Clostridium butyricum strain with high yield of 1,3-propanediol and sequential inoculation fermentation process

A technology of inoculation fermentation and Clostridium butyricum, applied in the field of bioengineering, can solve the problems of repeated batch fed-feed fermentation without Clostridium butyricum, long lag period of strain growth, poor fermentation ability, etc., to reduce fermentation steps and fermentation equipment investment, simplify fermentation steps, and solve the effect of long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1 Screening and domestication of Clostridium butyricum DL07 producing 1,3-propanediol

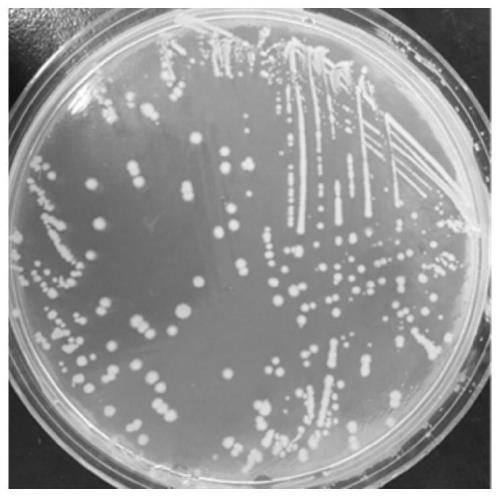

[0055] The anaerobic activated sludge comes from the anaerobic tank 1 of Dalian Dongtai Sewage Treatment Plant. In the anaerobic box, take 1 mL of anaerobic activated sludge, add it to an anaerobic bottle filled with 9 mL of sterile deaerated water, shake and mix evenly, and place it in a water bath at 80 °C for 10 min to kill non-spore bacteria. Use a sterile syringe to take 100 μL of the suspension and spread it on a solid seed medium plate, culture it anaerobically at 37°C, select a single colony that grows normally under anaerobic conditions, and perform subsequent streaking on the plate to purify the single bacteria. After 7 times of streaking on the plate, a single bacterium DL07 was finally isolated, and the colony morphology was as follows: figure 1 shown. After the single bacterium DL07 was enriched with the liquid seed medium, the bacterium was domesticated with t...

Embodiment 2

[0056] Embodiment 2 takes crude glycerol as the continuous feeding batch fed-batch fermentation of substrate

[0057] Put the Clostridium butyricum DL07 stored in the glycerol bottle at low temperature into the anaerobic bottle containing the seed medium at a 4% inoculum, and after culturing for 12 hours, transfer it to a new seed medium with a 2% inoculum, and cultivate 12h. After the two rounds of activation are completed, it is inserted into a fermenter with a 10% inoculum size for fermentation. Nitrogen gas was introduced at a rate of 0.1vvm 1h before inoculation, and adjusted to 0.05vvm 1h after inoculation until the end of fermentation. The fermentation medium uses crude glycerin, the initial glycerin concentration is 40g / L, and the yeast powder is 4g / L. During the fermentation process, the crude glycerol is continuously added to maintain the glycerol concentration at 10-25g / L. The fermentation time is 34h. The results are as follows: Figure 4 shown. The final 1,3-pr...

