Active denitrification nitrogen removal membrane bioreactor sewage treatment equipment and system

A technology of membrane bioreactor and sewage treatment equipment, which is applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of dependence on denitrification effect, and improve denitrification Nitrogen capacity and nitrogen removal efficiency are high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

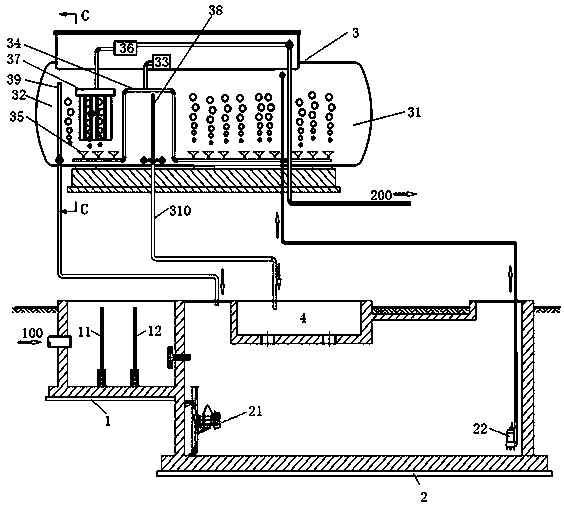

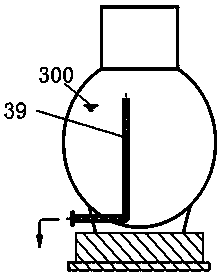

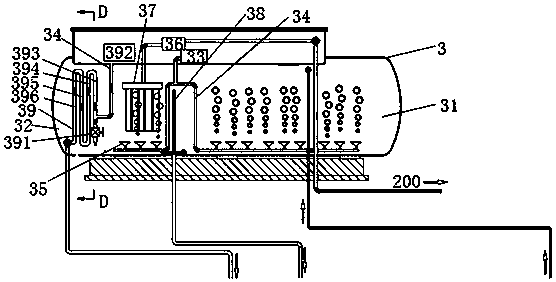

[0032] image 3 with Figure 4 Schematic diagram of the structure of the active denitrification and denitrification membrane bioreactor sewage treatment equipment provided in this embodiment. The active denitrification and denitrification membrane bioreactor sewage treatment equipment includes a tank body, which is divided into good The oxygen zone 31 and the membrane zone 32 , and the aerobic zone 31 and the membrane zone 32 are separated by a partition 38 . The aerobic zone 31 is provided with activated sludge for converting the pollutant ammonia nitrogen in the sewage into nitrate nitrogen, and the sewage inlet is located on the side of the aerobic zone 31 . Membrane zone 32 is provided with MBR diaphragm 37 for solid-liquid separation, the top of MBR diaphragm 37 is connected to the clear water discharge pipe, and the produced water pump 36 is installed on the clean water discharge pipe. One end of the nitrifying liquid return pipe 39 is inserted into the membrane area 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com