Method for constructing enhanced denitrification artificial wetland, artificial wetland, and enhanced denitrification method

A constructed wetland and denitrification technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult control of effluent water quality, waste of sulfur resources, and denitrification efficiency Slow and other problems, to achieve the effect of stable effluent total nitrogen (TN, strong impact load resistance, convenient operation and management)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

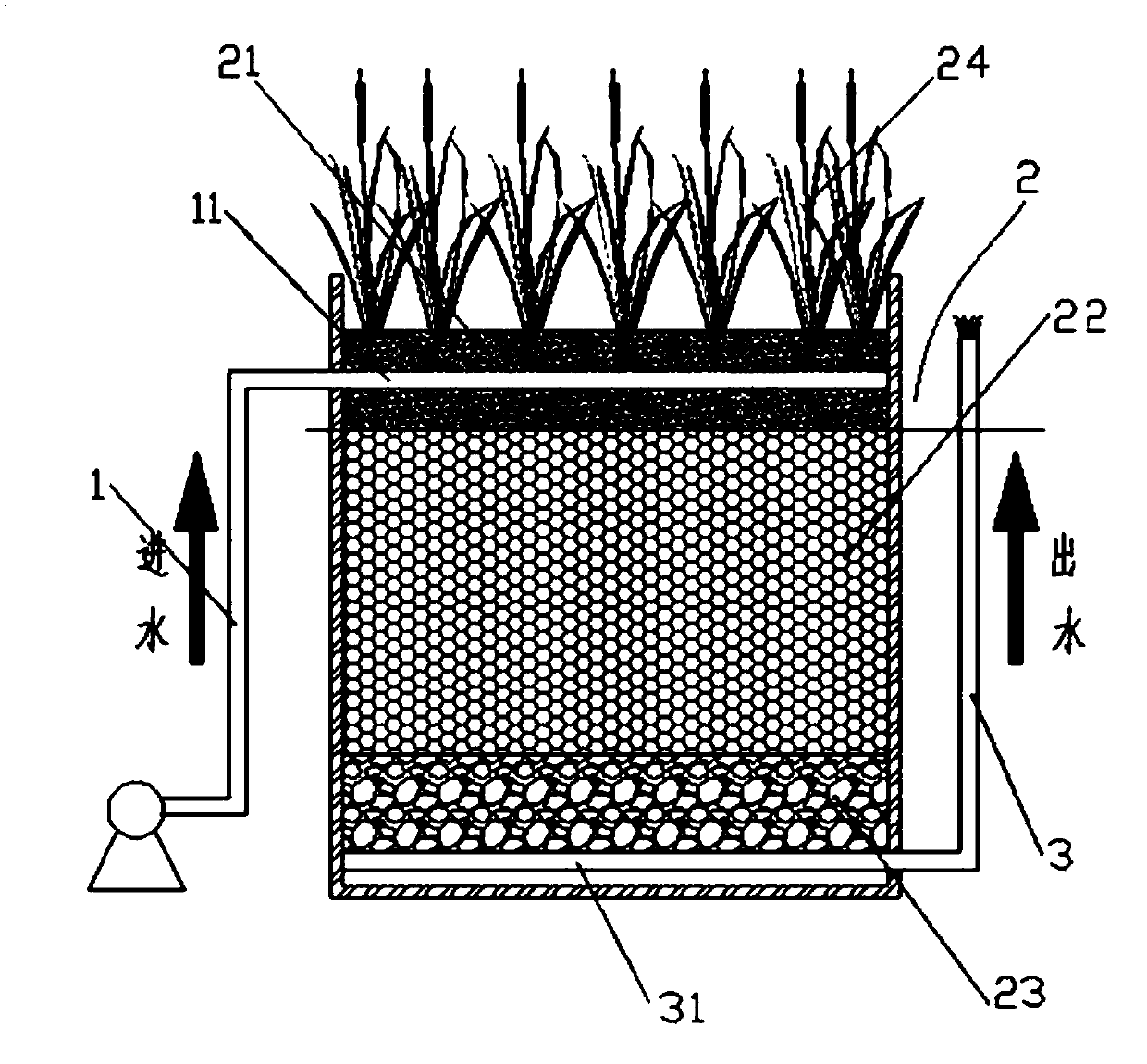

[0095] Example 1 Establishment of Downward Vertical Subsurface Flow Coupled Sulfur Autotrophic Denitrification Constructed Wetland

