Halogen-free epoxy resin composition, laminated plate and printed circuit board

A halogen epoxy resin, epoxy resin technology, applied in the field of laminates and printed circuit boards, can solve problems such as increased hygroscopicity and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

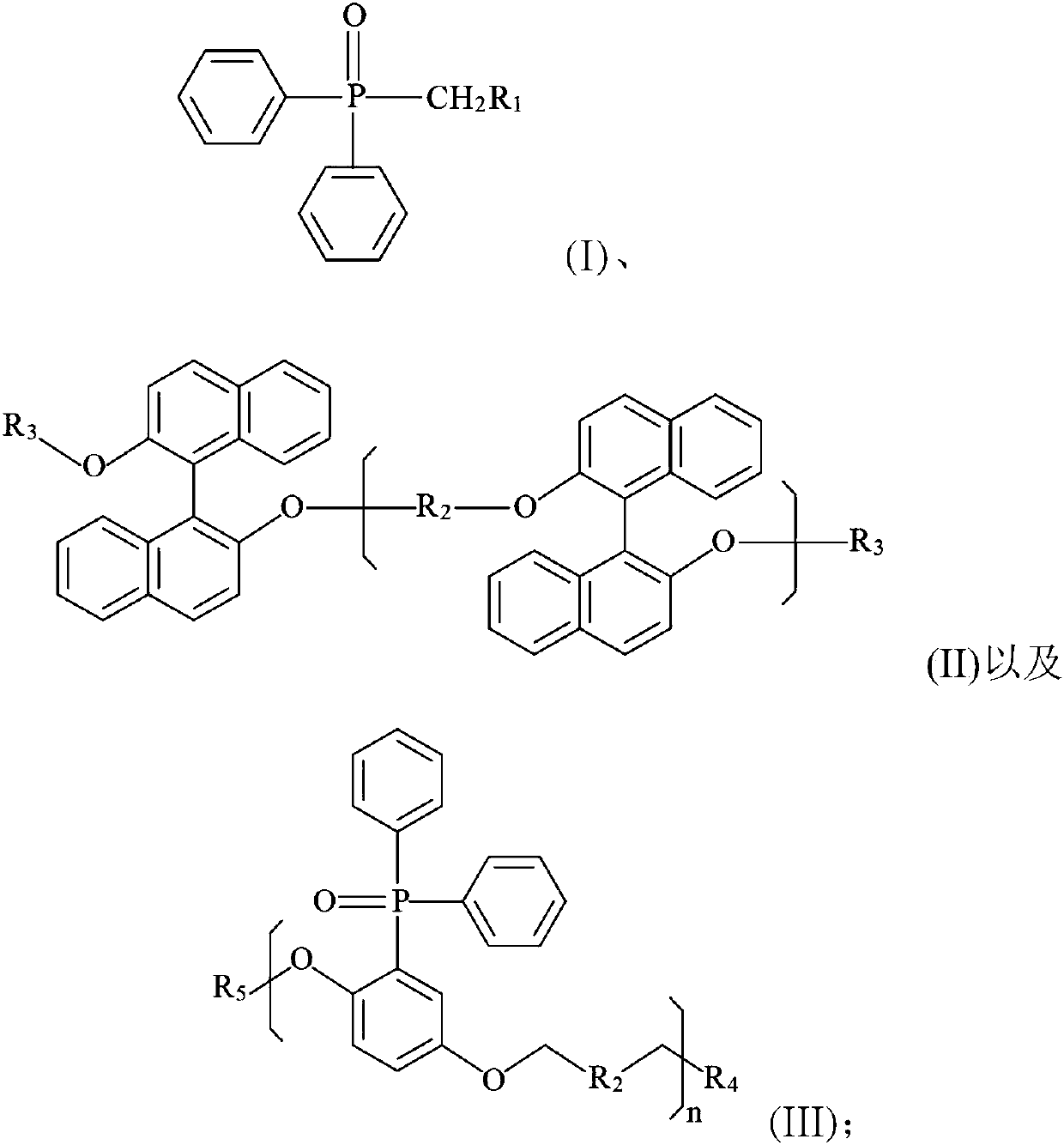

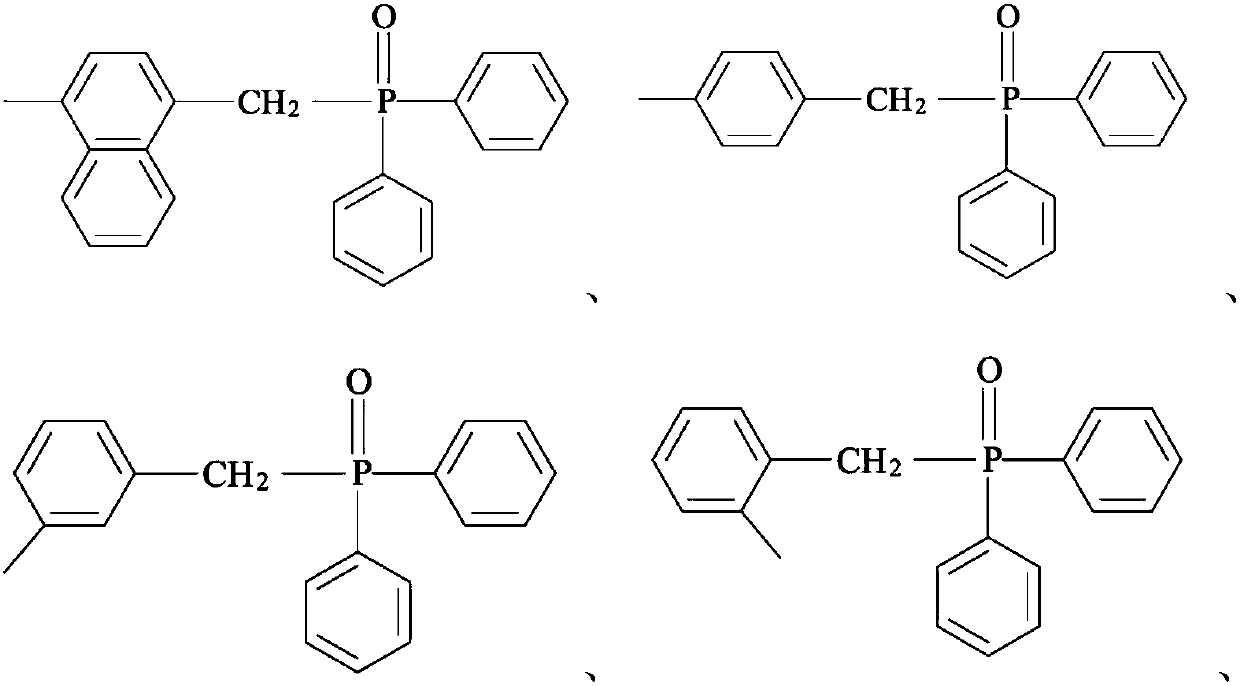

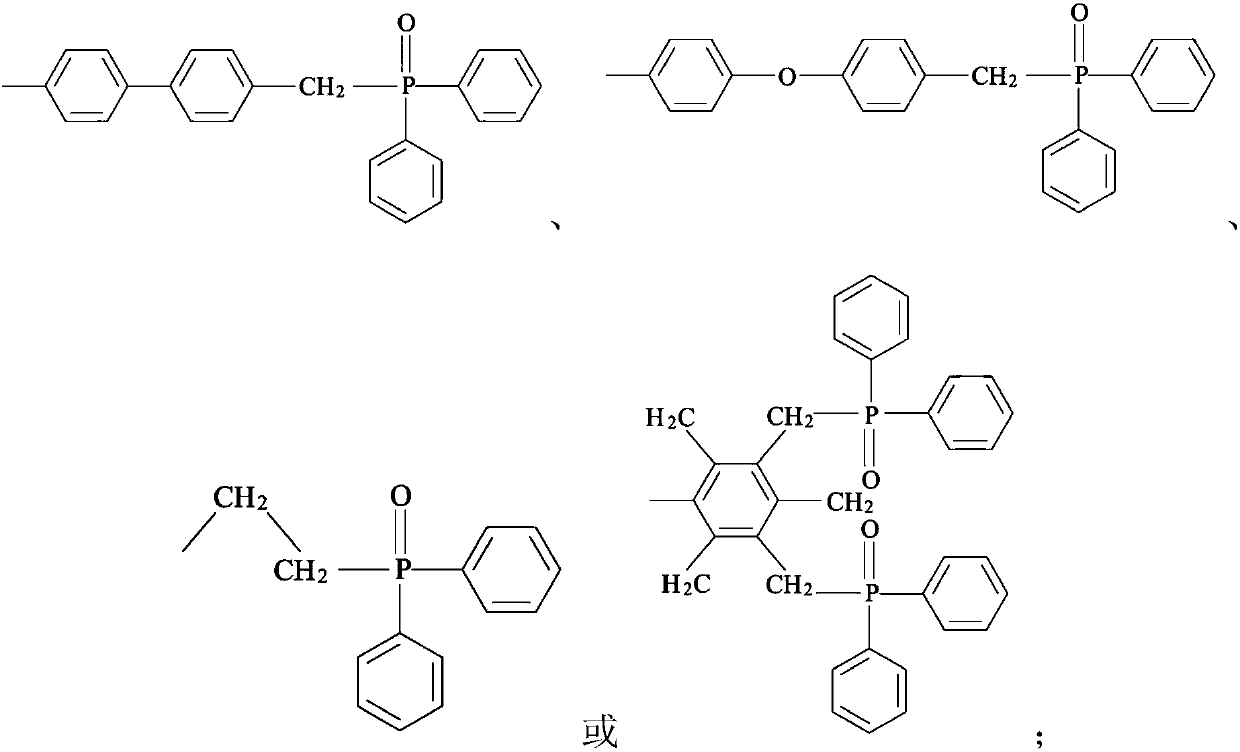

Method used

Image

Examples

Embodiment

[0068] The following examples E-1 to E-5 use the halogen-free epoxy resin composition of the present invention to manufacture prepregs in a continuous process. Usually glass fiber cloth is used as the base material. Rolled fiberglass cloth is passed continuously through a series of rollers into a gluing tank filled with the halogen-free epoxy resin composition of the present invention. In the gluing tank, the glass fiber cloth is fully soaked by the resin composition, and then the excess resin composition is scraped off by the metering roller, and then baked in the gluing furnace for a certain period of time to evaporate the solvent and solidify the resin to a certain extent, cool and collect. Roll to form a prepreg, and then take the prepreg prepared in the above batch, take four prepregs and two 18μm copper foils from the same batch, and laminate them in the order of copper foil, four prepregs, and copper foil. The copper foil substrate was then formed by pressing at 220° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com