High-stability rubber pipe resistant to water-absorption aging for automobiles and preparation process of rubber pipe

A high-stability, aging rubber technology, applied in the field of automotive rubber pipes, can solve problems such as affecting performance and rubber cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

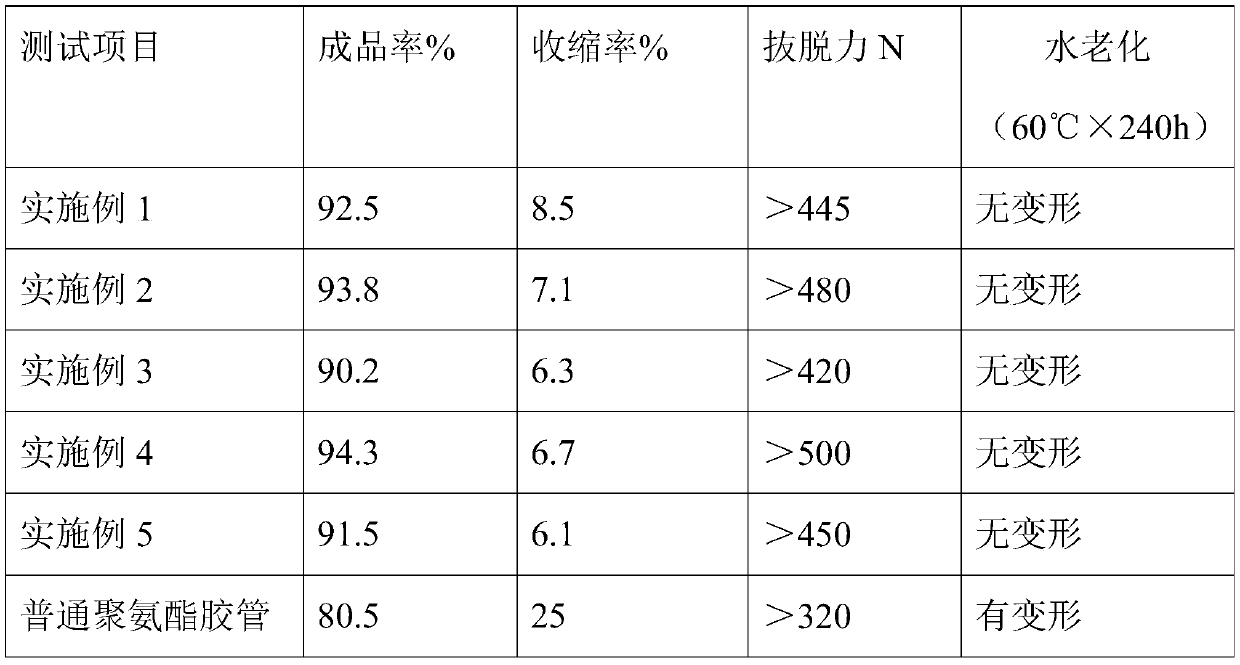

Examples

Embodiment 1

[0019] A kind of preparation process of high-stability and difficult-to-absorb aging rubber tube for automobile, comprising the following steps:

[0020] S1. Put 20 parts of polytetrahydrofuran diol, 2 parts of cyclopolypropylene oxide ether triol, and 0.5 part of polyvinyl alcohol into the reaction kettle by weight, heat to 90°C under vacuum and stirring, and cool down to Add 2 parts of toluene diisocyanate and 3 parts of 1,5-naphthalene diisocyanate at 40°C, stir at 85°C for 40 minutes, let stand for 20 hours, and dehydrate to obtain prefabricated polyurethane;

[0021] S2. Add 12 parts of acrylonitrile-butadiene-styrene and 1 part of chain extender di-o-chlorodiphenylamine methane to the prefabricated polyurethane, heat and melt and stir evenly to obtain a premix;

[0022] S3. Send the premixed material into the twin-screw extruder for extrusion. The temperature of each stage of the extruder is as follows: the temperature of the first zone of the barrel is 170°C, the temper...

Embodiment 2

[0024] A kind of preparation process of high-stability and difficult-to-absorb aging rubber tube for automobile, comprising the following steps:

[0025] S1. Put 10 parts of polytetrahydrofuran diol, 6 parts of cyclopolypropylene oxide ether triol, and 0.1 part of polyvinyl alcohol into the reaction kettle by weight, heat to 100°C under vacuum and stirring, and cool down to 100°C after dehydration. Add 6 parts of toluene diisocyanate and 1 part of 1,5-naphthalene diisocyanate at 30°C, stir at 92°C for 20 minutes, let stand for 40 hours, and dehydrate to obtain prefabricated polyurethane;

[0026] S2. Add 4 parts of acrylonitrile-butadiene-styrene and 3 parts of chain extender di-o-chlorodiphenylamine methane to the prefabricated polyurethane, heat and melt and stir evenly to obtain a premix;

[0027] S3. Send the premixed material into the twin-screw extruder for extrusion. The temperature of each stage of the extruder is as follows: the temperature of the first zone of the ba...

Embodiment 3

[0029] A kind of preparation process of high-stability and difficult-to-absorb aging rubber tube for automobile, comprising the following steps:

[0030] S1. Put 18 parts of polytetrahydrofuran diol, 3 parts of cyclopolypropylene oxide ether triol, and 0.4 part of polyvinyl alcohol into the reaction kettle by weight, heat to 92°C under vacuum and stirring, and cool down to Add 3 parts of toluene diisocyanate and 2.5 parts of 1,5-naphthalene diisocyanate at 37°C, stir at 86°C for 32 minutes, let stand for 22 hours, and dehydrate to obtain prefabricated polyurethane;

[0031] S2. Add 10 parts of acrylonitrile-butadiene-styrene and 1.5 parts of chain extender di-o-chlorodiphenylamine methane to the prefabricated polyurethane, heat and melt and stir evenly to obtain a premix;

[0032] S3. Send the premixed material into the twin-screw extruder for extrusion. The temperature of each stage of the extruder is as follows: the temperature of the first zone of the barrel is 168°C, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com