Degradation method of oxalic acid in moringa oleifera leaves and application

A technology of Moringa oleifera leaves and oxalic acid, applied in the field of oxalic acid degradation in Moringa oleifera leaves, can solve problems such as increasing the risk of stone formation, reducing calcium absorption, and affecting the normal development of children

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

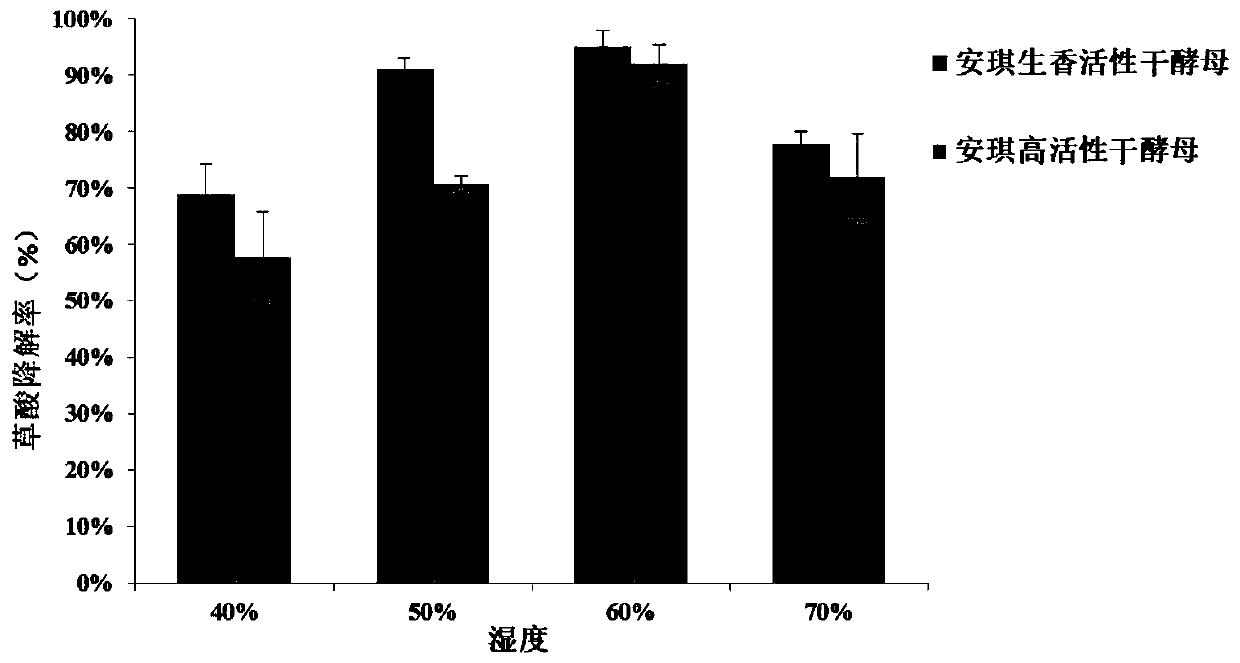

[0028] Embodiment one: solid-state fermentation experiment

[0029] 1. Strain preparation

[0030] 1.1 Strain activation

[0031] Accurately weigh 0.1g each of Angel High Active Dry Yeast (manufacturer: Angel Yeast Co., Ltd.) and Angel Aroma Active Dry Yeast (manufacturer: Angel Yeast Co., Ltd.), and inoculate the amount of dry yeast per liter. The weight is 0.1g, the yeast is inoculated into the sterile liquid wort medium, the temperature is 28°C, and the shaking culture is 150-250r / min for 24-48h. Both commercial dry yeasts were purchased from Angel Yeast Co., Ltd.

[0032] 1.2 Preparation of yeast seed solution

[0033] The activated yeast liquid is inoculated into the liquid wort medium according to the inoculum amount of 5-10%, and the temperature is 28°C, and the shaking culture is 150-250r / min for 72 hours to obtain the yeast seed liquid;

[0034] 2. Moringa fermentation

[0035] 2.1 Sterilization

[0036] Put a certain amount of moringa powder in a breathable gla...

Embodiment 2

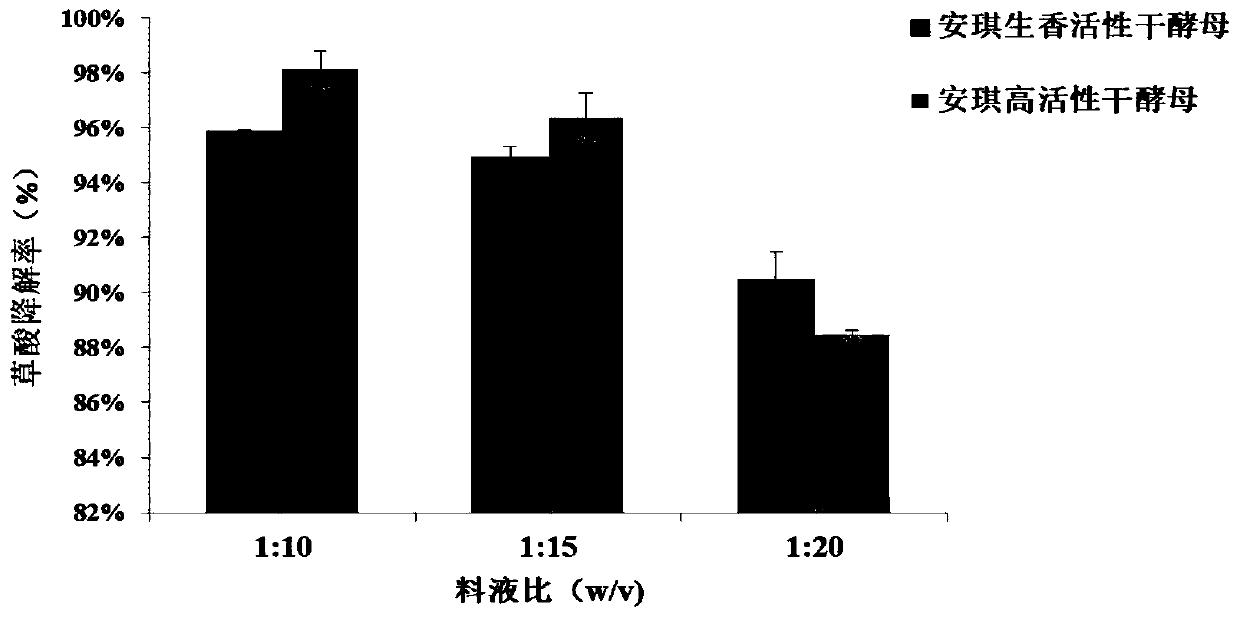

[0046] Embodiment two: liquid state fermentation experiment

[0047] The difference between embodiment two and the experimental procedure of embodiment one is only:

[0048]The step 2.2 method among the embodiment two is: the Moringa leaf powder that mixes sterilization with sterile water, make liquid material ratio (w / v) be respectively: Moringa leaf powder: sterile water=1:10,1 :15, 1:20, mix well, obtain Moringa powder solution;

[0049] The method of step 2.3 in Example 2 is: use a spectrophotometer to detect the OD value of the two yeast liquids obtained in step 1, and adjust the bacterial concentration of the two to be the same. The yeast seed liquid obtained in 1 was inoculated into the Moringa oleifera powder solution respectively. Stir evenly, seal and store in a constant temperature incubator at 28°C, shake and cultivate at 150-250r / min for 7 days.

[0050] The degradation rate of oxalic acid in the fermented liquid after yeast liquid fermentation is between 88.5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com