obvious oxidation peak, the detection results are as follows ...

Embodiment 2

[0044] Sensor preparation and characterization: The prepared NPG / GCE electrode was used as the working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode to assemble a nanoporous gold sensor with a three-electrode system; 2 SO 4 Carry out cyclic voltammetry to scan 15 circles, and characterize the effective area of the NPG / GCE electrode by reducing the peak-to-peak current;

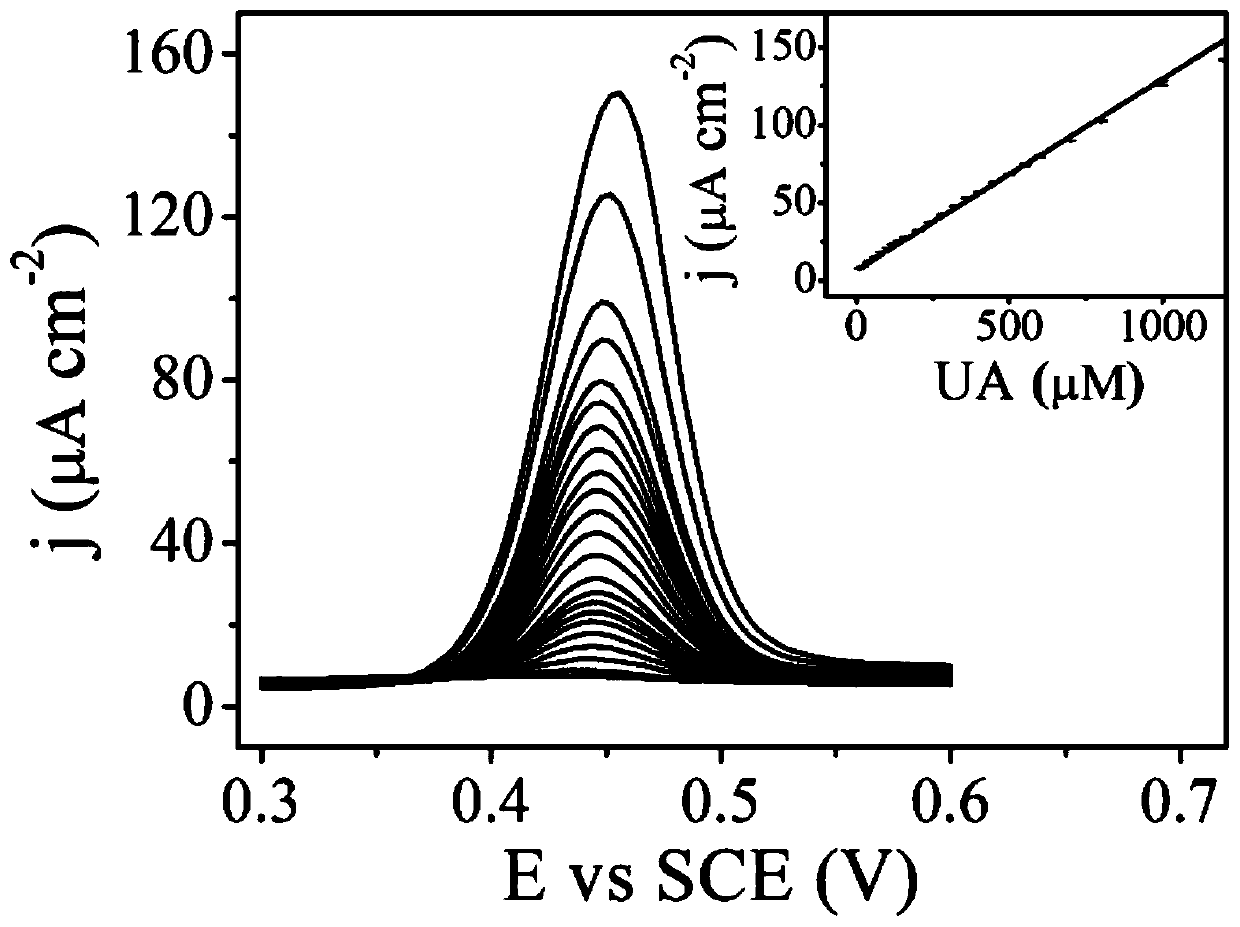

[0045] Sensor calibration or calibration: Blow 15mL pH 4.0 100mM citric acid-sodium citrate buffer solution with high-purity nitrogen for 5 minutes, put the prepared sensor into the reaction system of degassed citric acid-sodium citrate buffer solution, Add uric acid standard products with a final concentration of 10-1200 μM respectively, use the sensor to detect the current response of the added uric acid standard products with known corresponding concentrations in the interval of 0.3-0.6V, and make a concentratio...