Embodiment 3

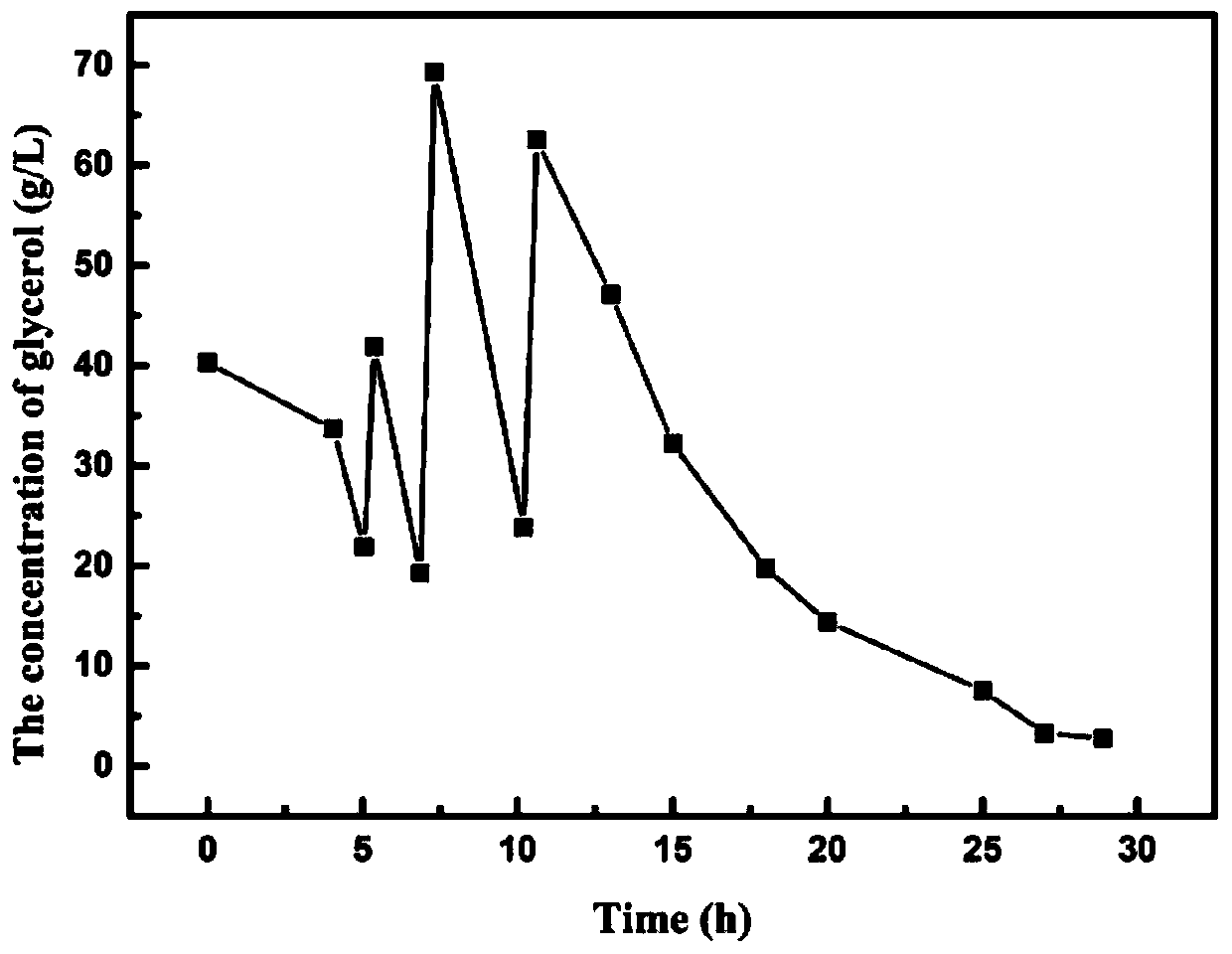

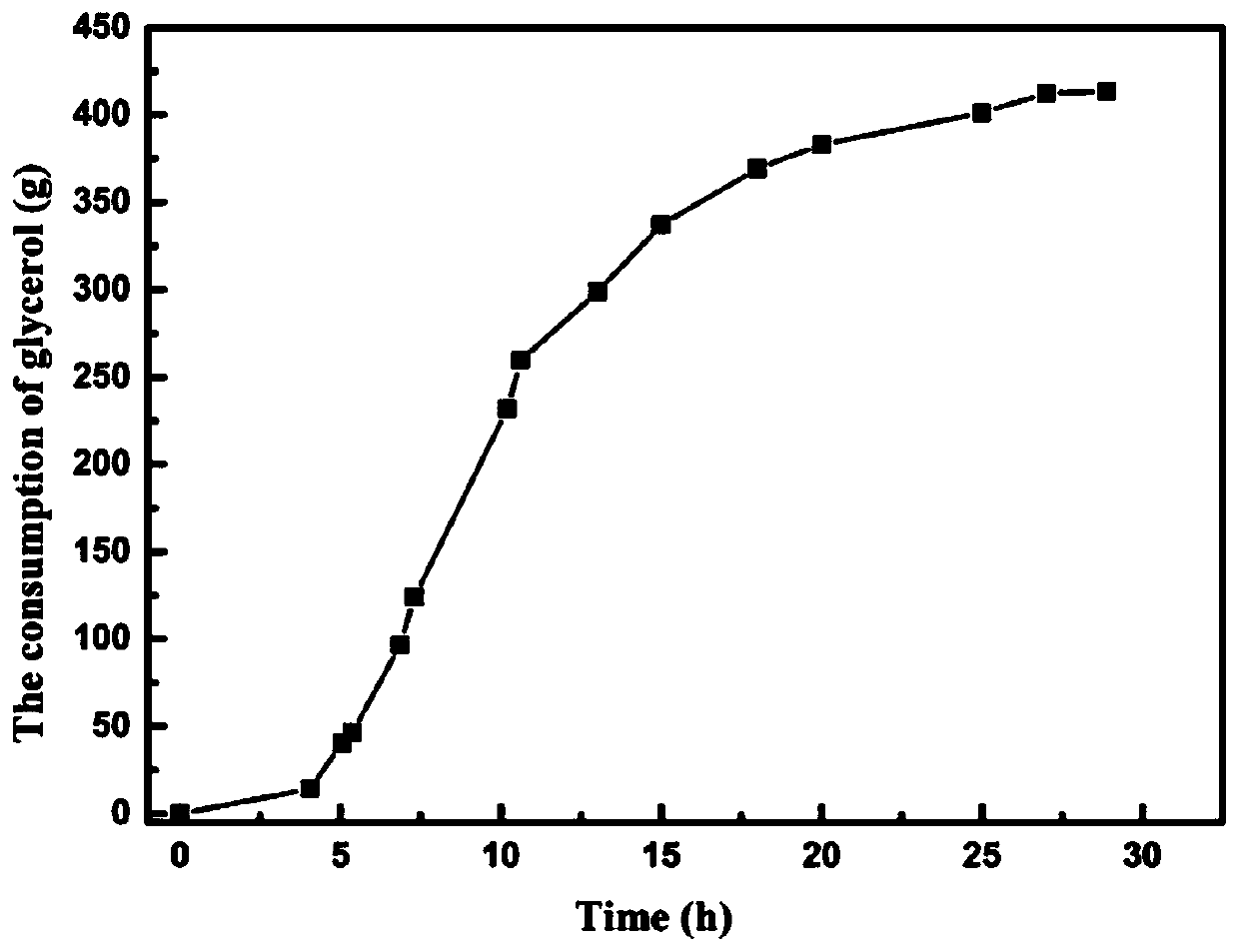

[0058] Embodiment 3 takes crude glycerol as the fed-batch fed-batch fermentation of substrate

[0059] The activated seed culture solution is inserted into a fermenter with 10% inoculum size to carry out fermentation. The fermentation medium has an initial crude glycerol concentration of 40 g / L and yeast powder of 2 g / L. In the batch-fed fermentation, it is divided into three stages of feeding, the first stage: when the glycerol concentration is lower than 20g / L, feed crude glycerol until the glycerin concentration is 40g / L; the second stage: when the glycerol concentration is lower than When the concentration of glycerol is 15g / L, feed crude glycerin until the concentration of glycerin is 65g / L; the third stage: when the concentration of glycerin is lower than 20g / L, feed crude glycerol to 60g / L; the fermentation time is 30h, and the results are as follows: Figure 5 shown. The final 1,3-propanediol concentration was 84.86g / L, the mass conversion rate was 0.521g / g, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com