[0096] 1. Build subsurface artificial wetlands

[0097] 1-1) Excavation of constructed wetland bed

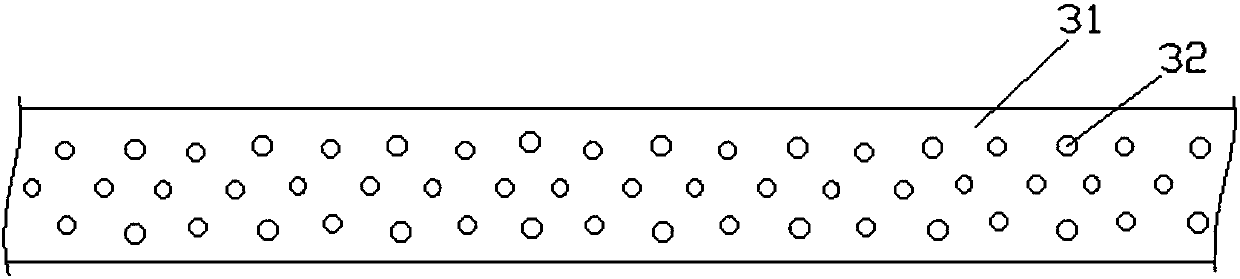

[0098] In the sewage area to be treated, excavate a subsurface flow artificial wetland bed with a depth of 2m (usually <3m), set a water inlet on the upper part of the artificial wetland bed, connect with the water inlet, and introduce sewage into the artificial wetland; open a water outlet at the bottom, and connect with the water inlet The outlet pipes are connected to lead the outlet water after enhanced denitrification treatment to the constructed wetland;

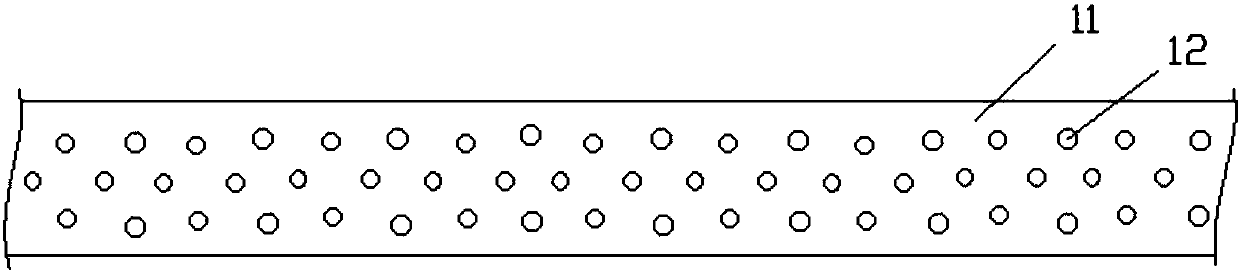

[0099] 1-2) Preparation of filler

[0100] 1-2A) Mix sulfur, limestone, zeolite and volcanic rock with a particle size of 30 to 35 mm evenly to prepare the filler in the sulfur packing area, that is, sulfur / limestone / zeolite / volcanic rock filler, wherein sulfur, limestone, zeolite, and v...

Embodiment 2

[0129] Taking the effluent from the filter cloth filter room of a sewage treatment plant in Changge City as an example to carry out enhanced denitrification treatment, the amount and quality of sewage water are shown in Table 2.

[0130] 1. Build subsurface artificial wetlands

[0131] 1-1) Excavation of constructed wetland bed

[0132] A subsurface artificial wetland bed was constructed in the filter cloth filter workshop of a sewage treatment plant in Changge City. The size of the wetland bed was: length×width×height (80cm×30cm×100cm), and the depth of the wetland bed was 100cm (that is, the wetland planting area , corn cob packing area, and the sum of the heights of the sulfur packing area is 100cm).

[0133] 1-2) Preparation of filler

[0134] 1-2A) Mix sulfur, limestone, zeolite and volcanic rock with a particle size of 30 to 35 mm evenly to prepare the filler in the sulfur packing area, that is, sulfur / limestone / zeolite / volcanic rock filler, wherein sulfur, limestone, ...

Embodiment 3

[0153] In addition to step 3) the influent flow rate during the system operation is 555mL / min, and the hydraulic retention time of the sewage in the subsurface constructed wetland is 15h (among them, the hydraulic retention time of the corn cob filling area is 10h, and the hydraulic retention time of the sulfur filling area is 5h ), the influent pH was basically maintained at 7.42-7.45, the DO was basically maintained between 2.15-2.45, and the rest were the same as in Example 2.

[0154] See Table 2 for the measurement results of the effluent water quality (COD, nitrate, ammonia nitrogen, total phosphorus) after the sewage is treated by the subsurface flow constructed wetland. As can be seen from the water quality measurement results in Table 2: adopting the subsurface flow constructed wetland of the present invention to treat municipal sewage, the removal effect is remarkable, and the denitrification effect is obvious, wherein NO 3 The removal rate of -N can reach 97.38%; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com