Embodiment 3

[0050] Sensor preparation and characterization: The prepared NPG / GCE electrode was used as the working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode to assemble a nanoporous gold sensor with a three-electrode system; 2 SO 4 Carry out cyclic voltammetry to scan 15 circles, and characterize the effective area of the NPG / GCE electrode by reducing the peak-to-peak current;

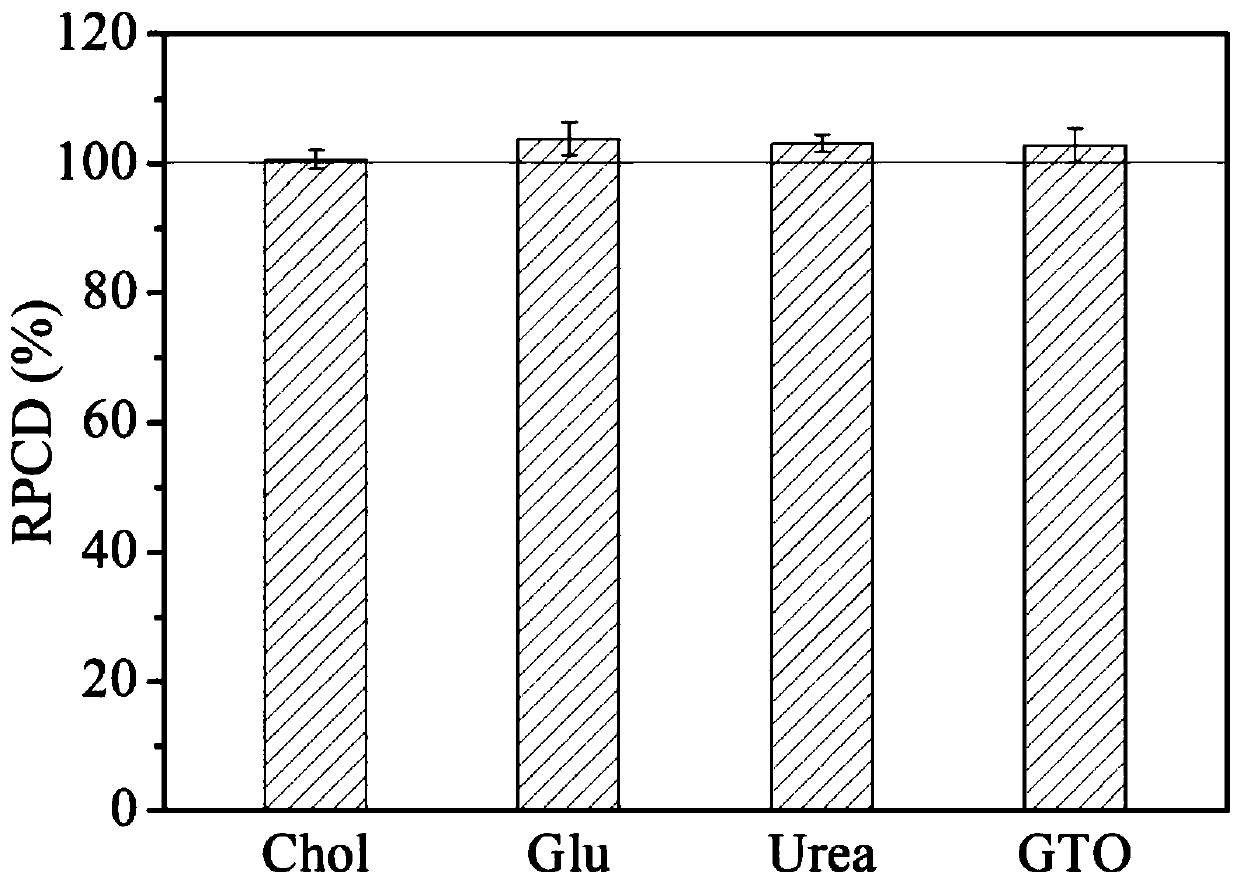

[0051] Sensor calibration or calibration: 15mL pH 4.0 concentration of 100mM citric acid-sodium citrate buffer is purged with high-purity nitrogen for 5 minutes, and the prepared sensor is placed in the reaction system of degassed citric acid-sodium citrate buffer , respectively adding uric acid standard products with a final concentration of 10-1200 μM, using the sensor to detect the current response of the added uric acid standard products with known corresponding concentrations in the interval of 0.3-0.6V, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com