Nickel-based methanation catalyst, controllable solution combustion preparation method and applications thereof

A methanation catalyst and solution combustion technology, applied in the direction of catalyst activation/preparation, carbon compound catalyst, physical/chemical process catalyst, etc., can solve problems such as unfavorable industrialization promotion, partial agglomeration of materials, grain growth, etc., and save preparation time cycle, high catalytic activity, mild combustion reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Accurately weigh 9.91 g Ni(NO 3 ) 2 •6H 2 O, 58.87 g Al(NO 3 ) 3 •9H 2 0 and 5.79 g urea, prepare a mixed solution, place the mixed solution in a 60°C water bath and stir constantly, add 15.29 g ammonium nitrate in the process to obtain a precursor solution, wherein (Ni 2+ +Al 3+ ) / ammonium nitrate molar ratio is 1:1;

[0025] (2) Place the precursor solution in the atmosphere protective cover of the microwave heating device, the continuous flow rate is 15 mL / min, and the volume composition is 3.0%H 2 / 97.0%N 2 After a period of time, start the microwave heating device with a heating power of 500 W. After the solution is heated, it will spontaneously combust, collect the powder, grind it and granulate it to 160-200 mesh, and then obtain a nickel-based methanation catalyst. The composition is: Ni 20wt.%, Al 2 o 3 80wt.%.

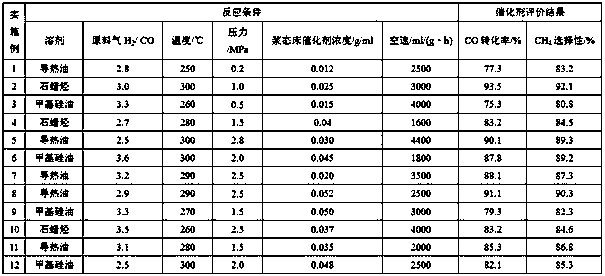

[0026] The specific conditions and results of catalyst activity evaluation in synthesis gas to methane reaction are shown in Attached ...

Embodiment 2

[0028] (1) Accurately weigh 9.91 g Ni(NO 3 ) 2 •6H 2 O, 58.87 g Al(NO 3 ) 3 •9H 2 0 and 5.79 g of urea, prepare a mixed solution, place the mixed solution under 60°C water bath and stir constantly, add 14.72 g of ammonium acetate in the process to obtain a precursor solution, wherein (Ni 2+ +Al 3+ ) / ammonium acetate molar ratio is 1:1;

[0029] (2) Place the precursor solution in the atmosphere protective cover of the microwave heating device, the continuous flow rate is 50 mL / min, and the volume composition is 5.0%H 2 / 95.0%Ar mixed gas, start the microwave heating device after a period of time, the heating power is 700W, after the liquid is heated, it will burn spontaneously, collect the powder, grind it and granulate it to 80~120 mesh, and then you can get the nickel-based methanation catalyst , the catalyst composition is: Ni 20wt.%, Al 2 o 3 80wt.%.

[0030] The specific conditions and results of catalyst activity evaluation in synthesis gas to methane reaction...

Embodiment 3

[0032] (1) Accurately weigh 9.91 g Ni(NO 3 ) 2 •6H2 O, 58.87 g Al(NO 3 ) 3 •9H 2 0 and 5.79 g urea, prepare a mixed solution, place the mixed solution under 60°C water bath and stir constantly, add 34.41 g glucose to obtain the precursor solution in the process, wherein (Ni 2+ +Al 3+ ) / glucose molar ratio is 1:1;

[0033] (2) Place the precursor solution in the atmosphere protective cover of the microwave heating device, the continuous flow rate is 25 mL / min, and the volume composition is 2.5%H 2 / 97.5%Ar mixed gas, start the microwave heating device after a period of time, the heating power is 800W, the precursor solution is heated and spontaneously combusted, the powder is collected, ground and granulated to 120~160 mesh, and the methanation nickel-based catalyst is obtained , the catalyst composition is: Ni 20wt.%, Al 2 o 3 80wt.%.

[0034] See attached table 1 for the specific conditions and results of catalyst activity evaluation in synthesis gas to methane reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com