Microcapsule fire extinguishing material and preparation method thereof

A technology for fire extinguishing materials and microcapsules, which is applied in the field of microcapsule fire extinguishing materials and their preparation, can solve the problems that electrical equipment is not easy to use, the fire extinguishing medium cannot be rapidly vaporized, corroded, etc., and achieves easy acquisition, low production cost, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In order to achieve the above purpose, the present invention also proposes a preparation method of the microcapsule fire extinguishing material. The method is applied to the above-mentioned microcapsule fire extinguishing material, and the method comprises the following steps:

[0053] S1, adding clear water to the water phase substance, stirring until completely mixed to obtain the first mixed solution;

[0054] S2, adding the oil phase substance to dodecafluoro-2-methyl-3-pentanone or its homologue, and stirring until completely mixed to obtain a second mixed solution;

[0055] S3, adding the first mixed solution obtained in step S1 to the second mixed solution obtained in step S3, and stirring to obtain a microcapsule fire extinguishing material.

[0056] Wherein, in step S1, the stirring speed is 15000-25000r / min, such as 15000r / min, 20000r / min, or 25000r / min; the stirring time is 5-10min, such as 5min, or 7.5min, or 10min.

[0057] In step S2, the stirring speed ...

Embodiment approach

[0060] As an implementation manner, after the step S3, it also includes:

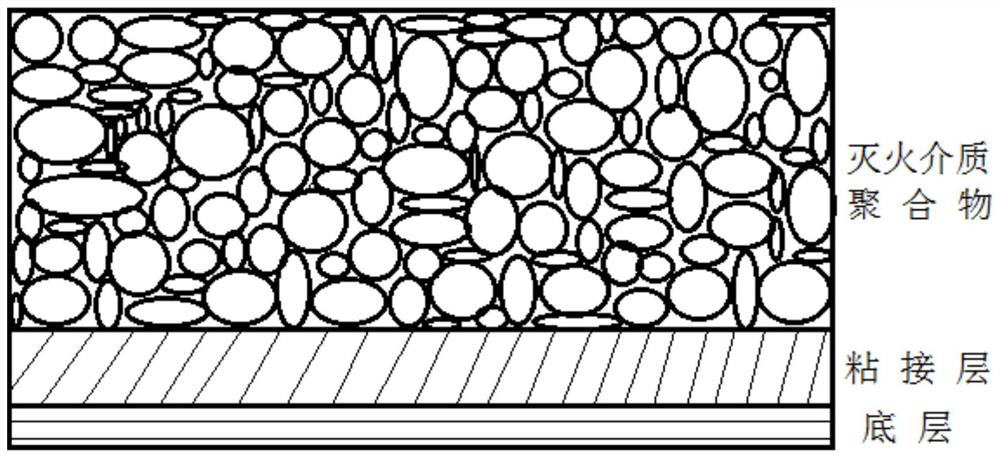

[0061] Step S4, attaching a double-sided adhesive foam substrate with a thickness of 1 to 2 mm on the capsule wall;

[0062] Step S6, sticking non-woven fabric or kraft paper on the double-sided adhesive tape.

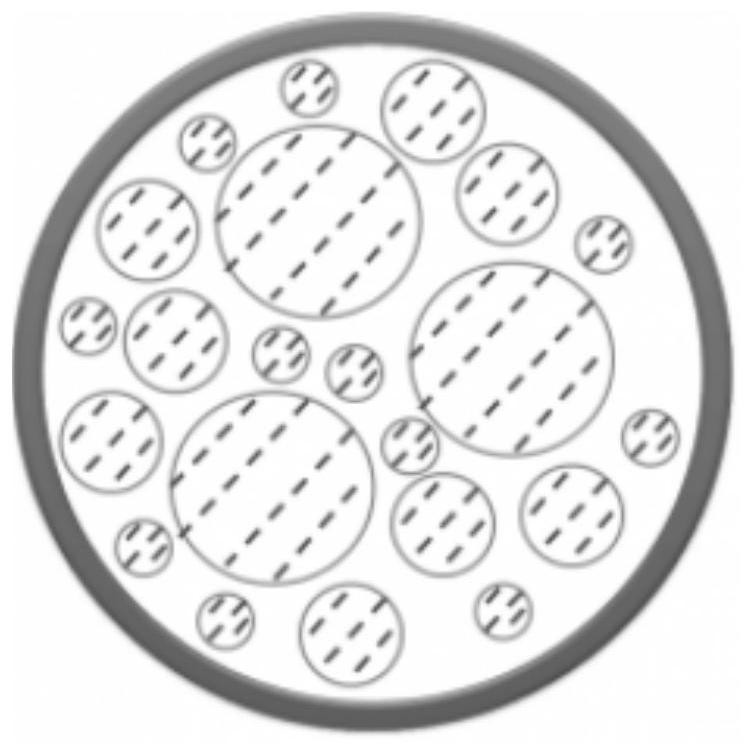

[0063] In the present invention, the microcapsule coating material is made of synthetic polymer material mixed material, which has certain strength and rigidity, plays the role of structural support and provides a loading space for the fire extinguishing medium. The present invention can be mainly used in the space where electric cabinets, switch boxes, etc. are installed in electric equipment, and can also be used in various closed or relatively closed environments, and has wide applicability.

[0064] The capsule core used in the present invention is difluoro-2-methyl-3-pentanone or its homologues with high-efficiency fire extinguishing properties, and the method for preparing microcapsules t...

Embodiment 1

[0067] In this example, based on the total mass of the components of the microcapsule fire extinguishing material as 100 g, dodecafluoro-2-methyl-3-pentanone: 80 g; ethylene glycol: 10 g; benzenetricarboxylic acid chloride: 10 g.

[0068] It should be noted that, in the process of preparing the microcapsule fire extinguishing material using the preparation method of the microcapsule fire extinguishing material of the present invention, 60 g of water needs to be added. The preparation method of the microcapsule fire extinguishing material proposed in this embodiment includes the following steps:

[0069] Weigh 80 g of dodecafluoro-2-methyl-3-pentanone, 10 g of ethylene glycol, 10 g of trimellitic acid chloride, and 60 g of clear water. Mix ethylene glycol and water evenly, trimelliticoyl chloride and dodecafluoro-2-methyl-3-pentanone evenly. Pour the aqueous solution of ethylene glycol into another mixture evenly. The temperature is controlled between 20°C and 40°C, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com